To achieve the automation of the sewing industry,

we are digitally transforming the center of production.

To achieve the automation

of the sewing industry,

we are digitally transforming

the center of production.

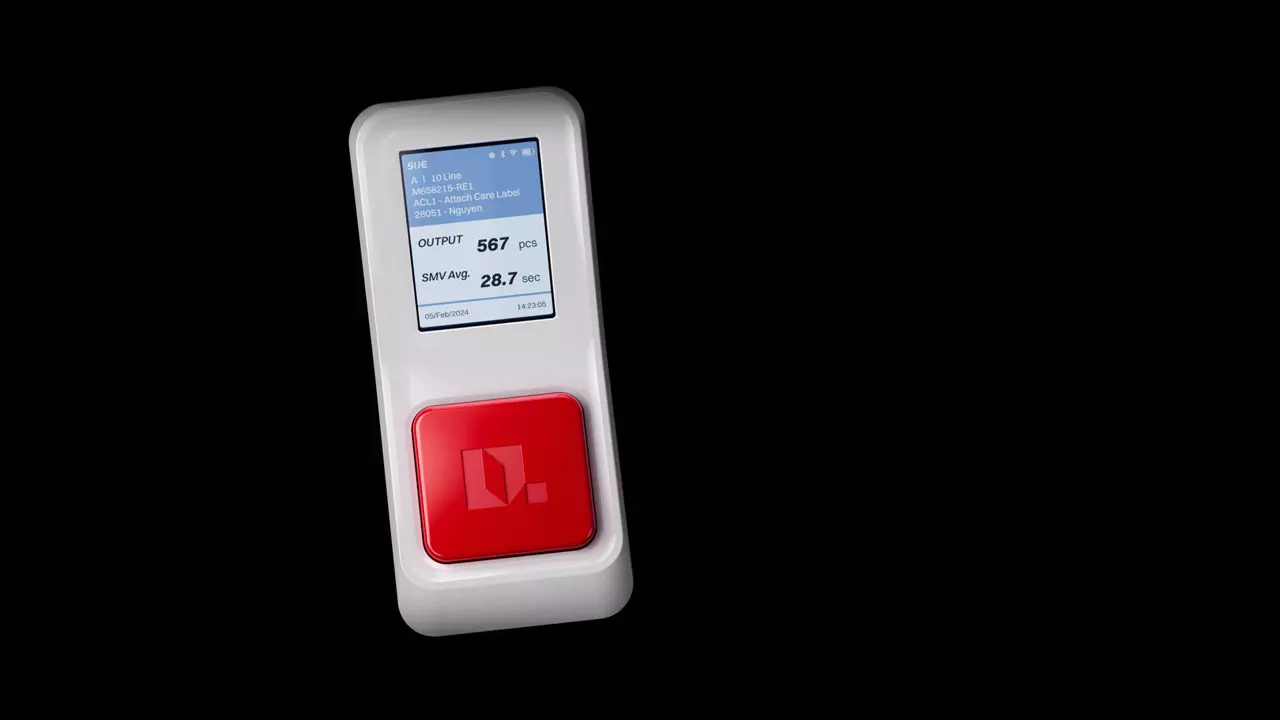

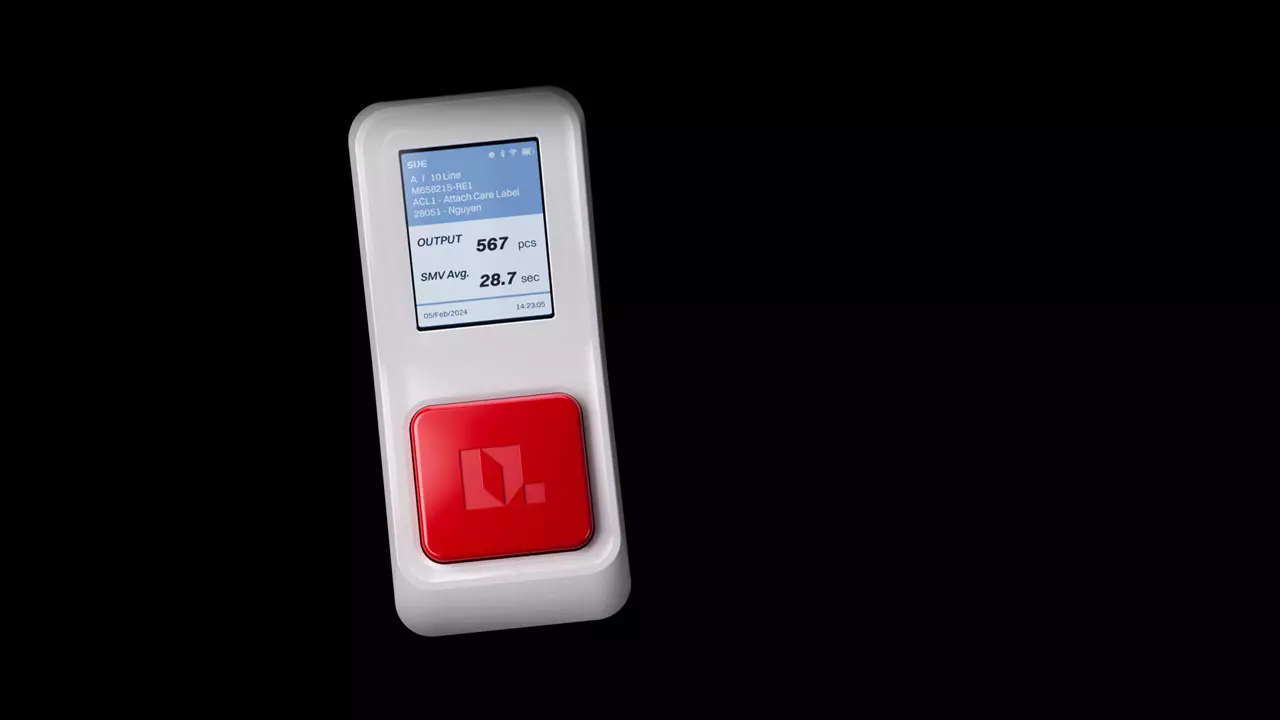

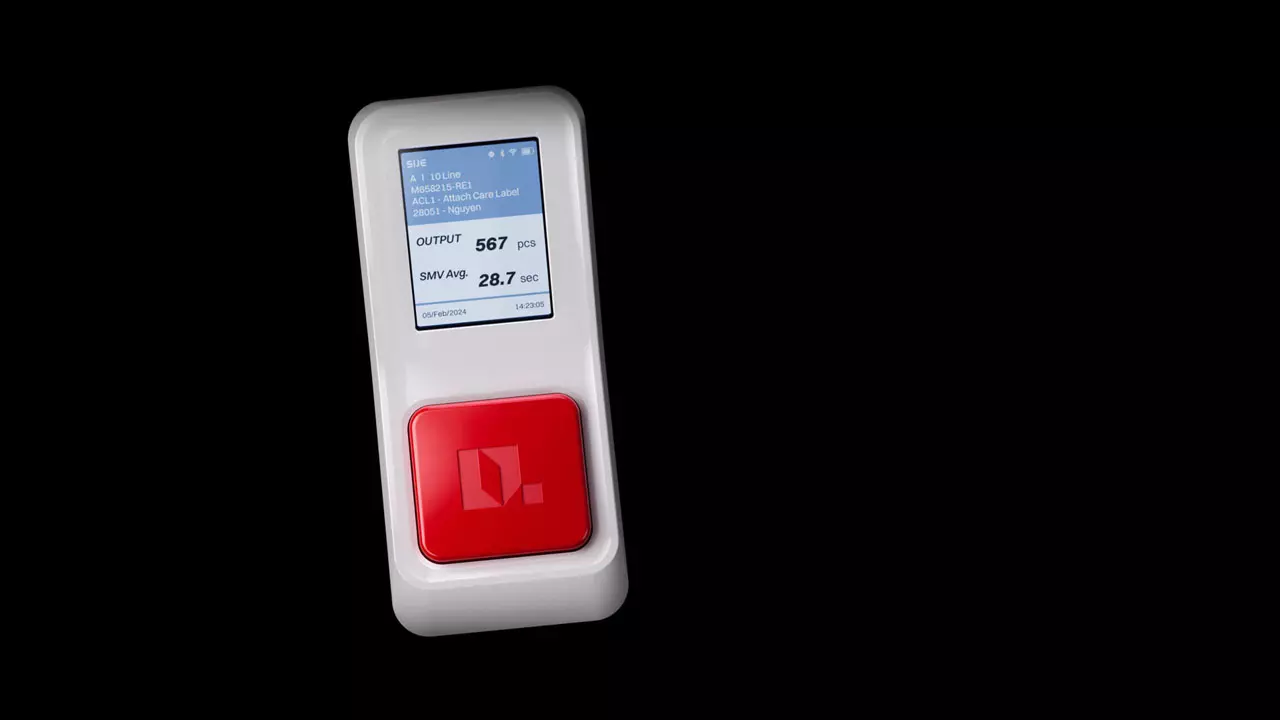

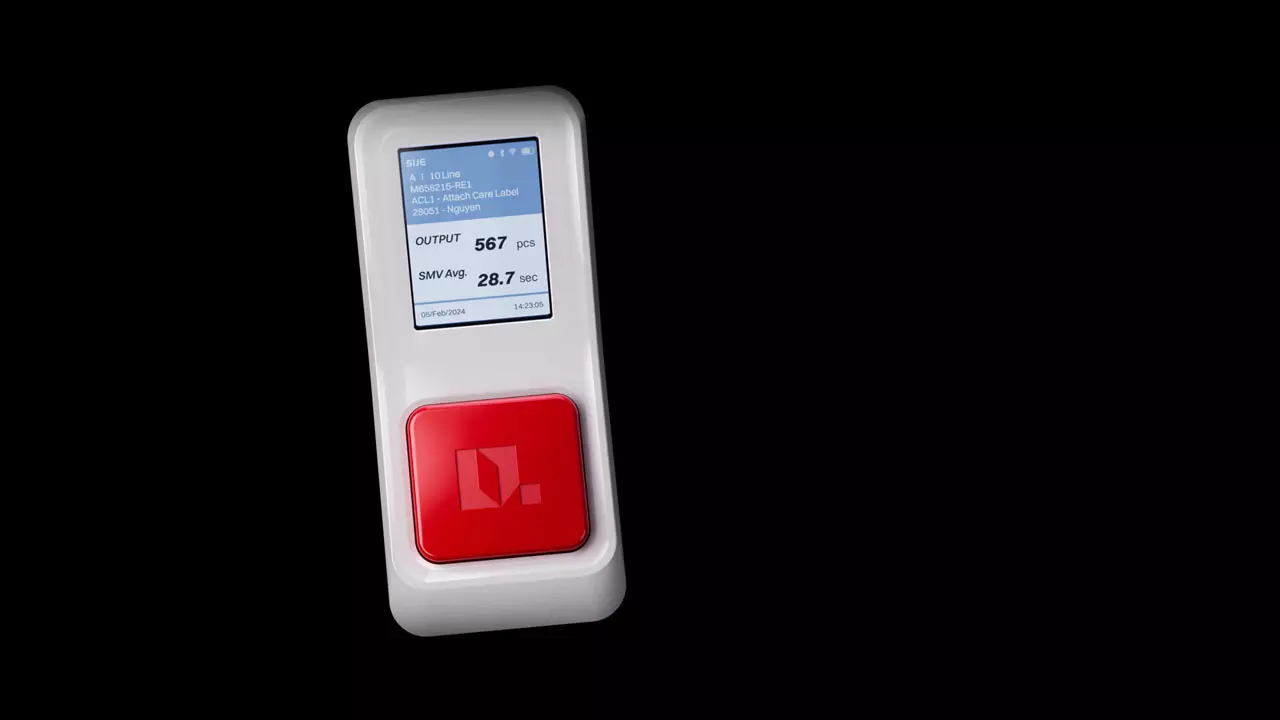

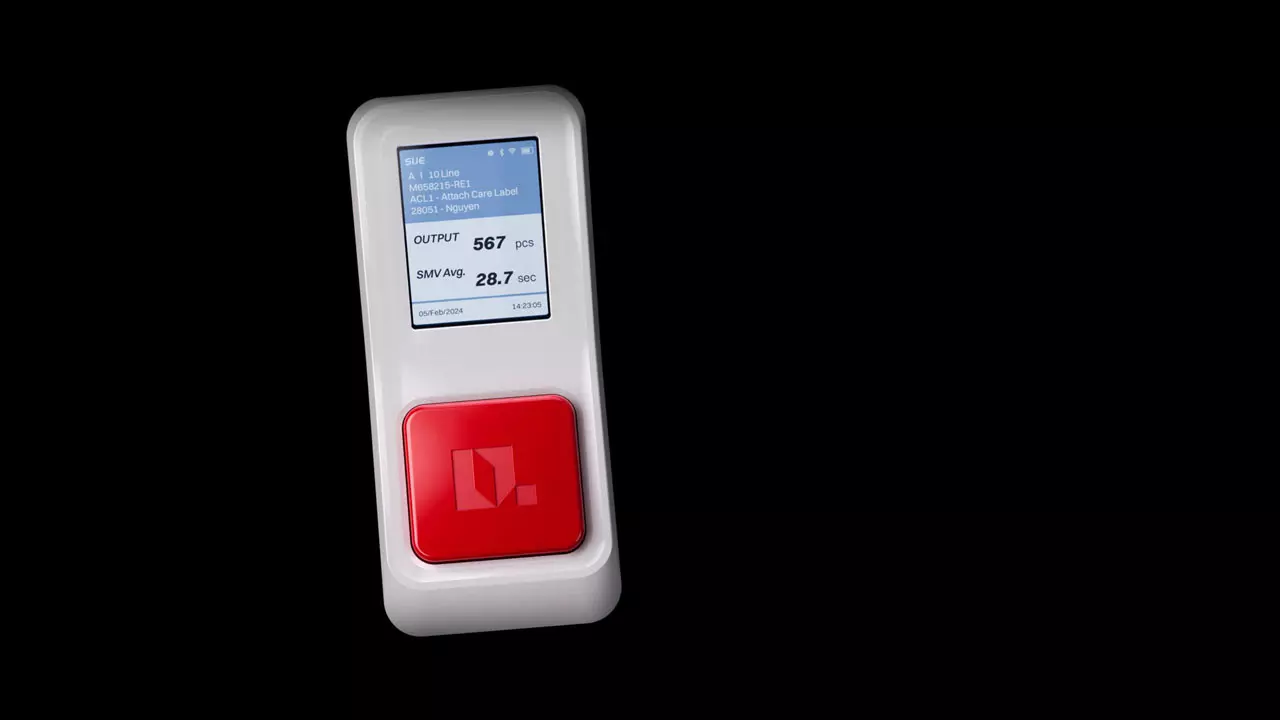

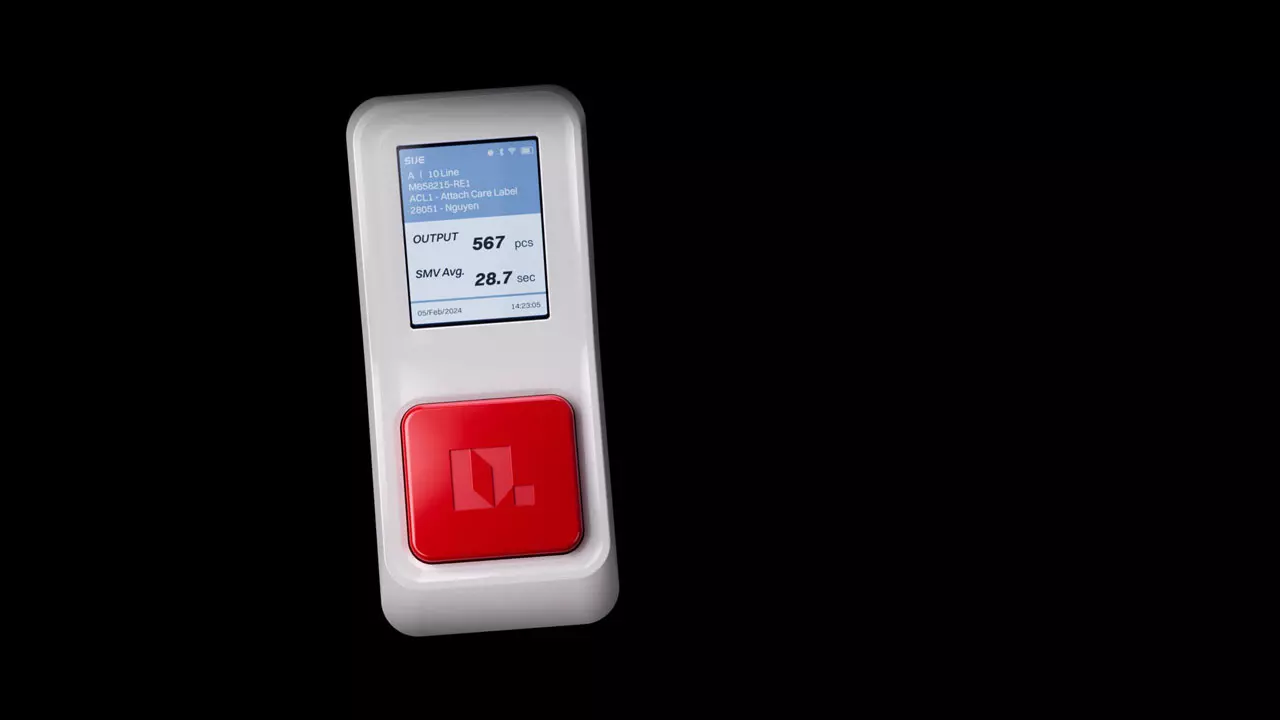

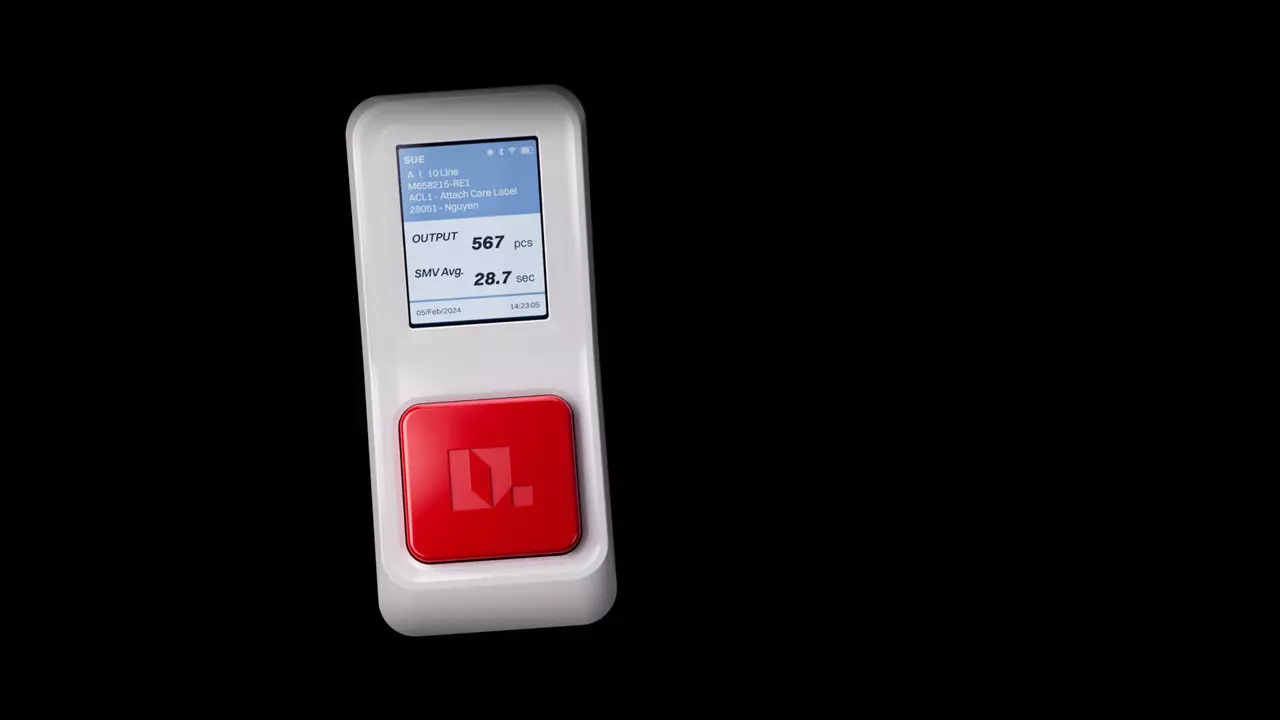

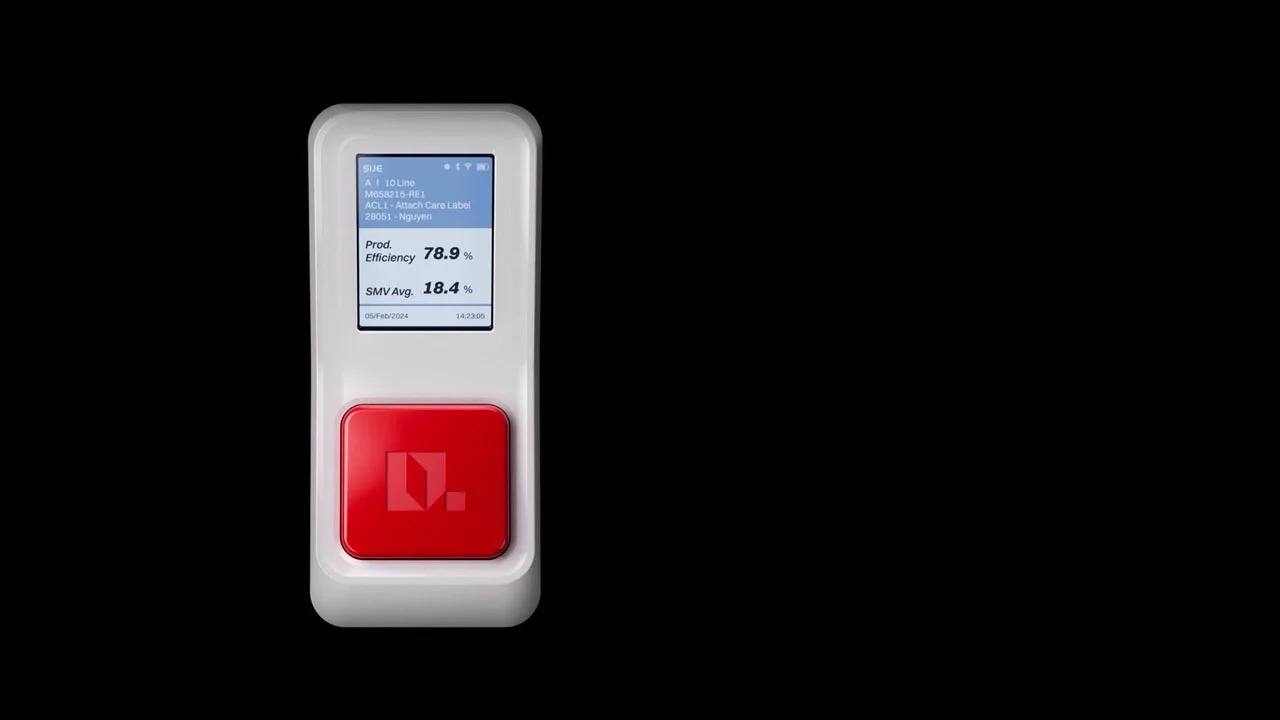

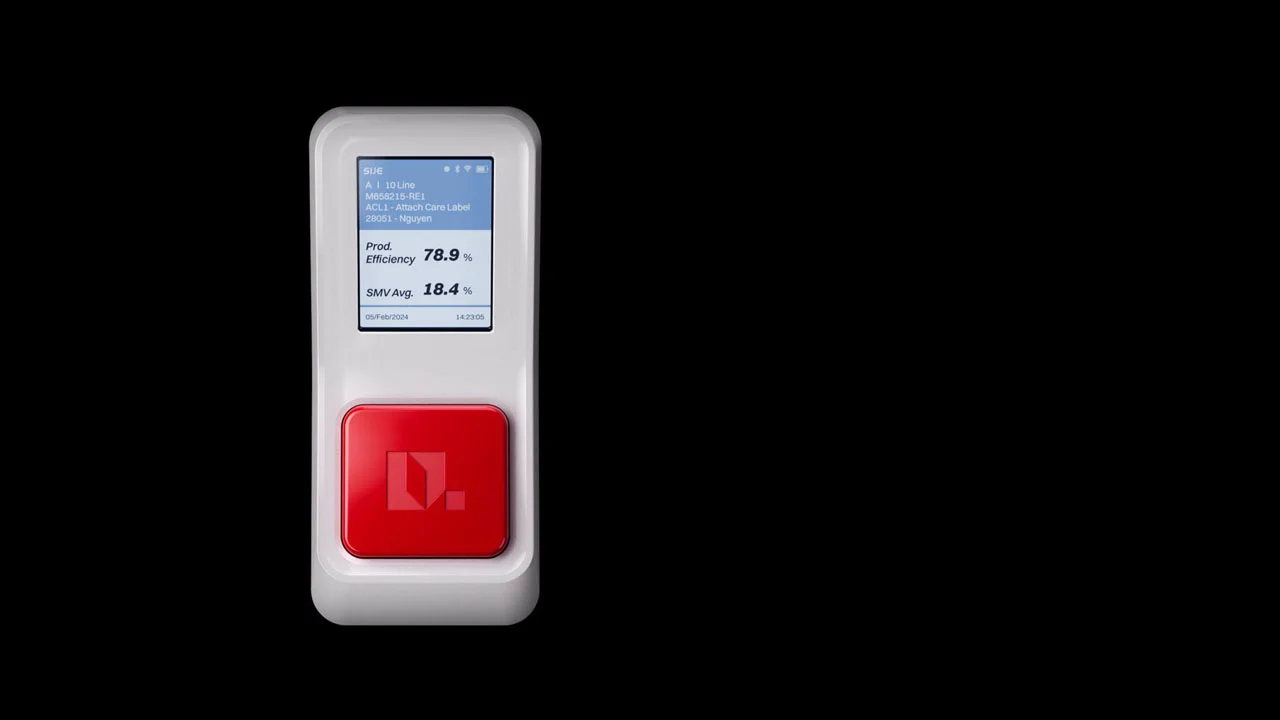

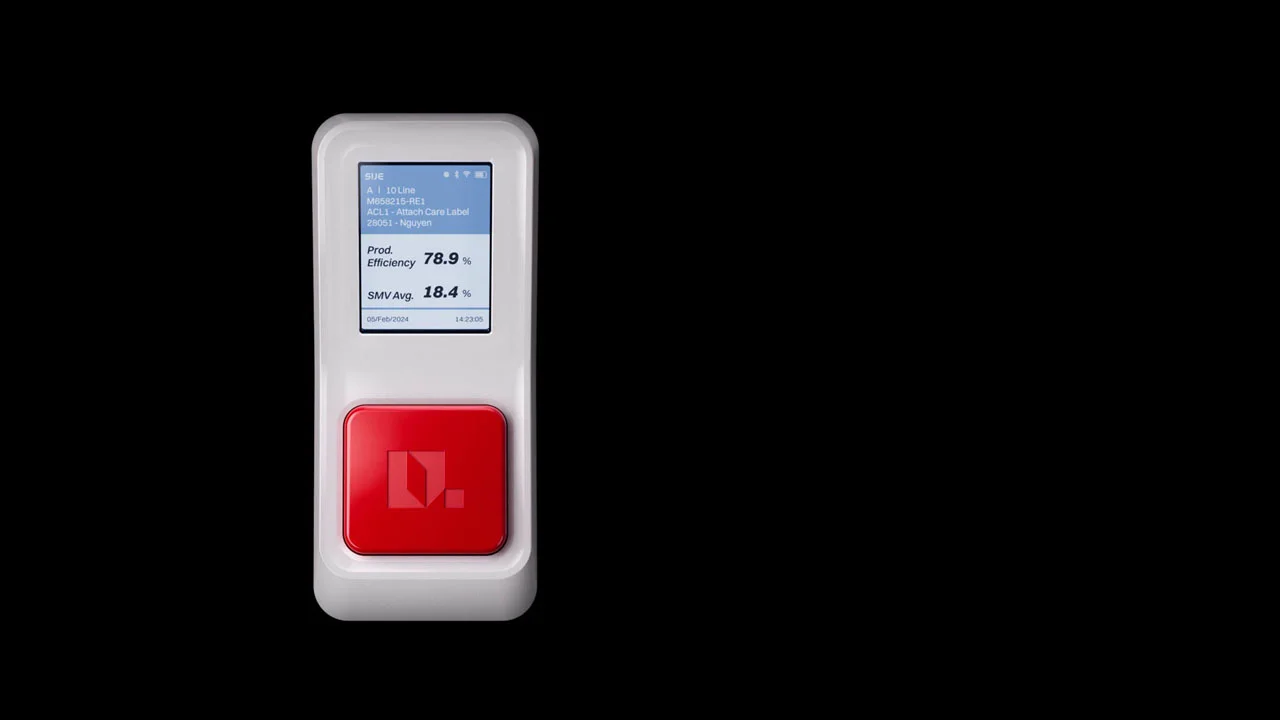

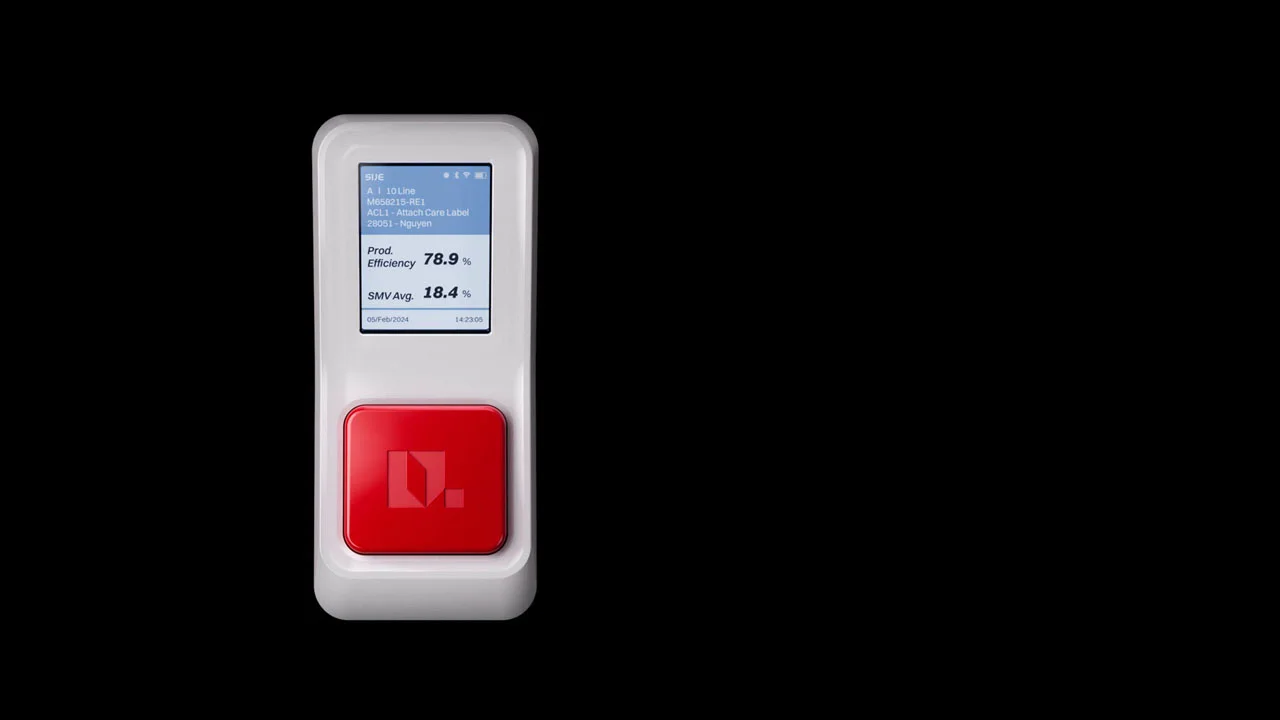

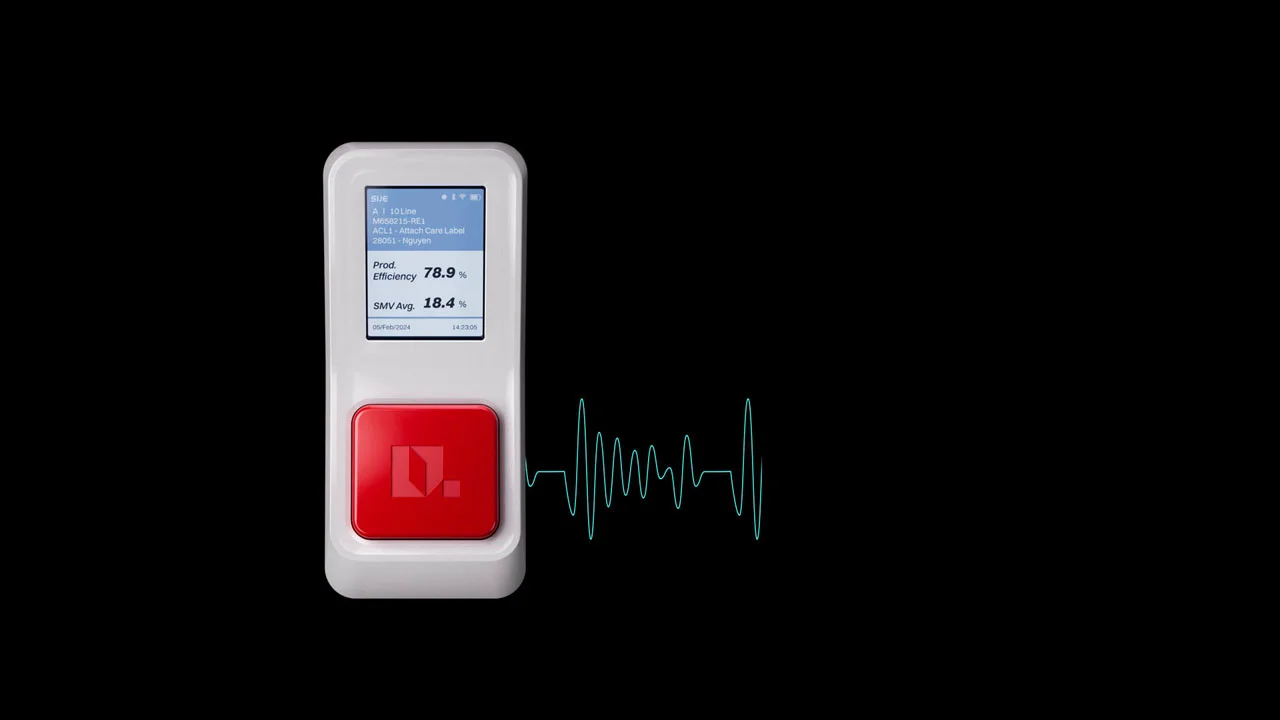

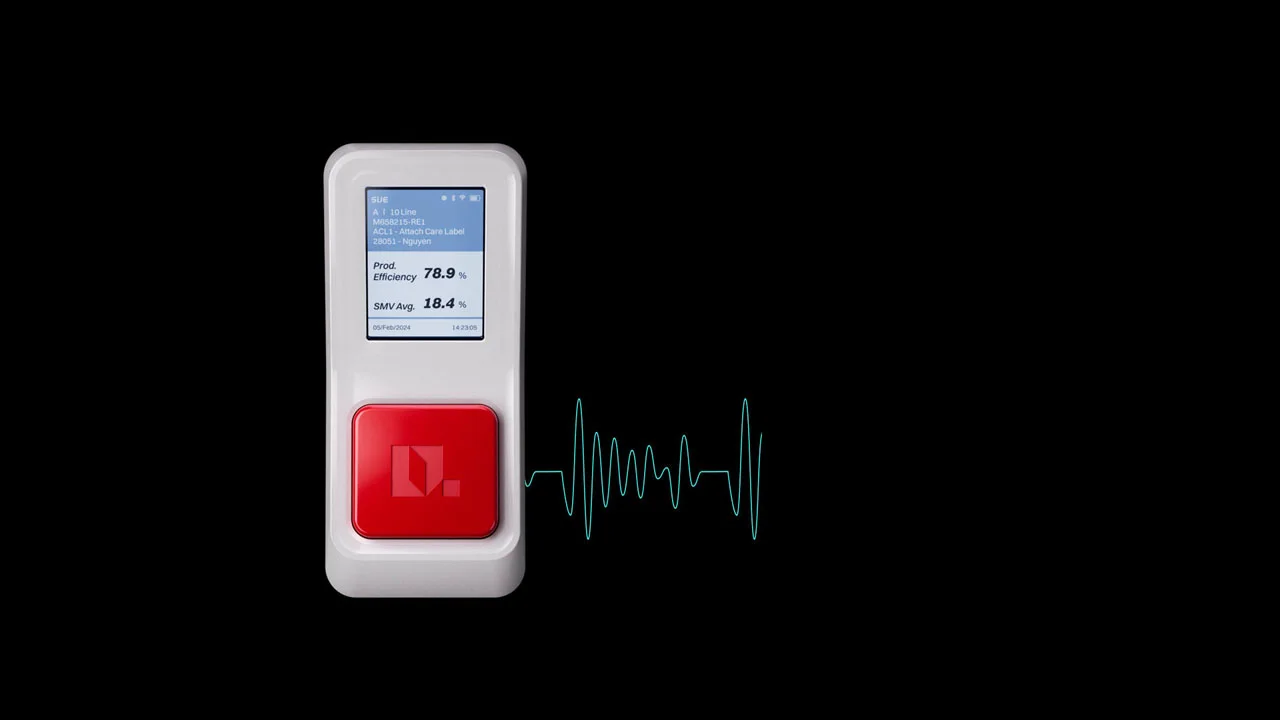

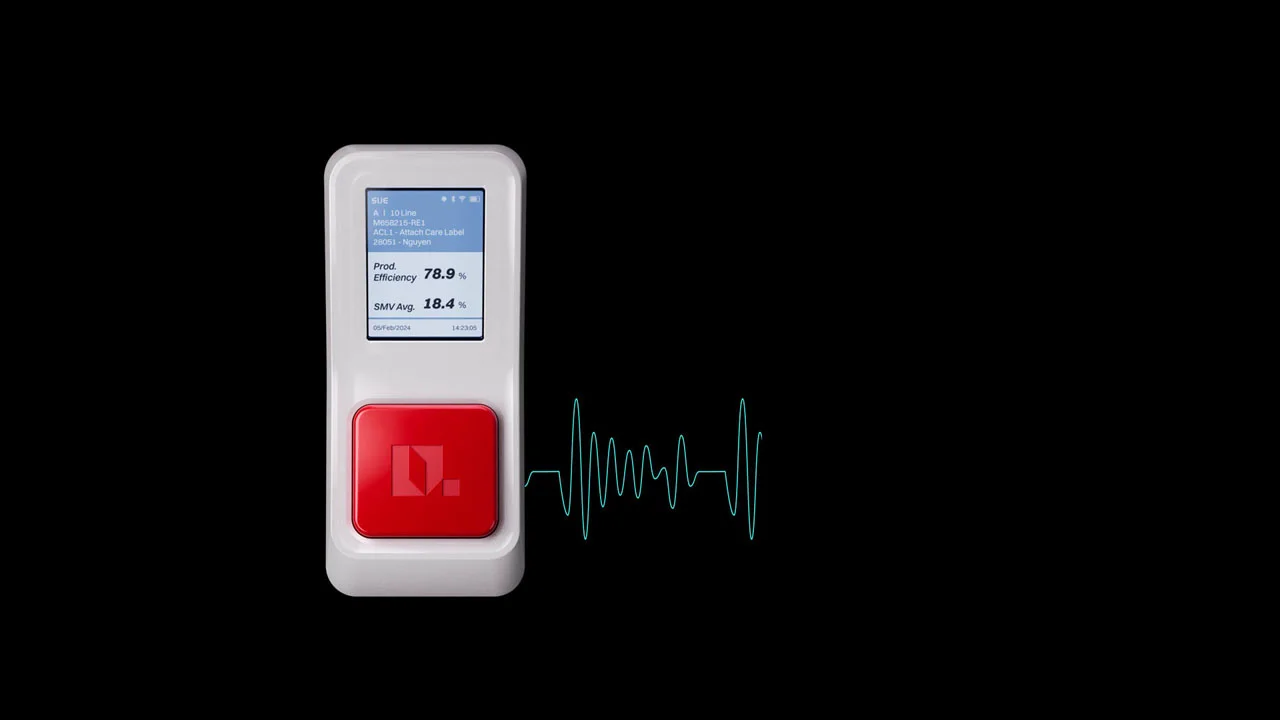

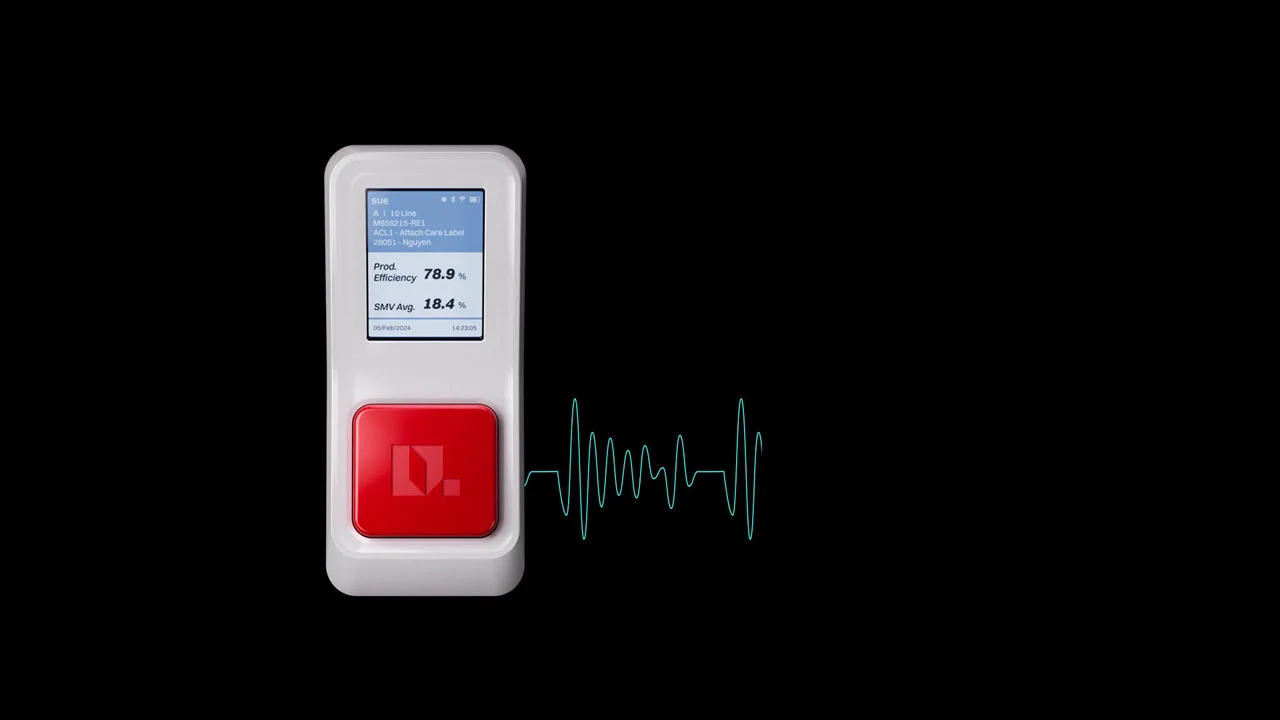

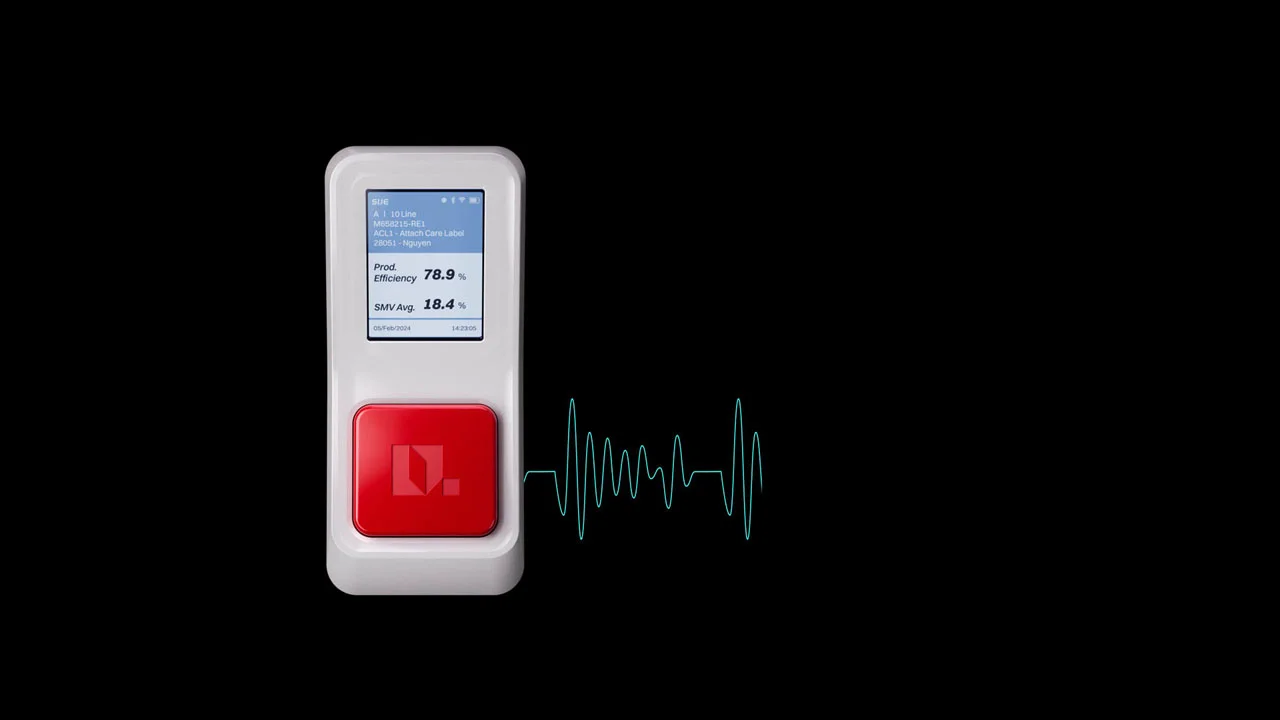

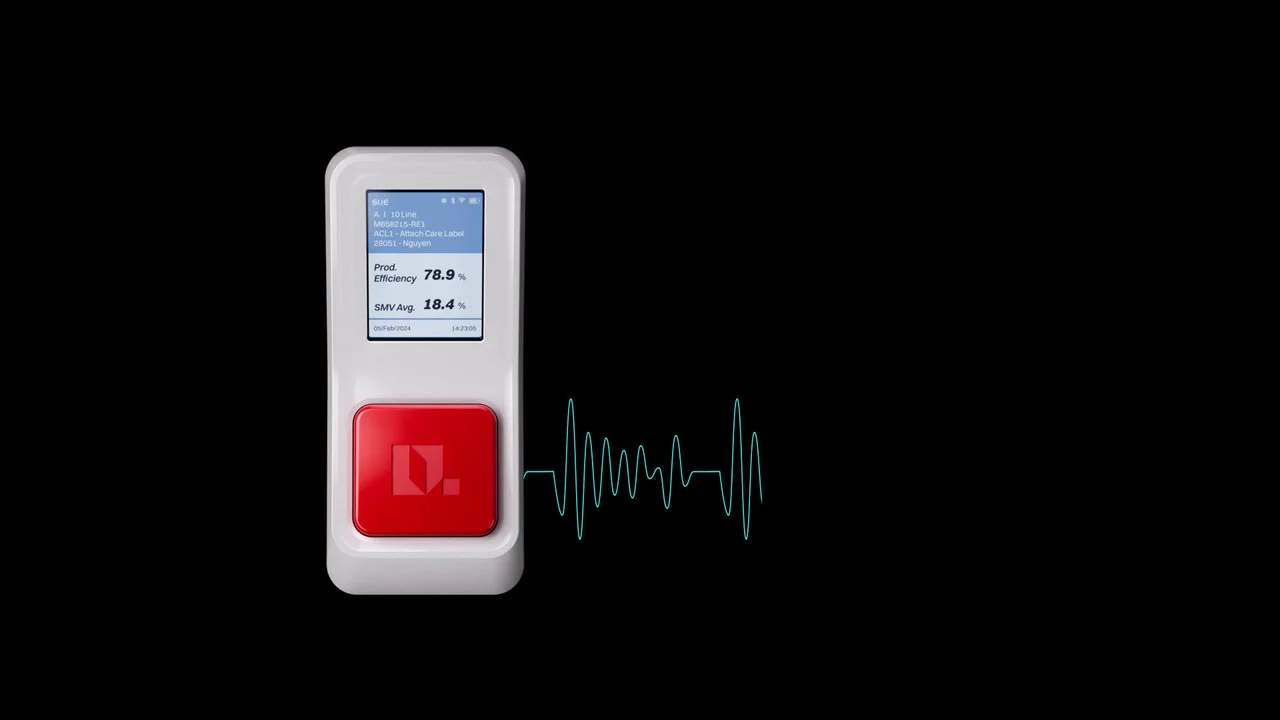

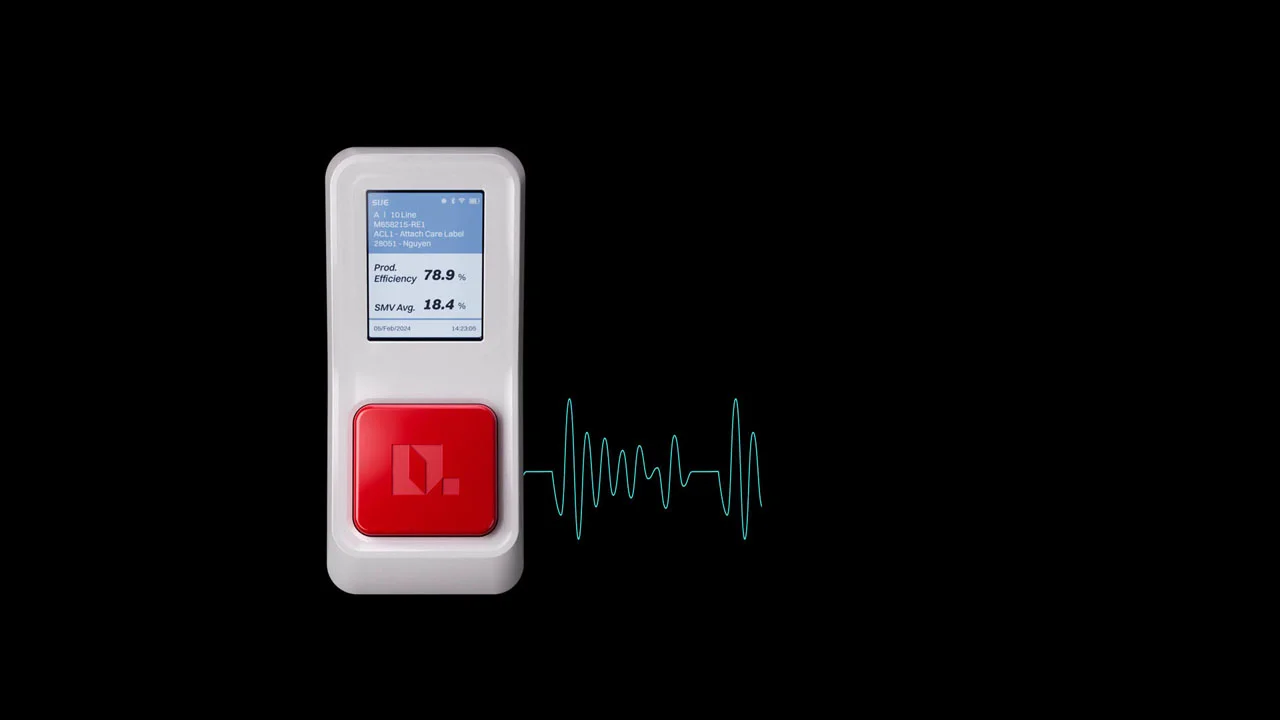

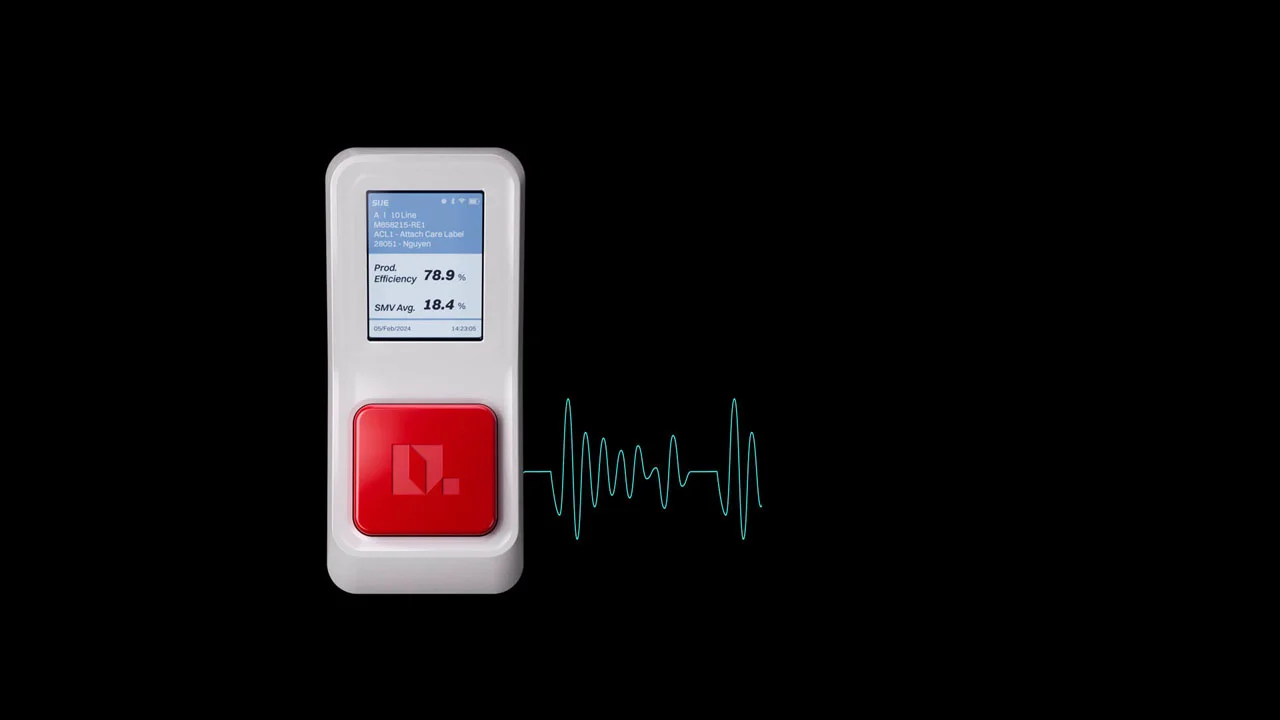

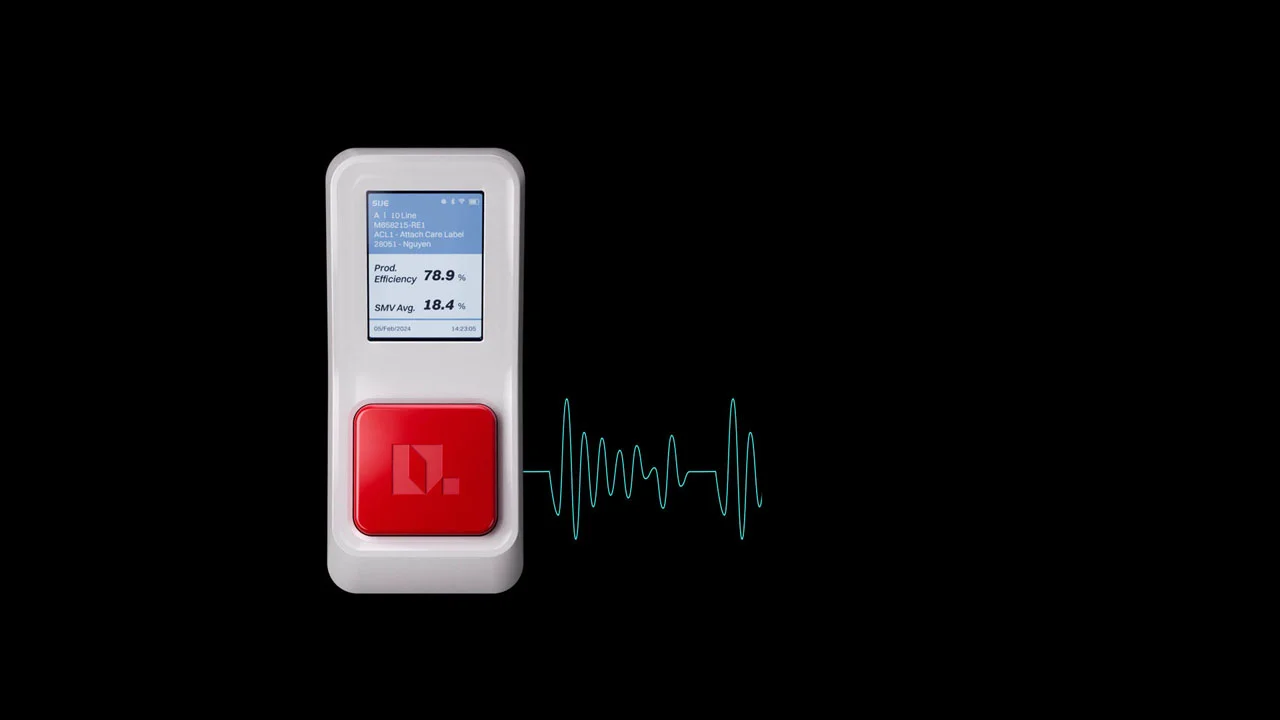

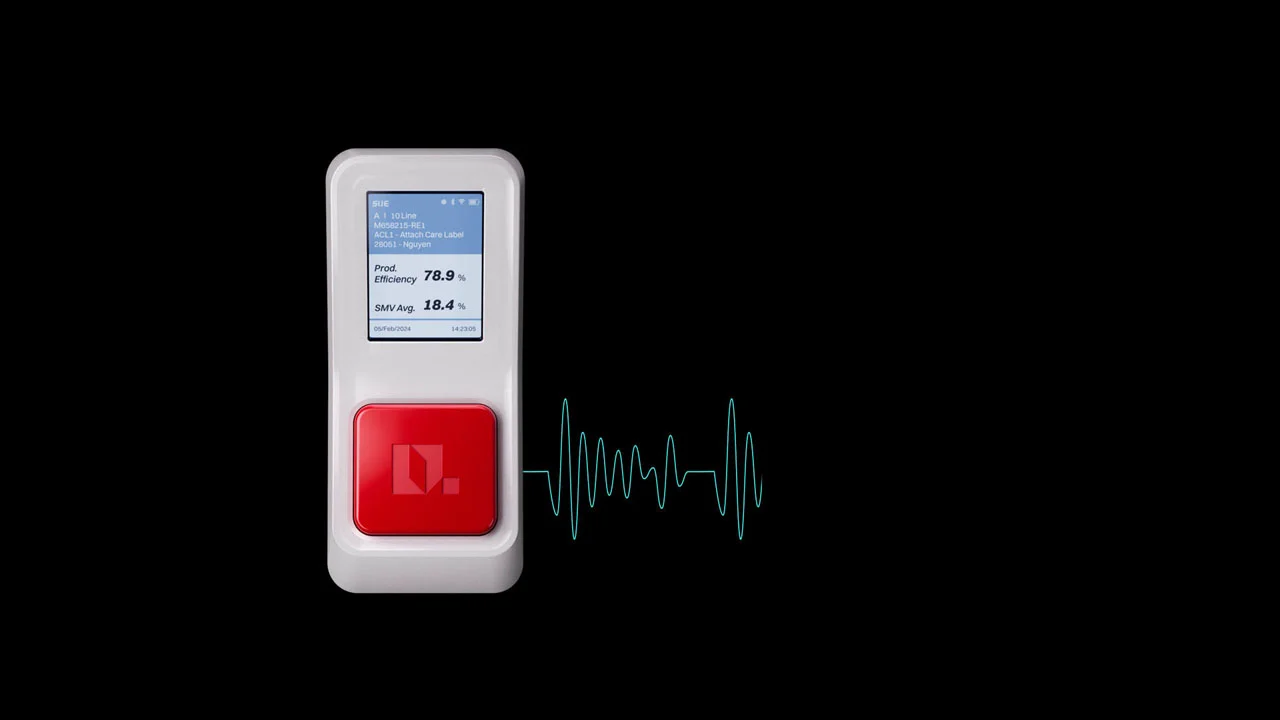

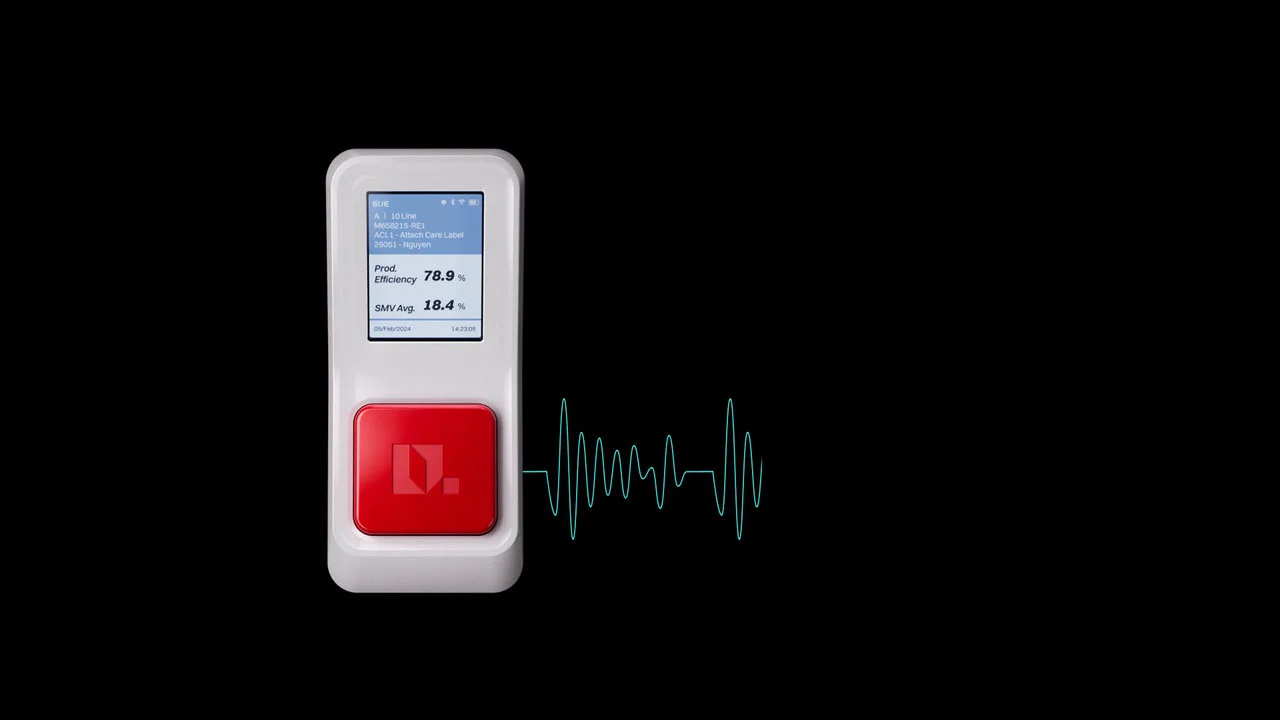

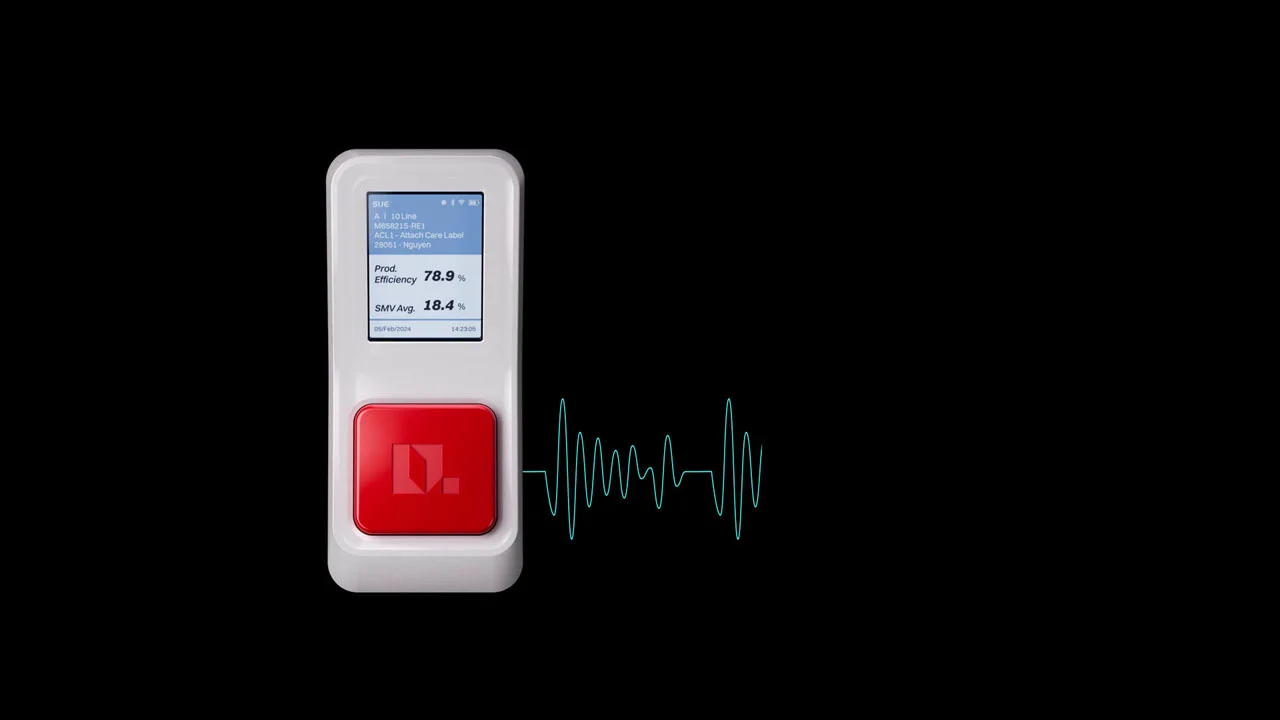

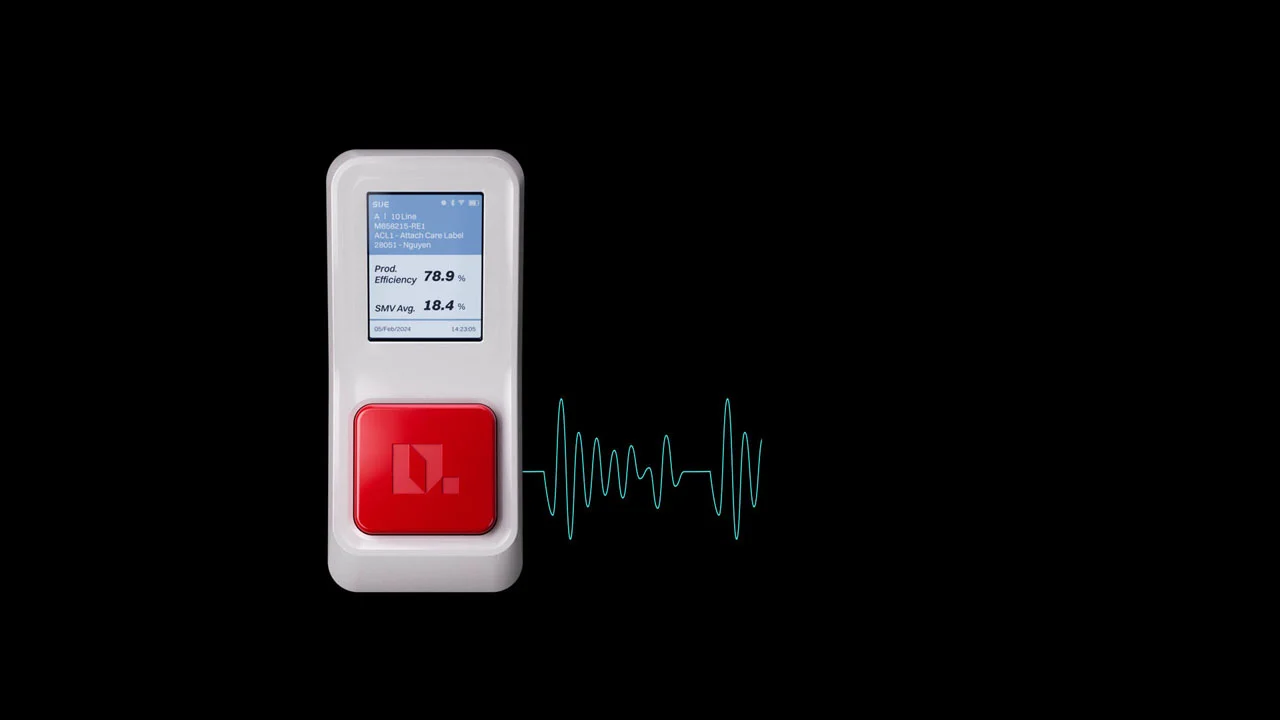

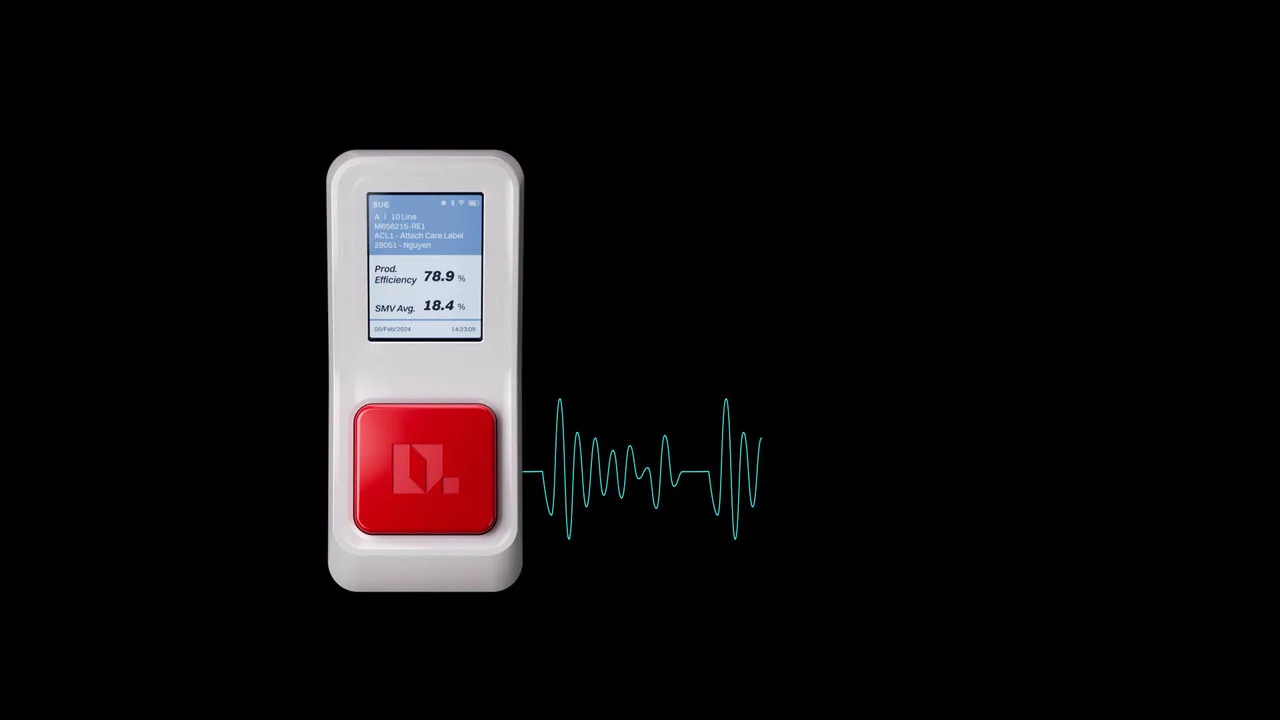

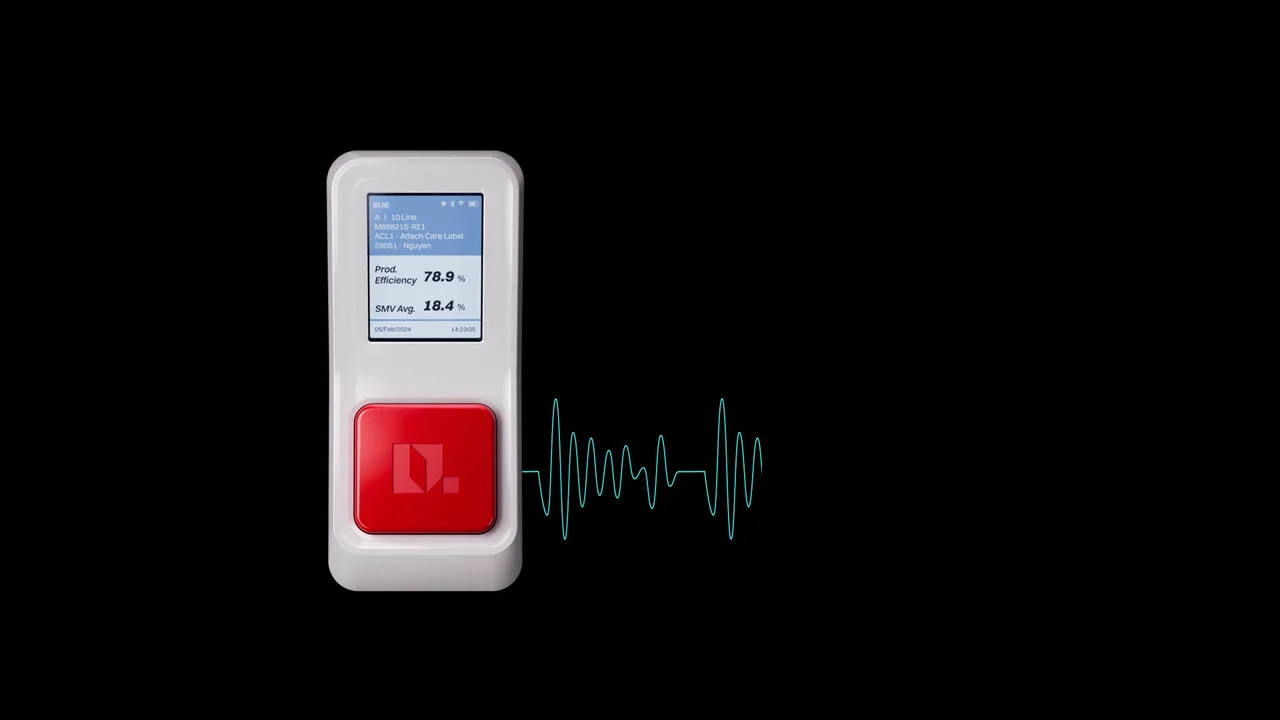

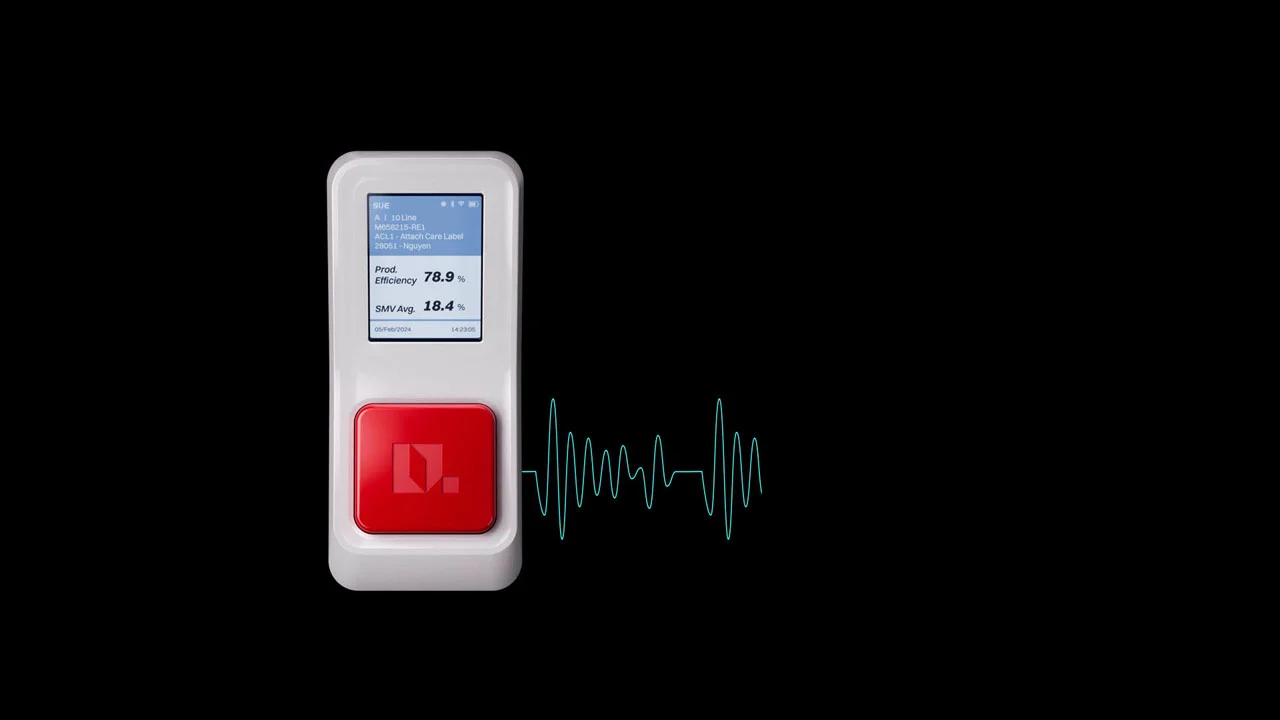

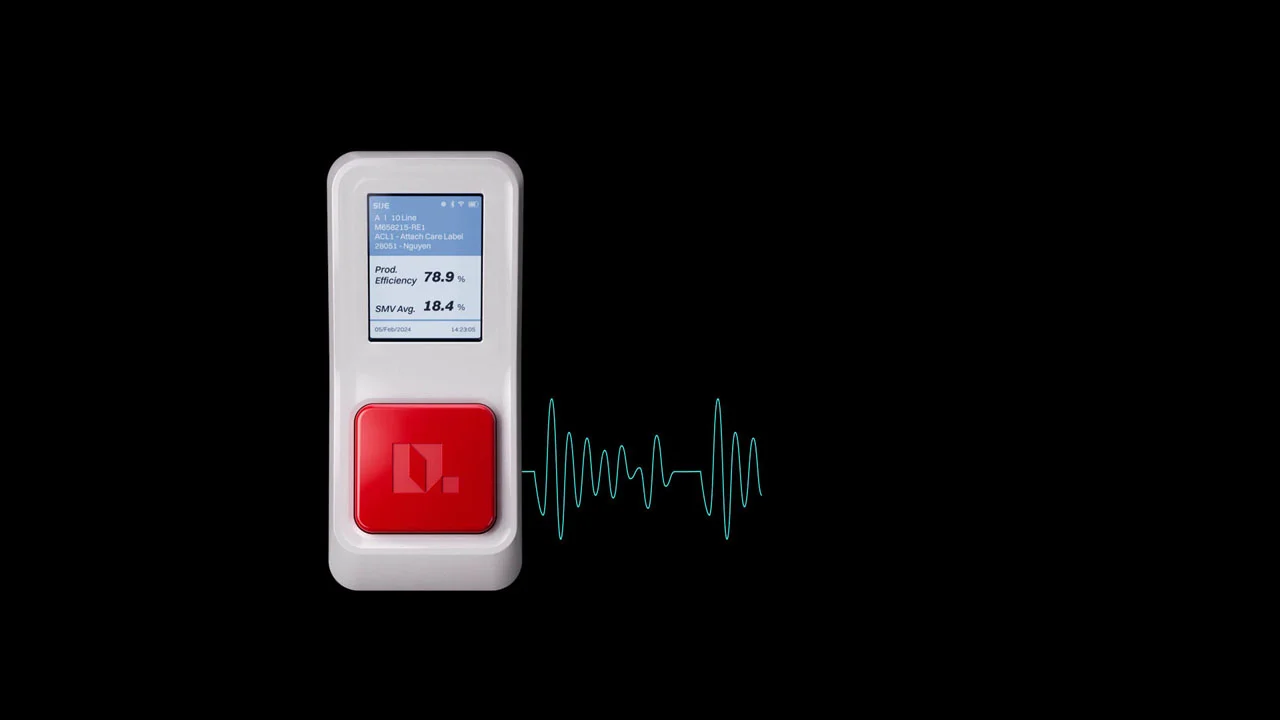

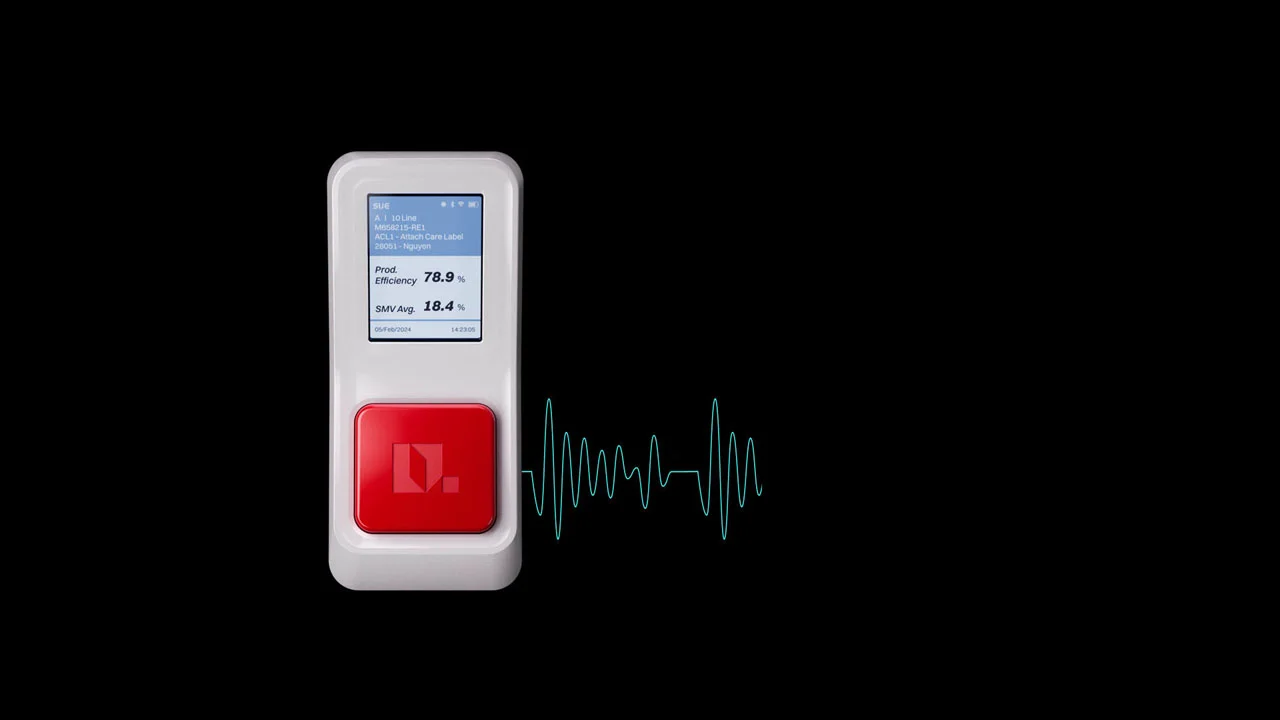

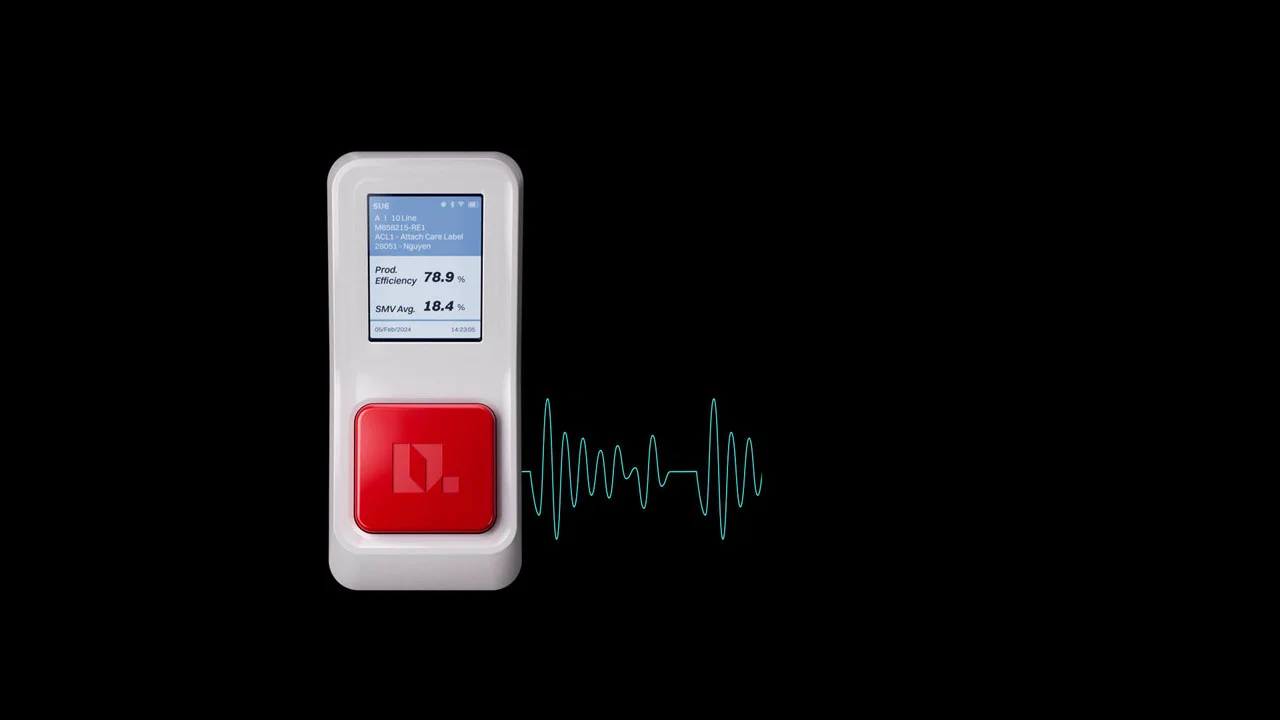

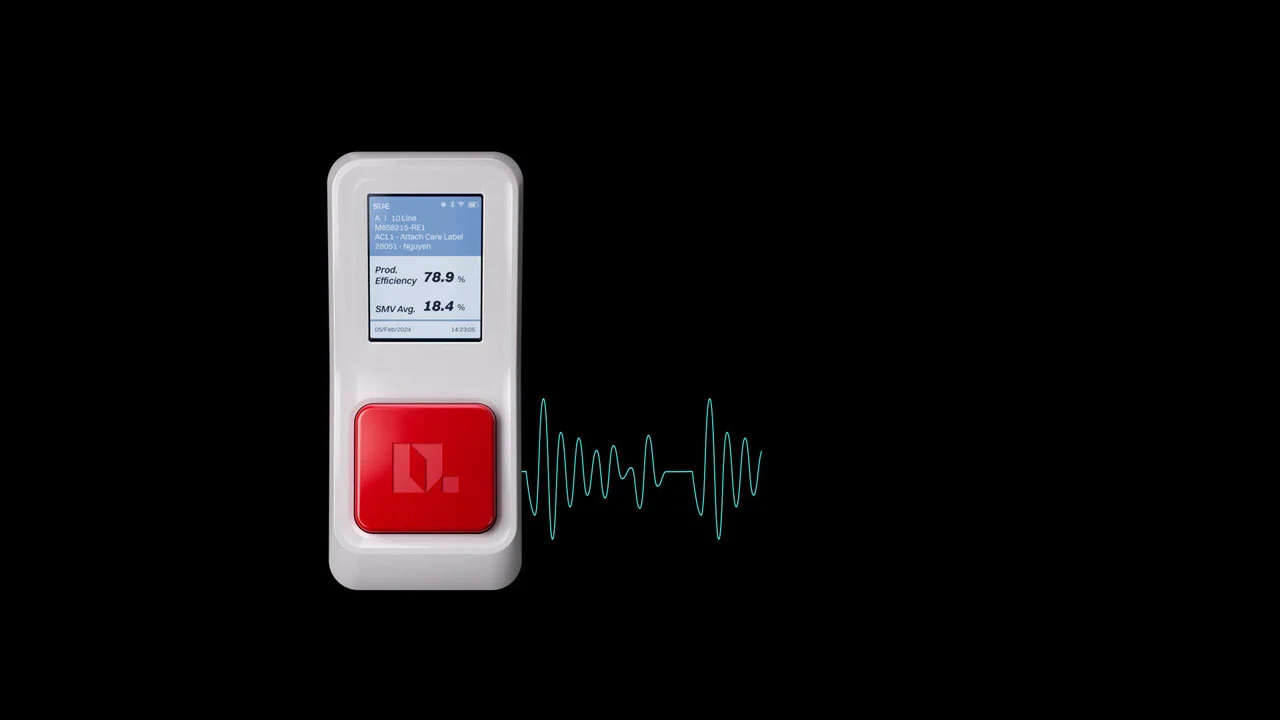

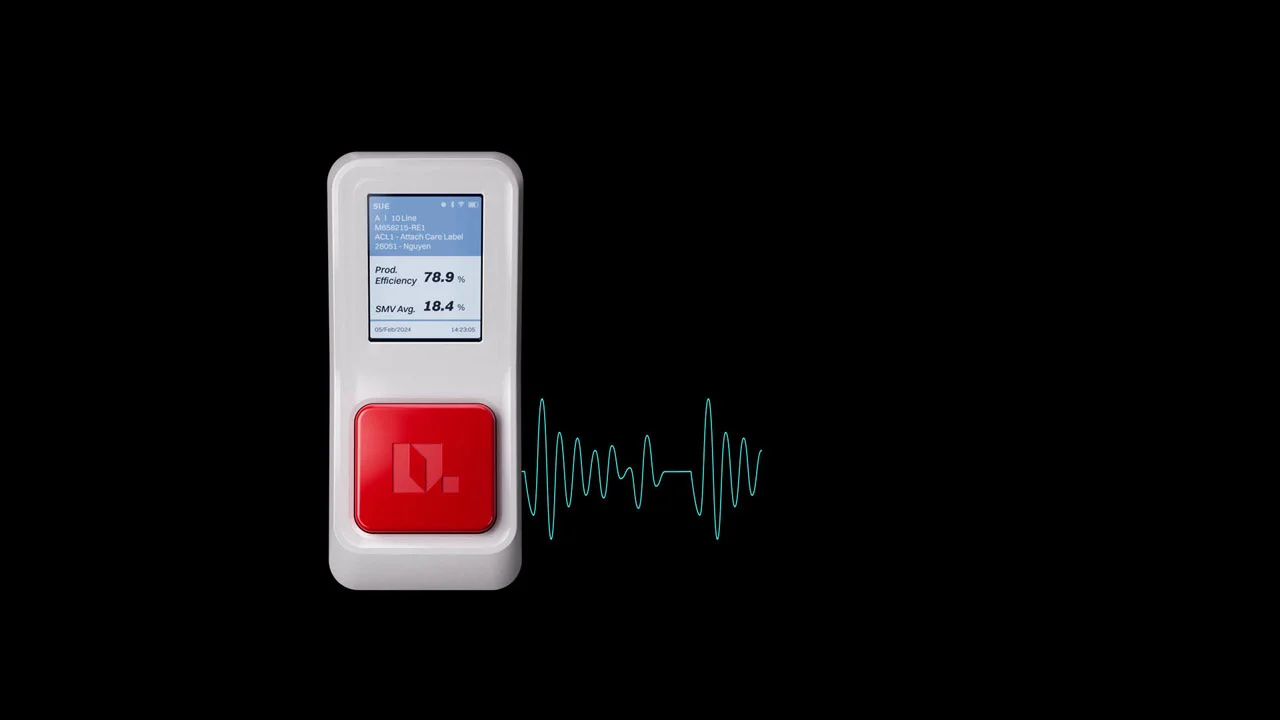

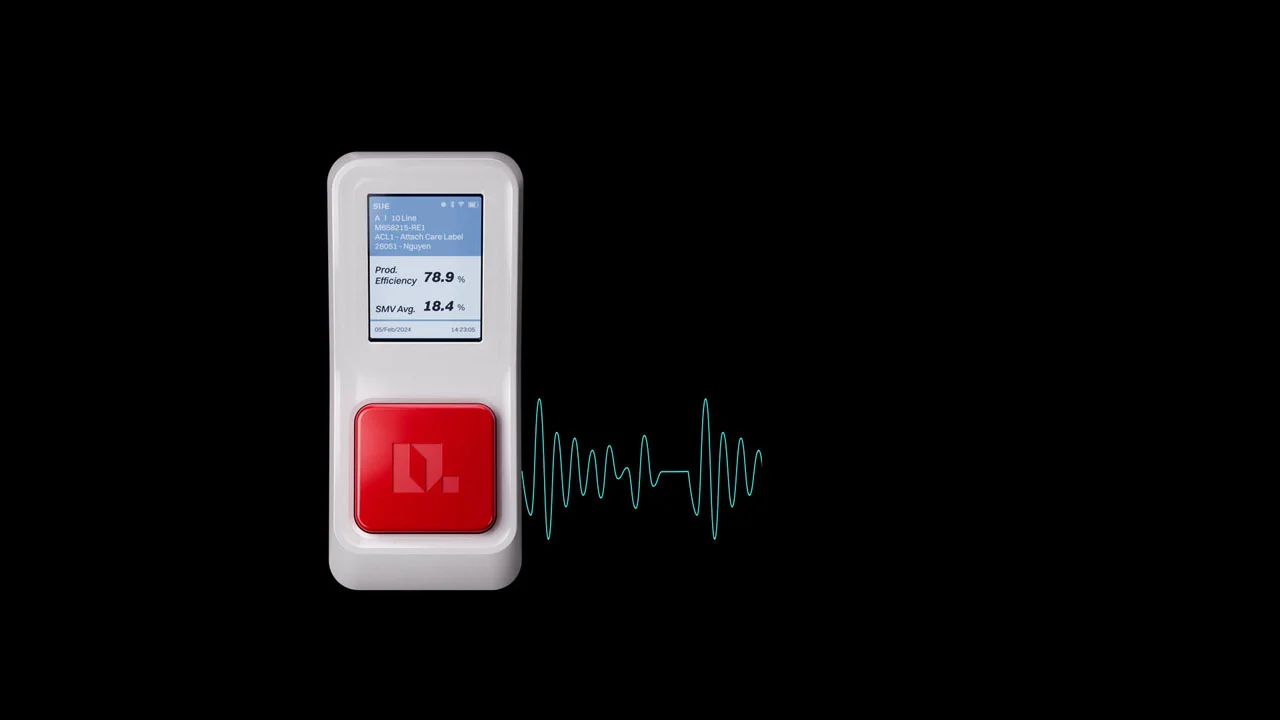

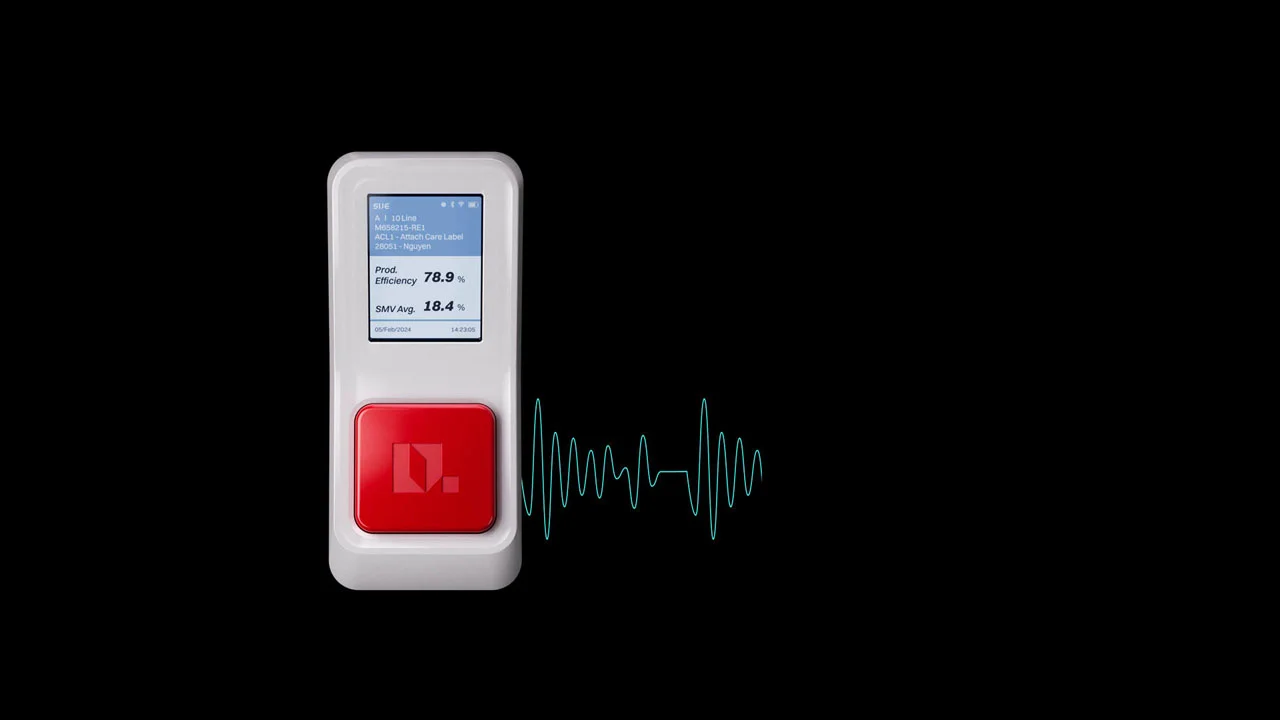

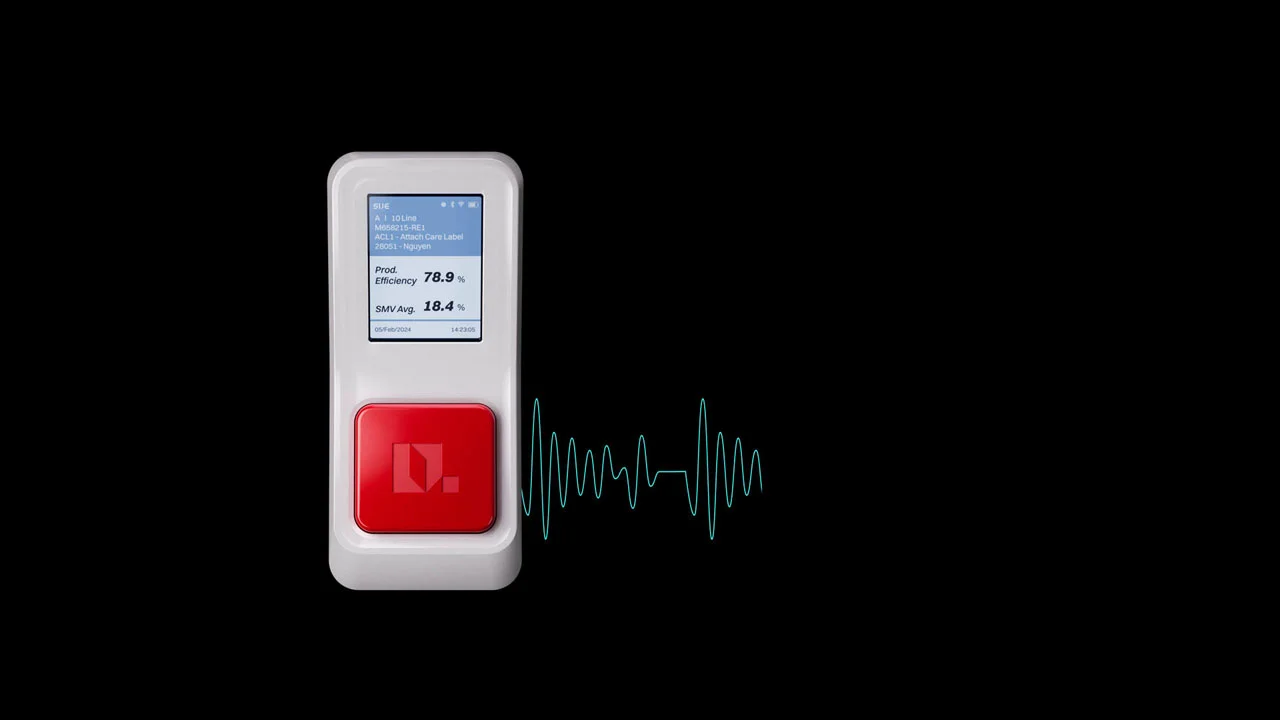

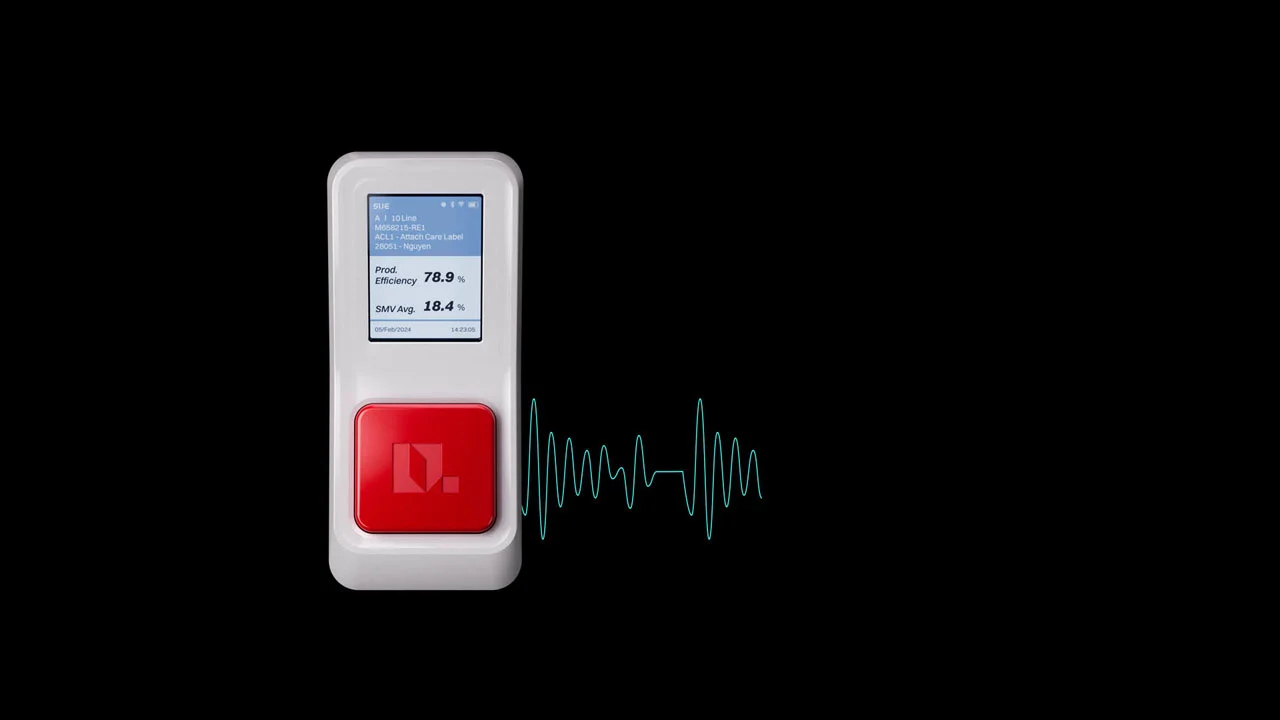

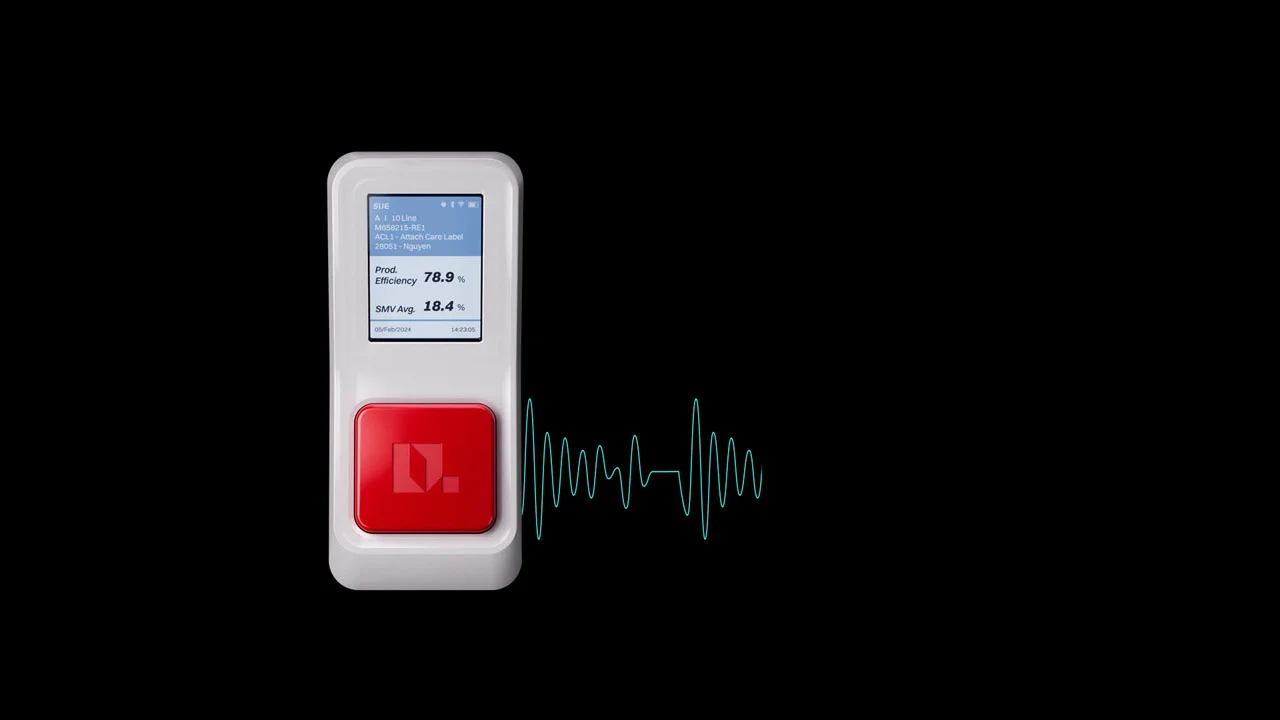

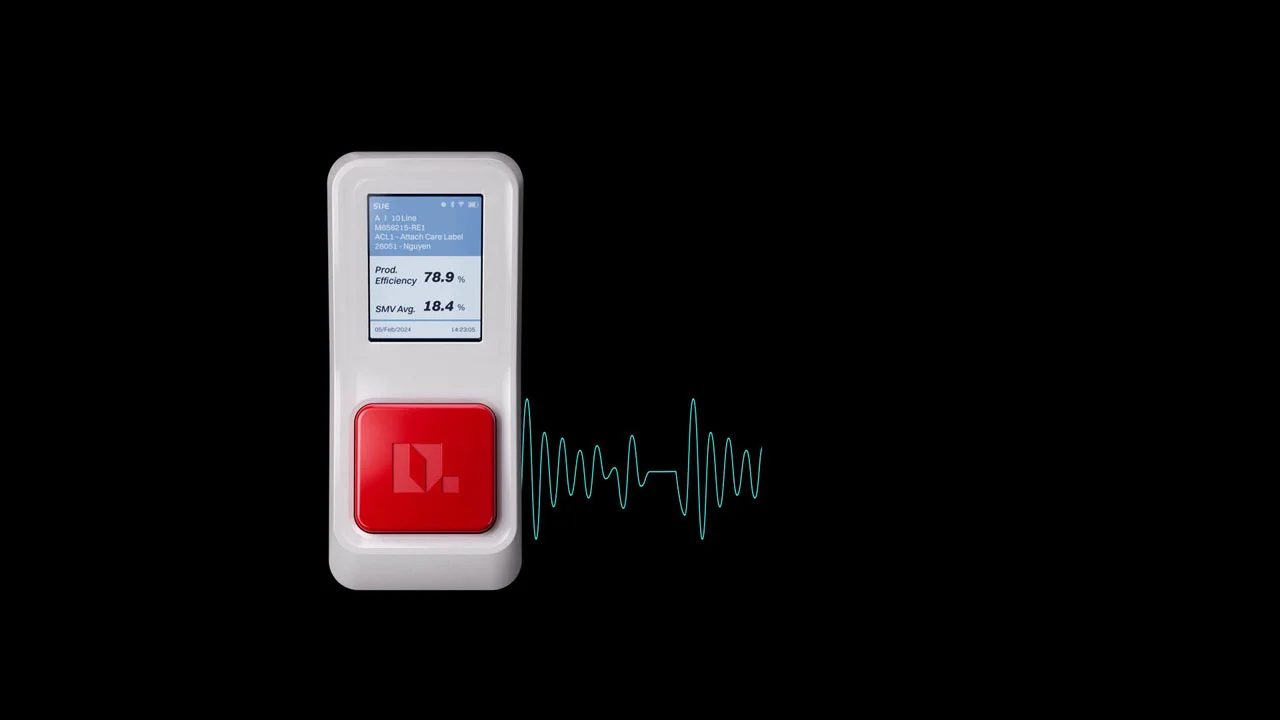

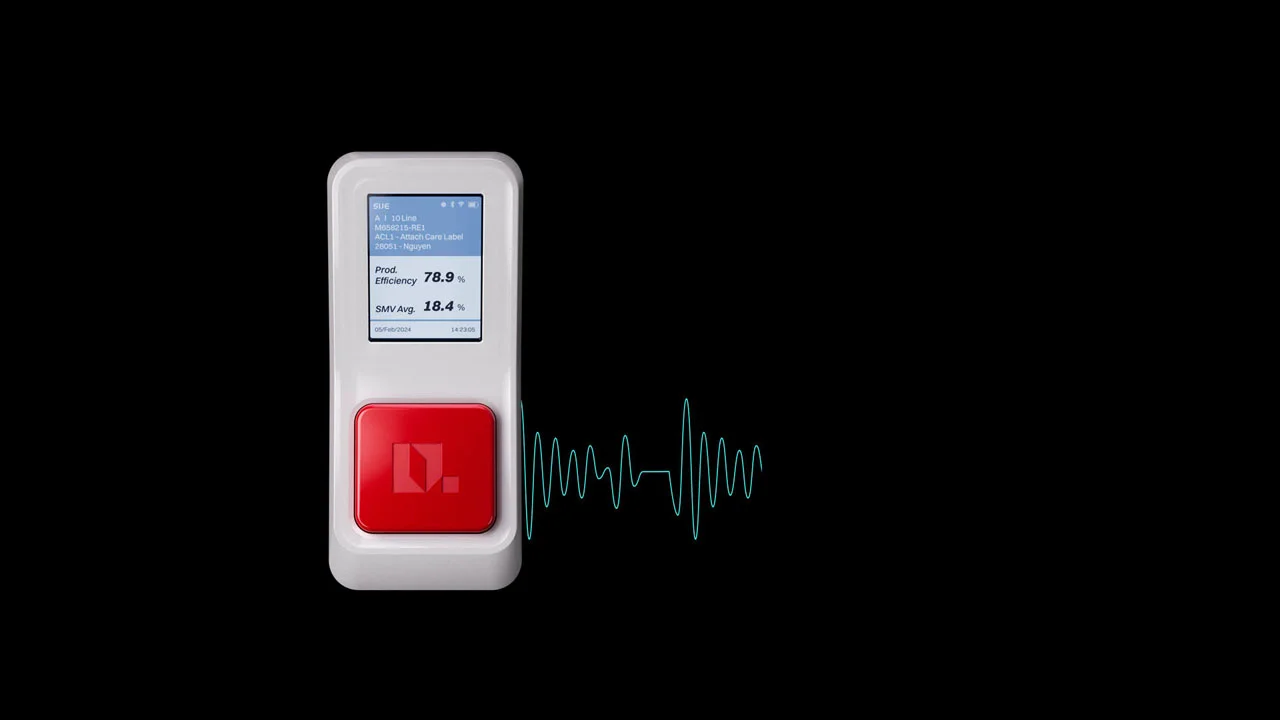

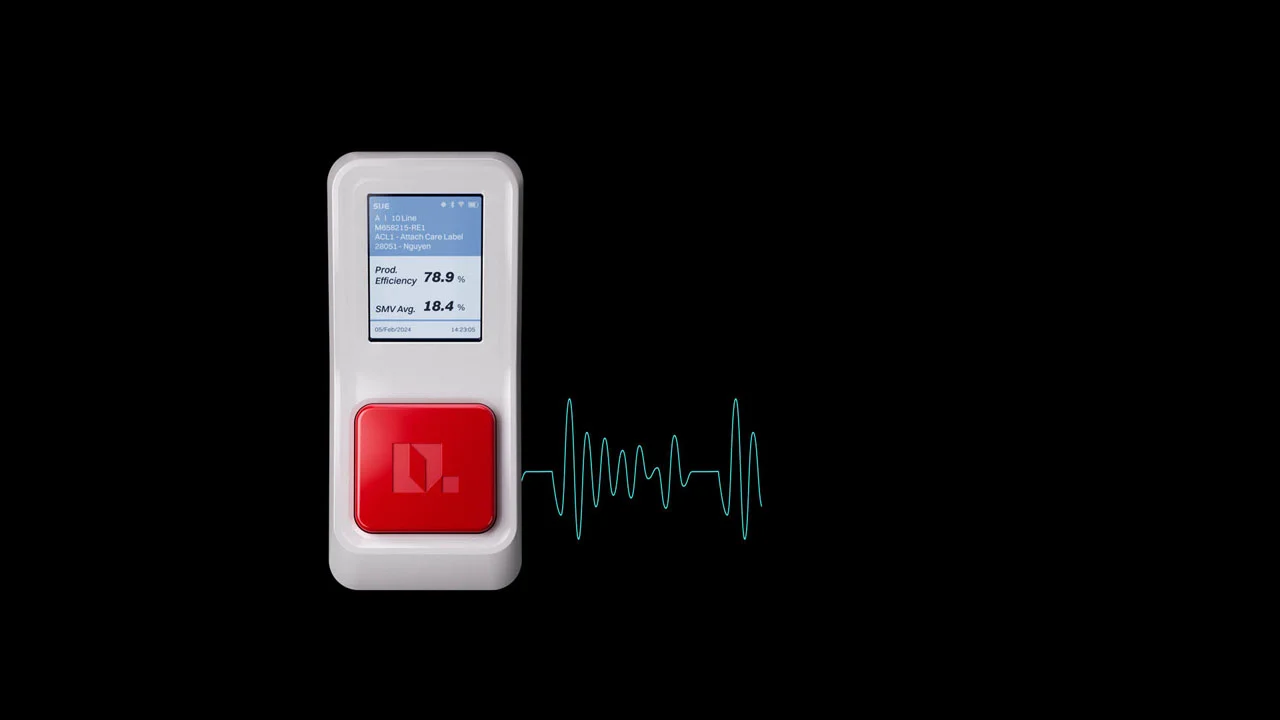

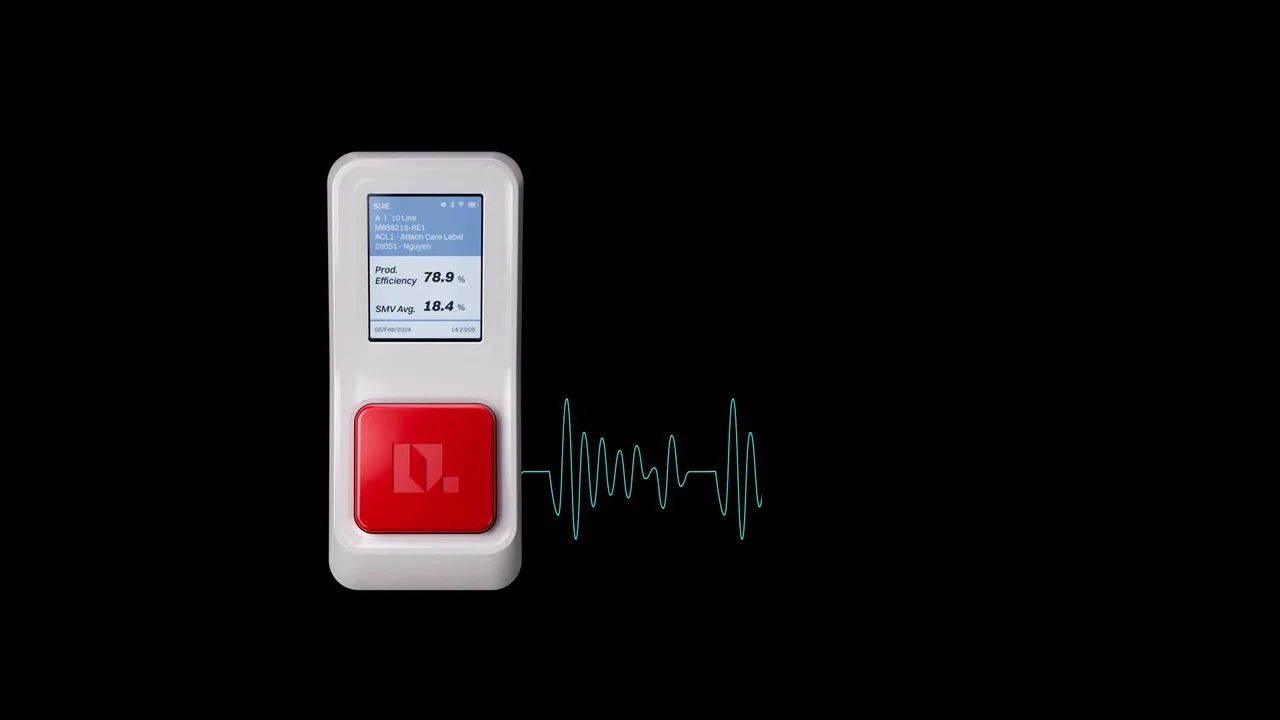

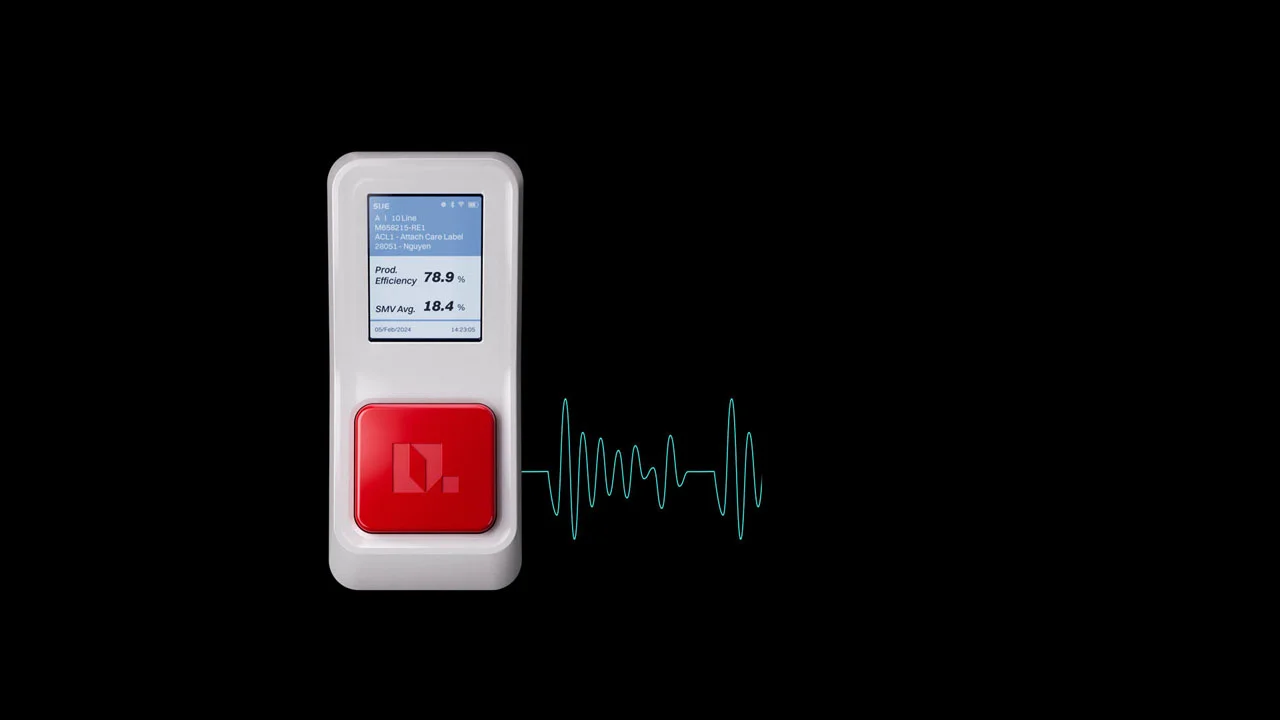

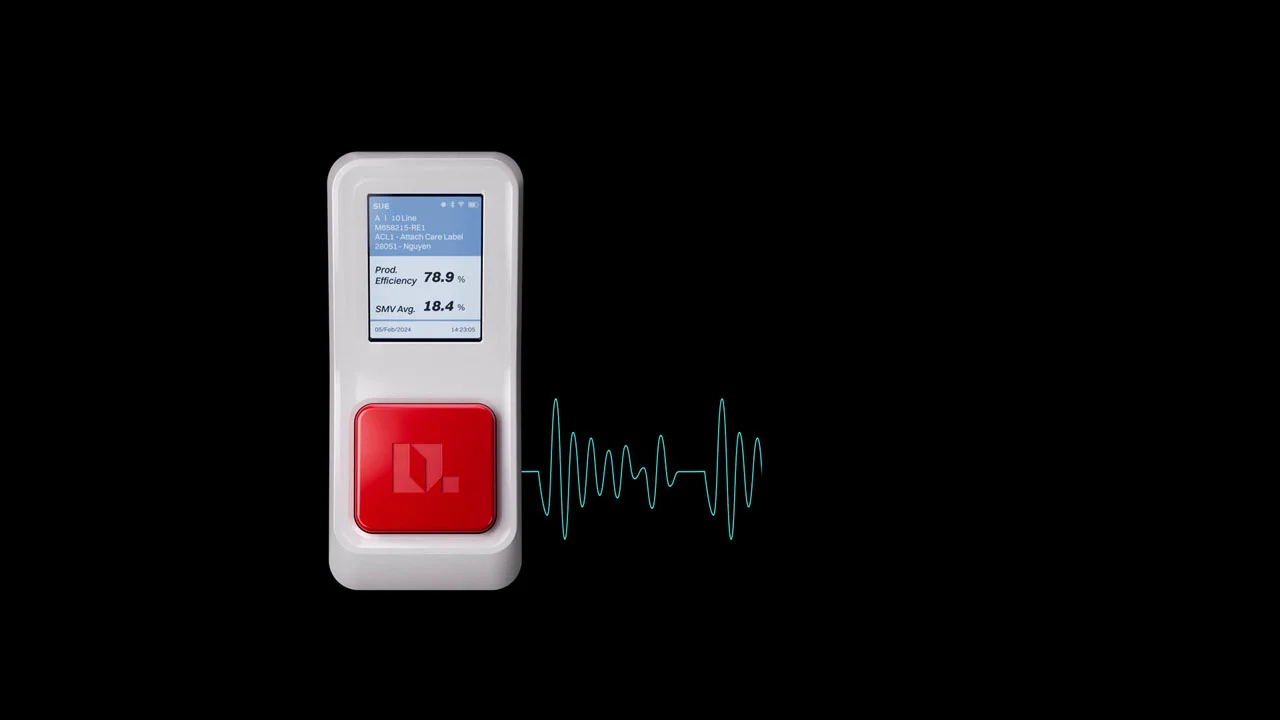

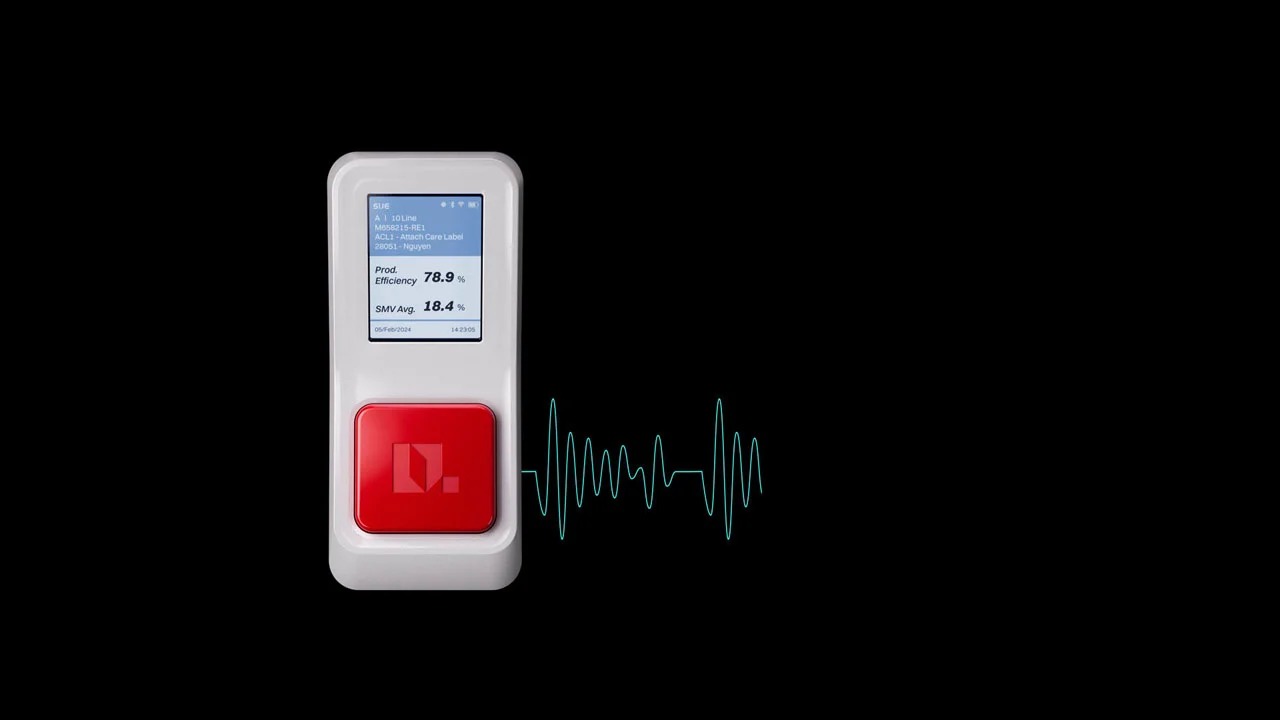

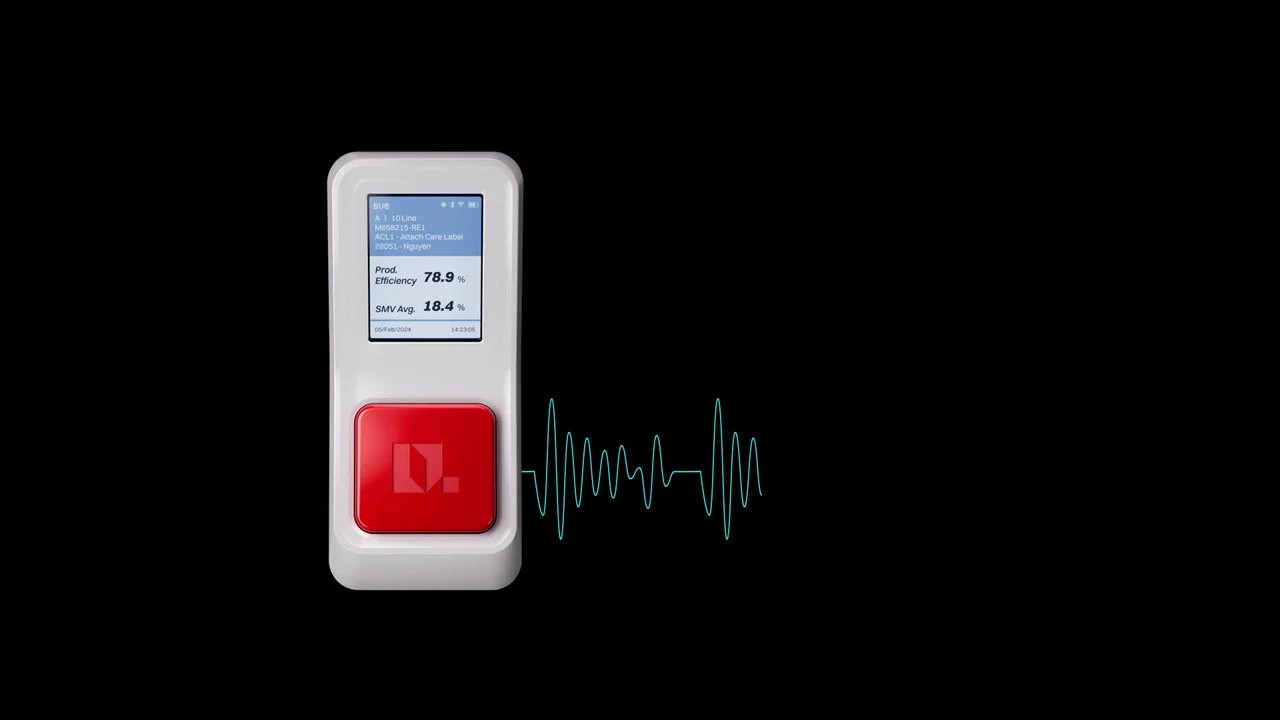

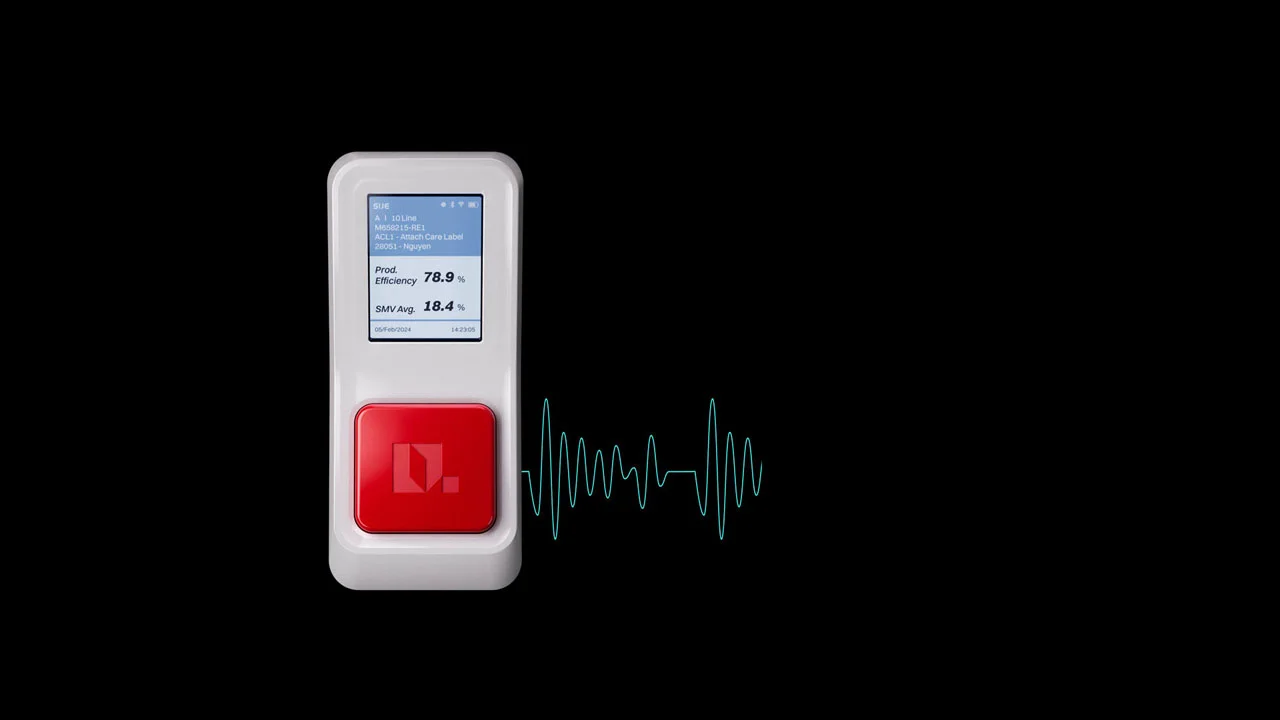

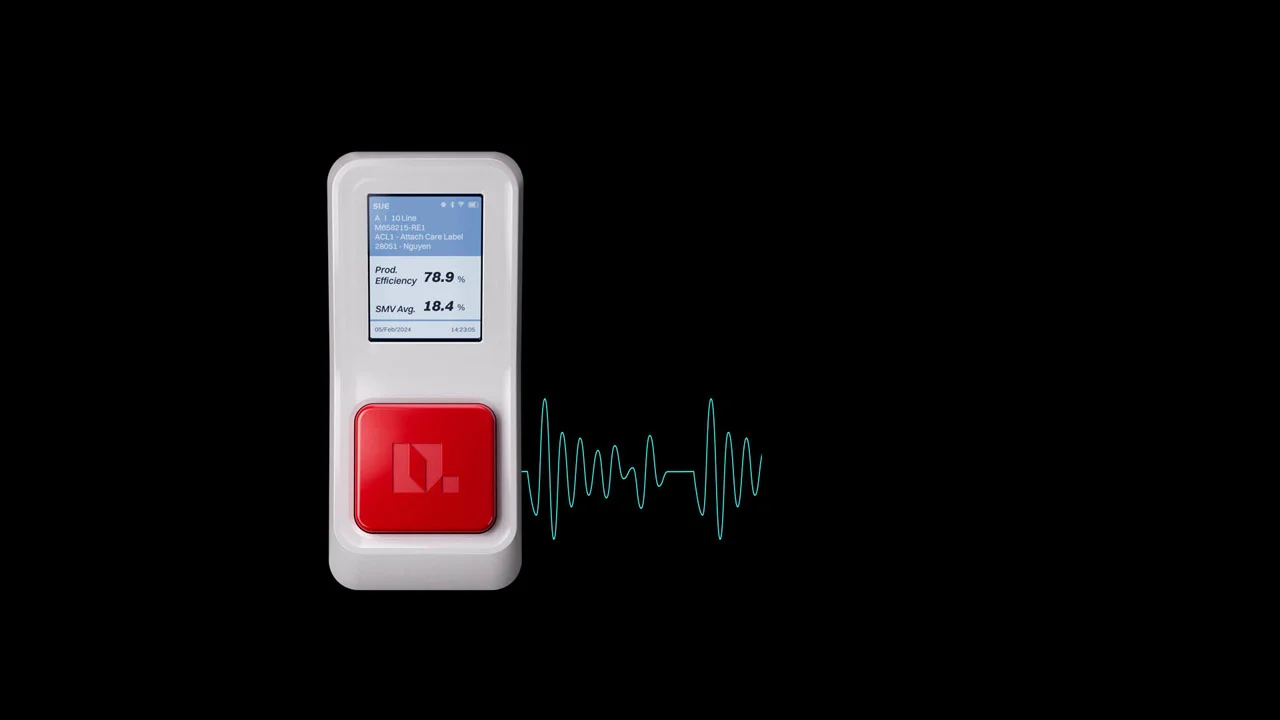

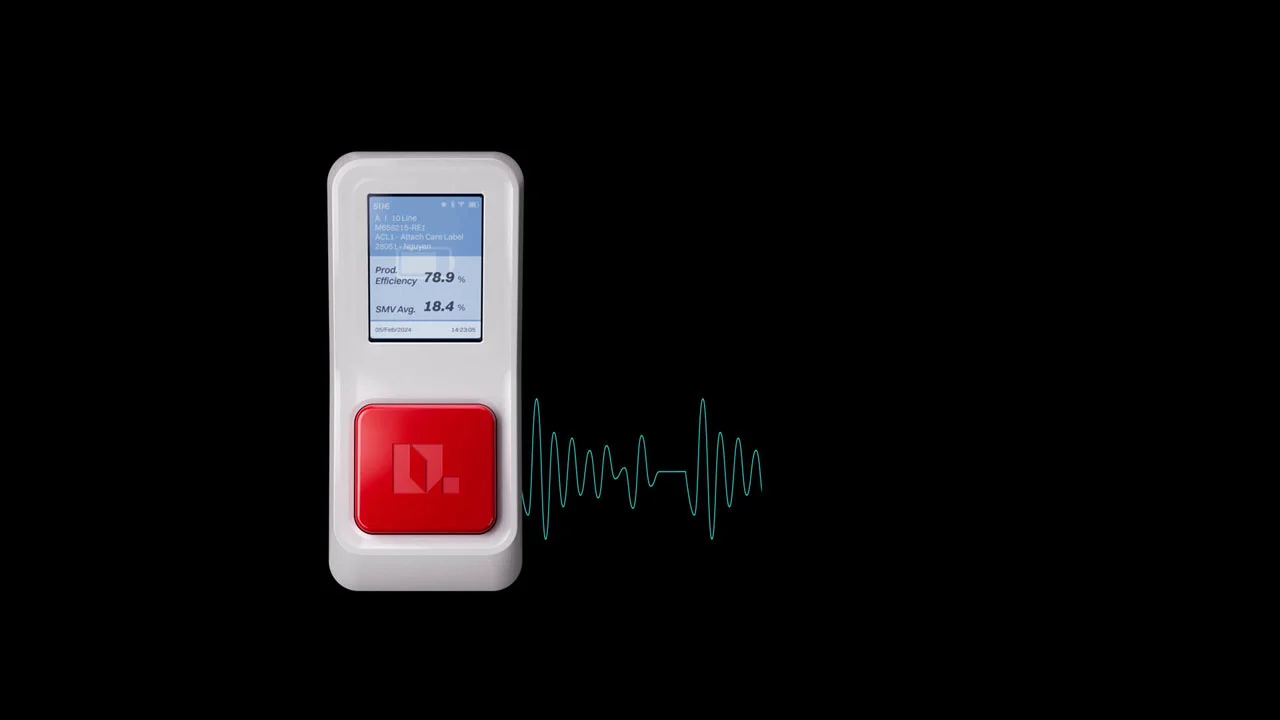

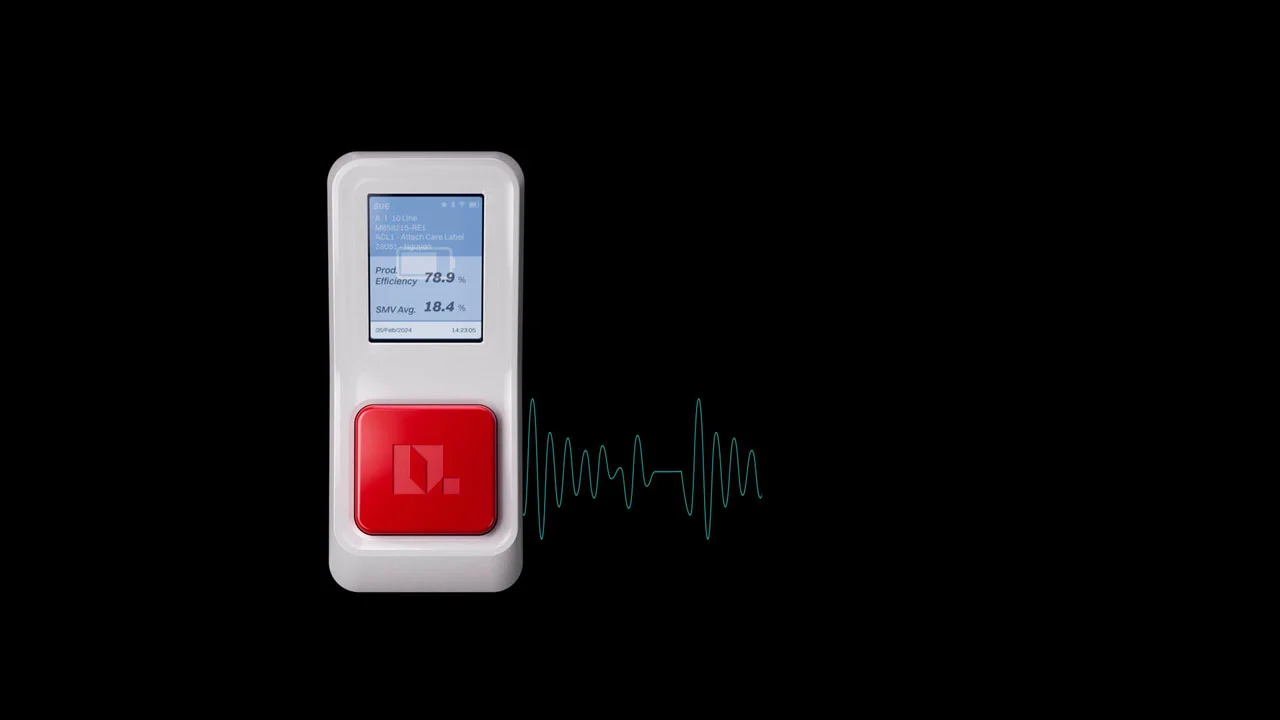

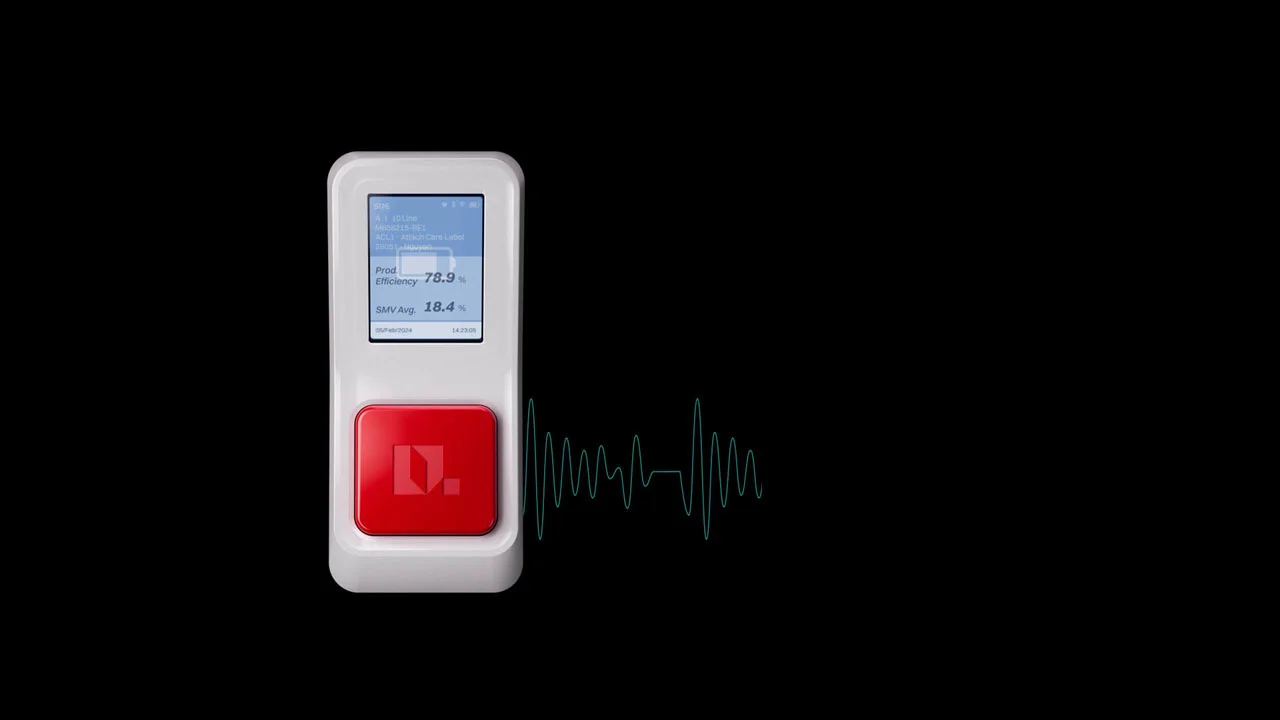

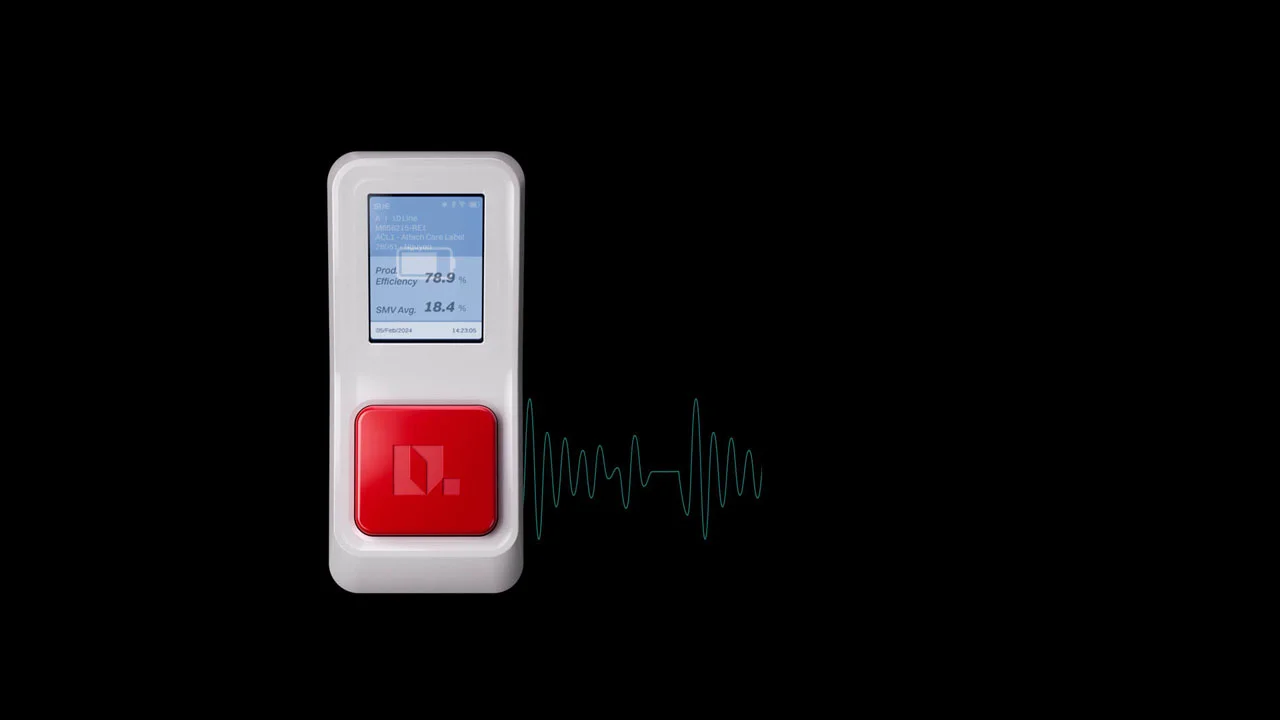

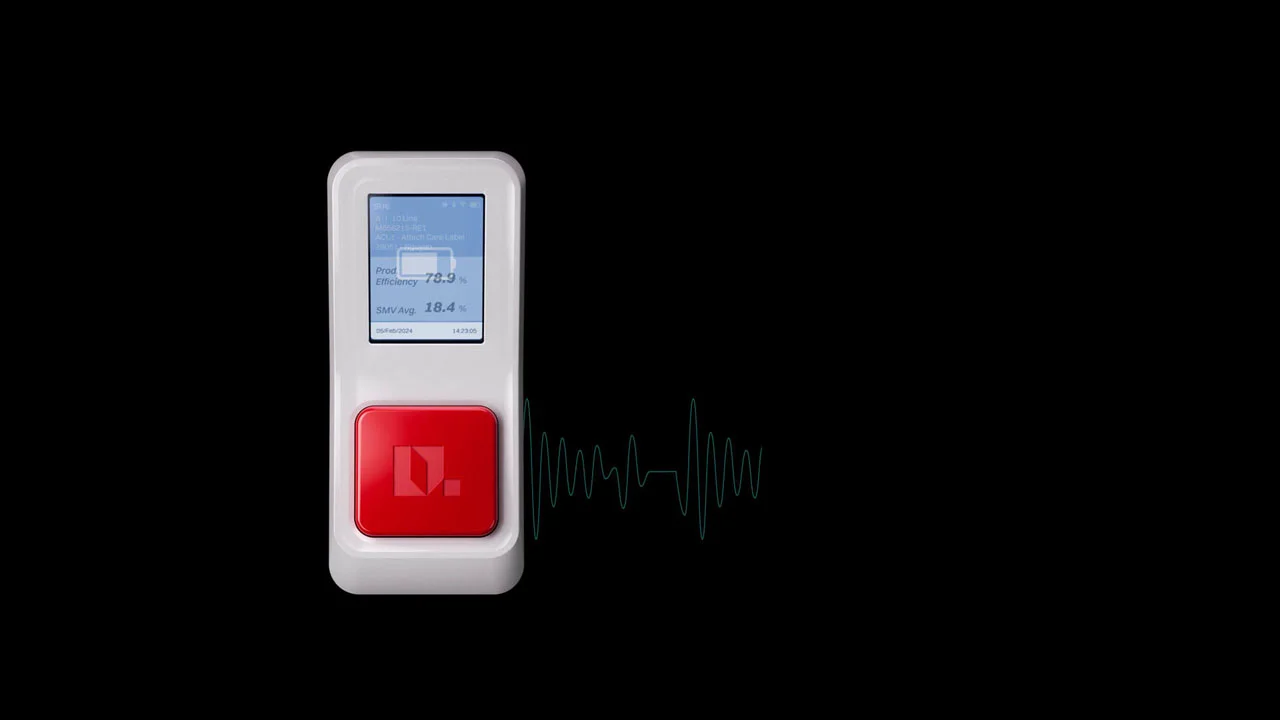

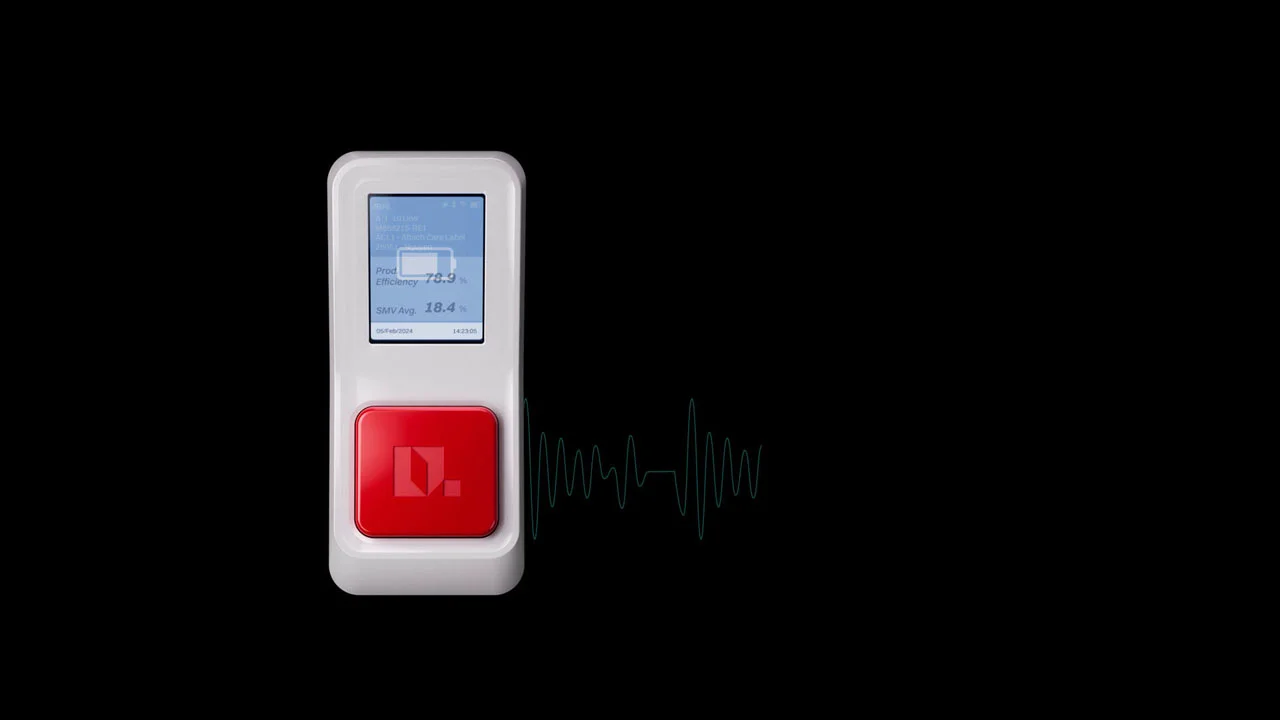

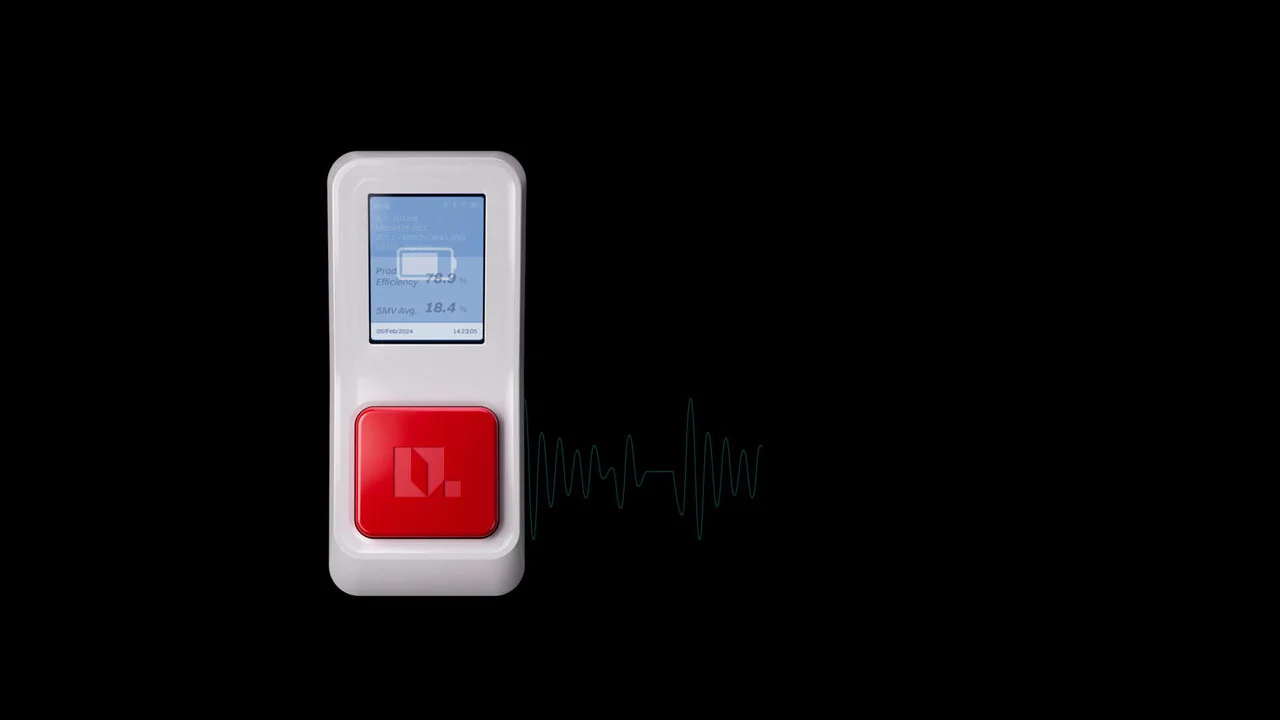

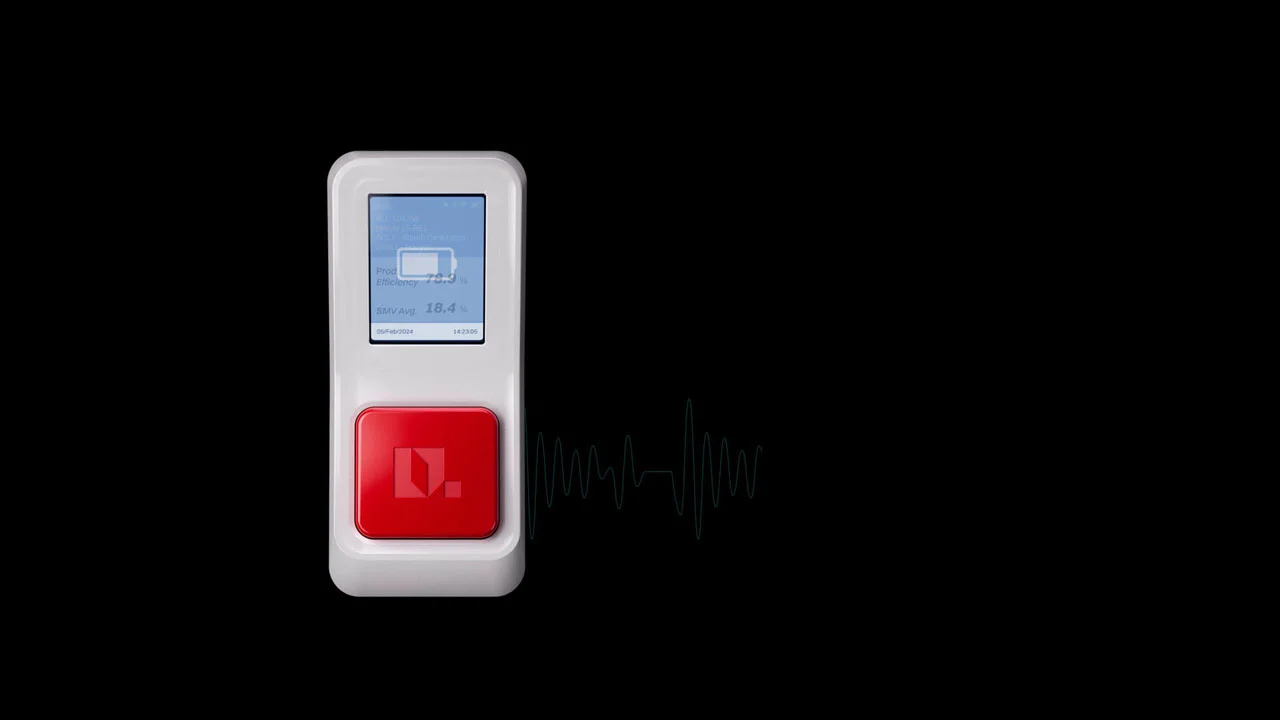

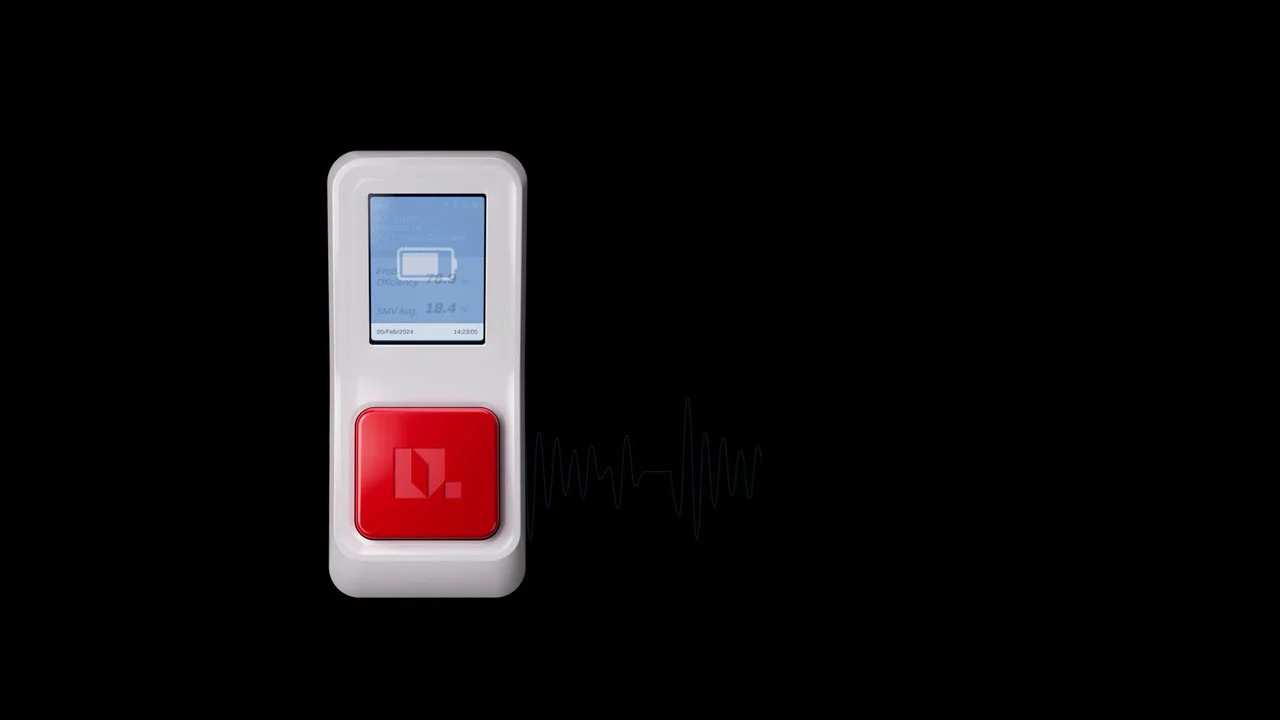

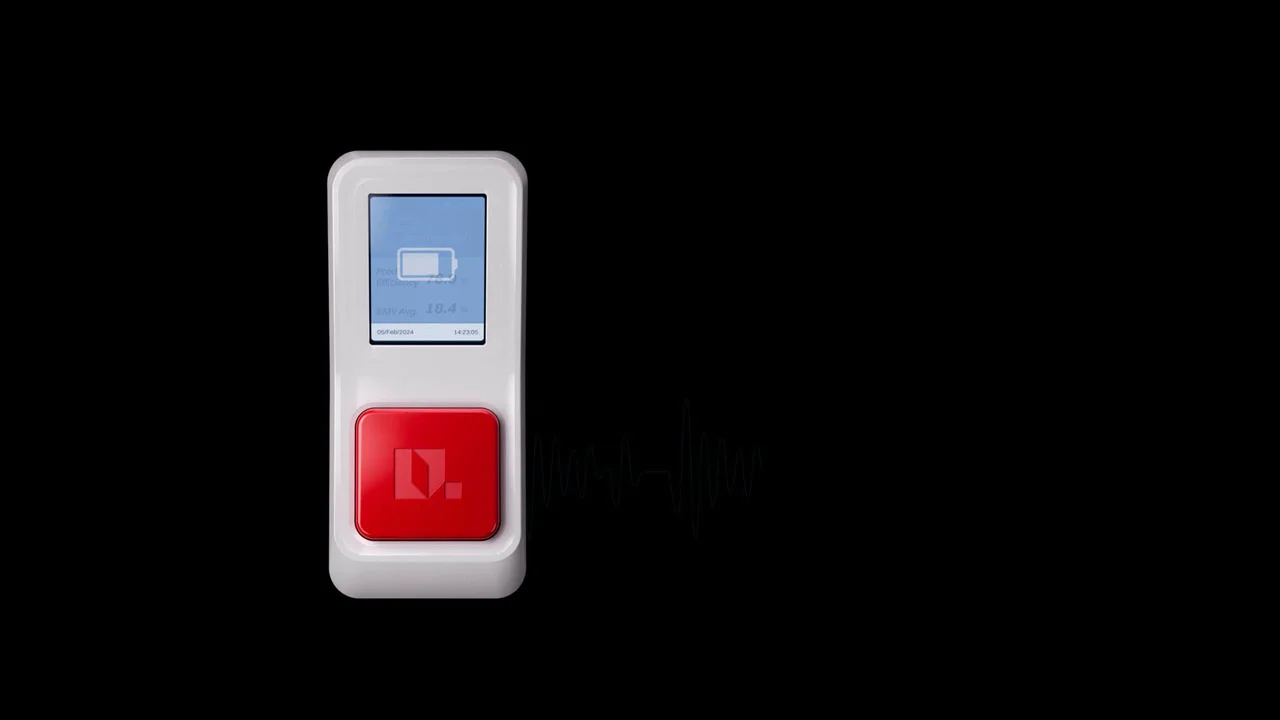

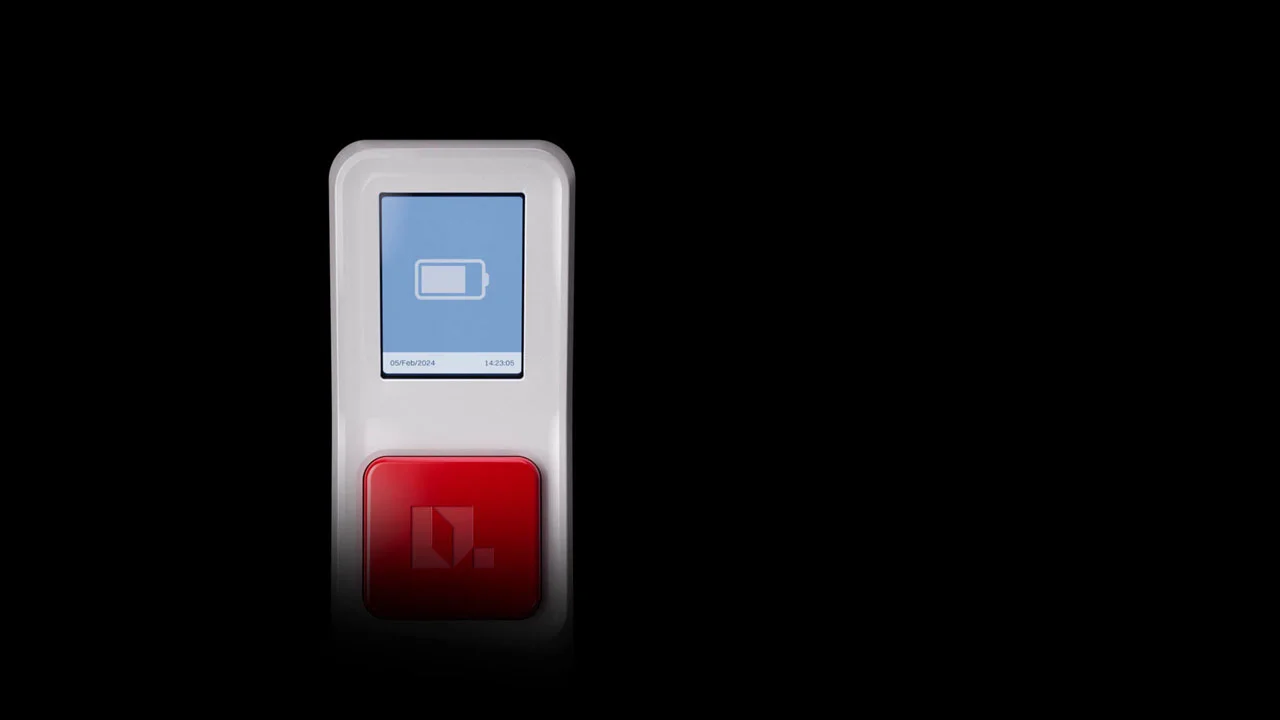

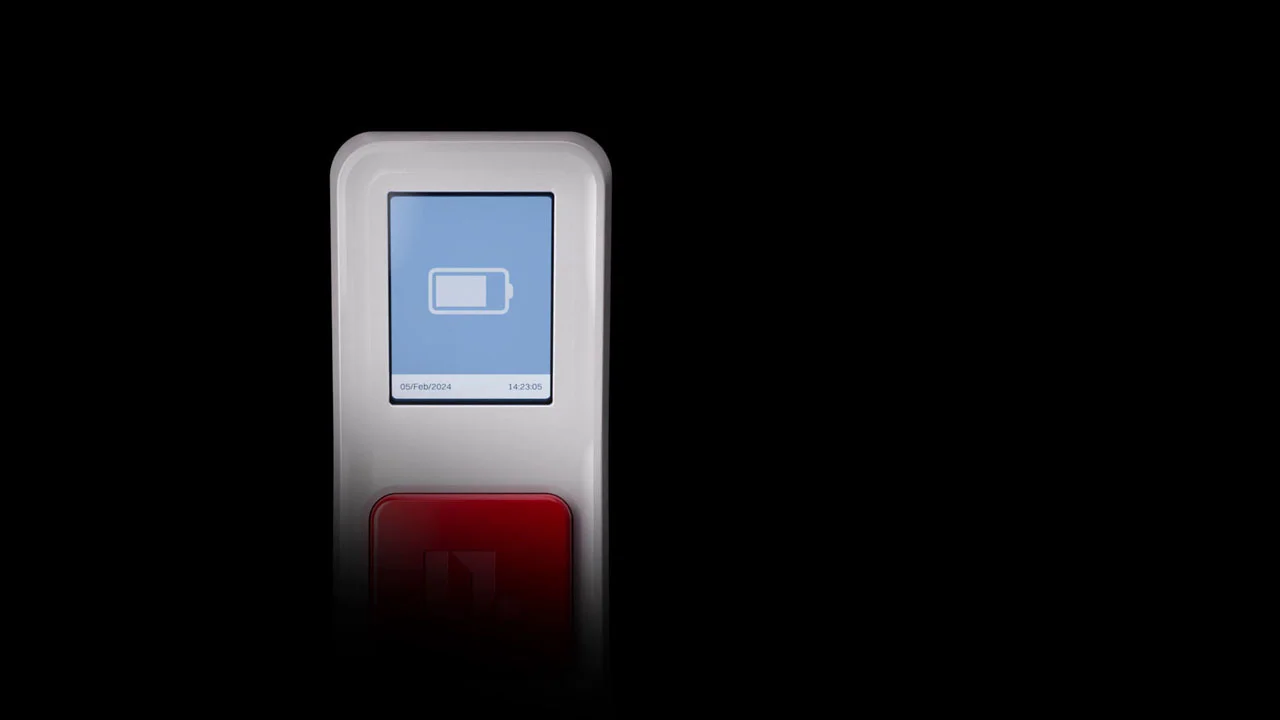

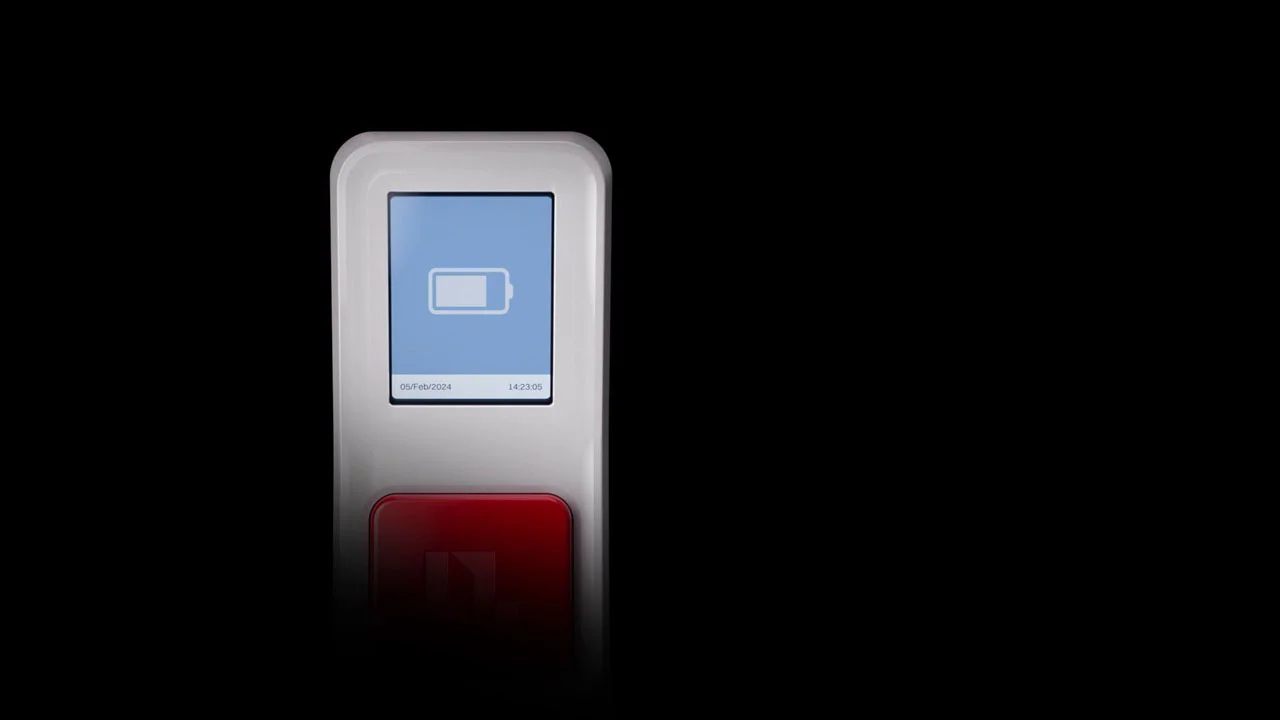

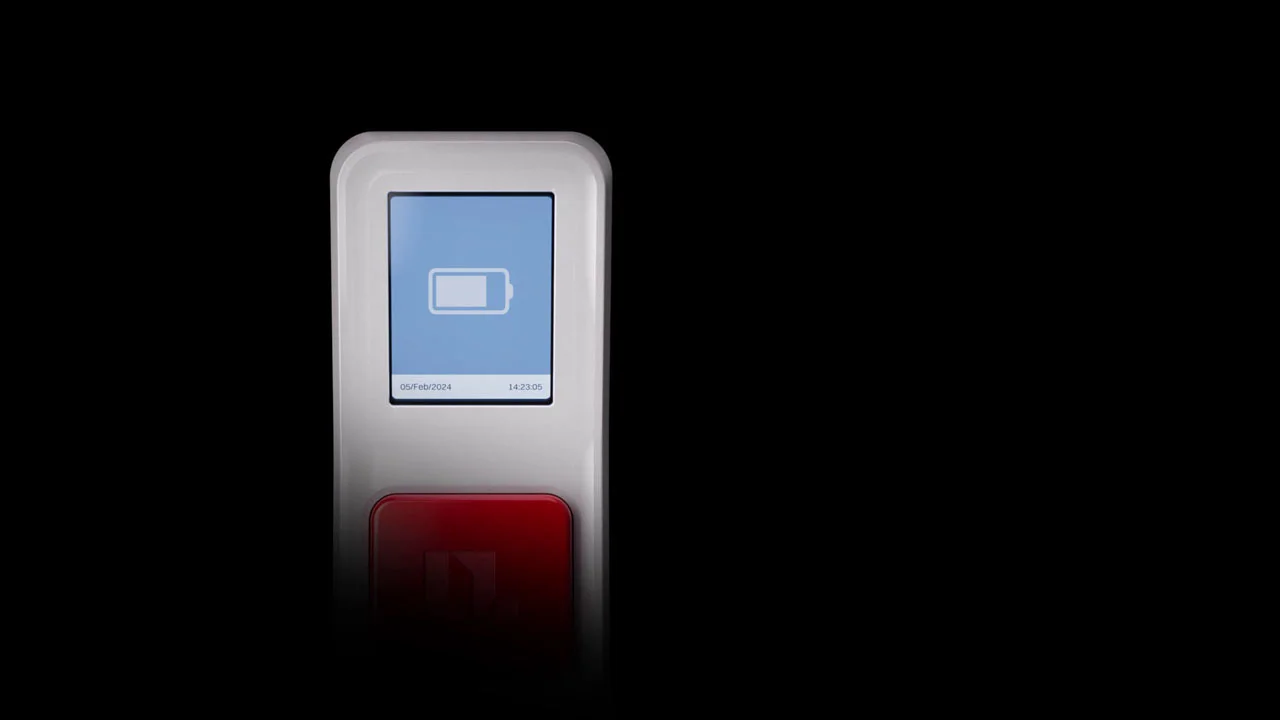

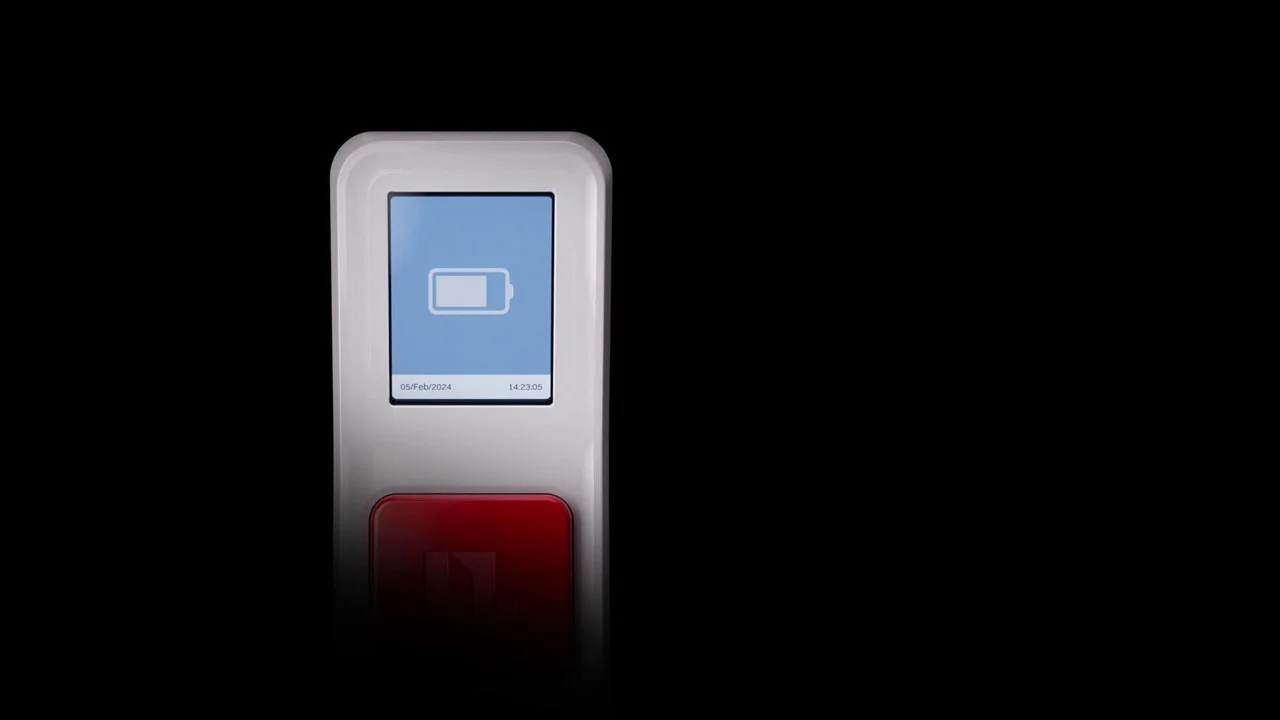

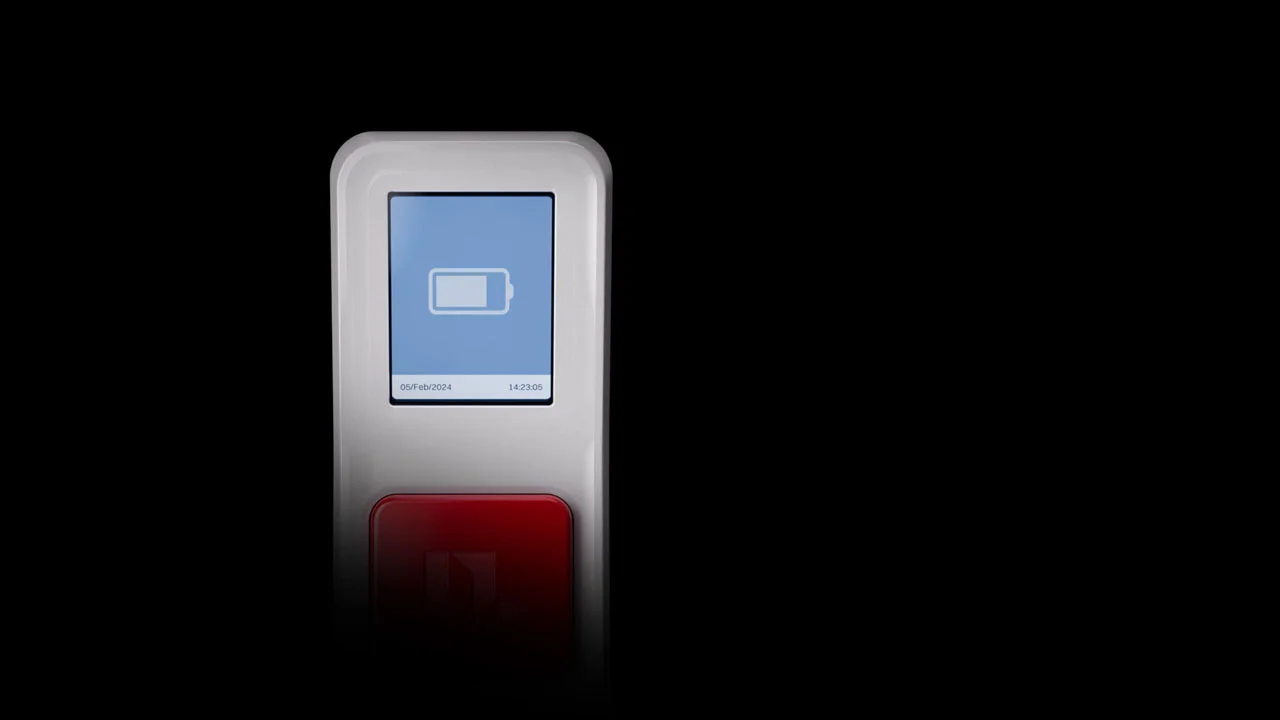

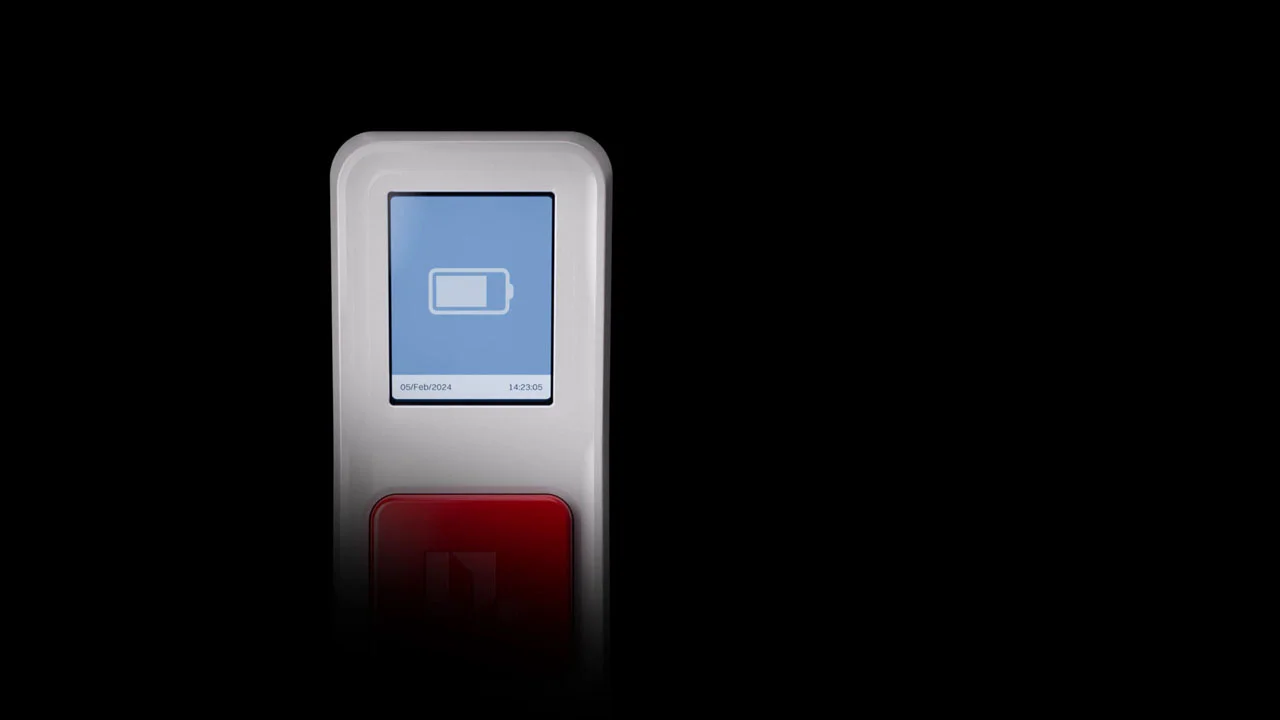

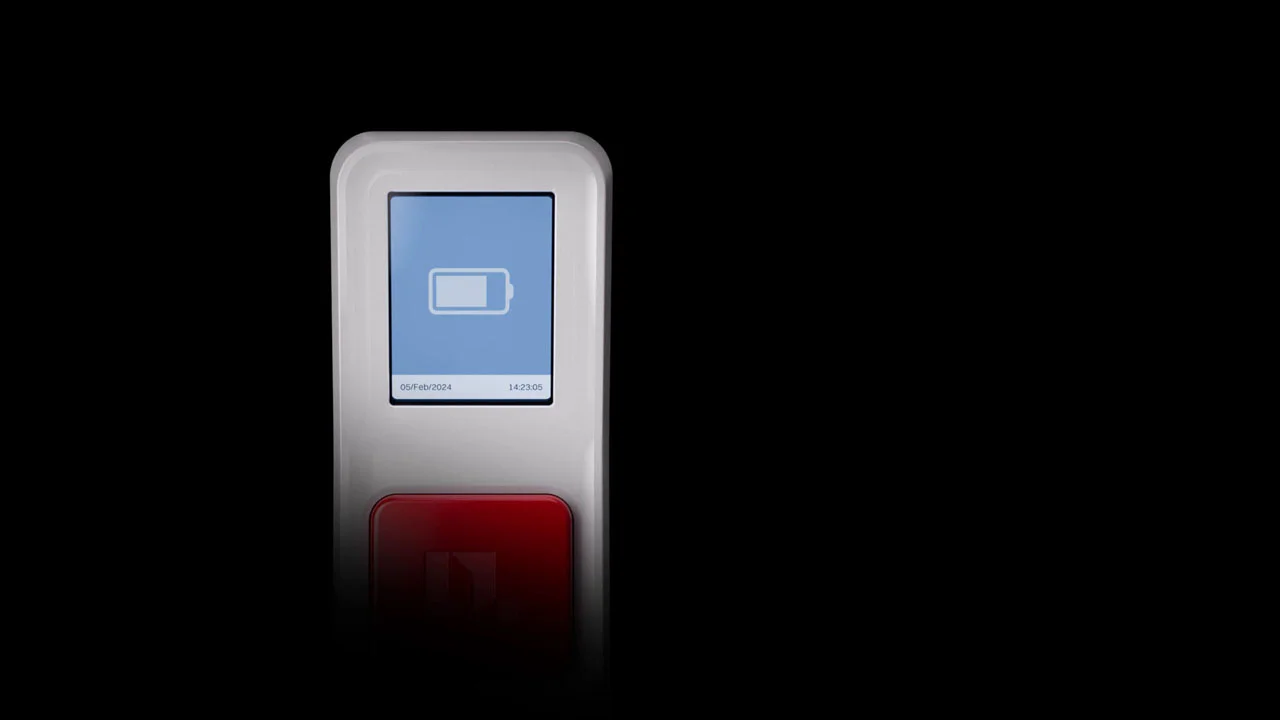

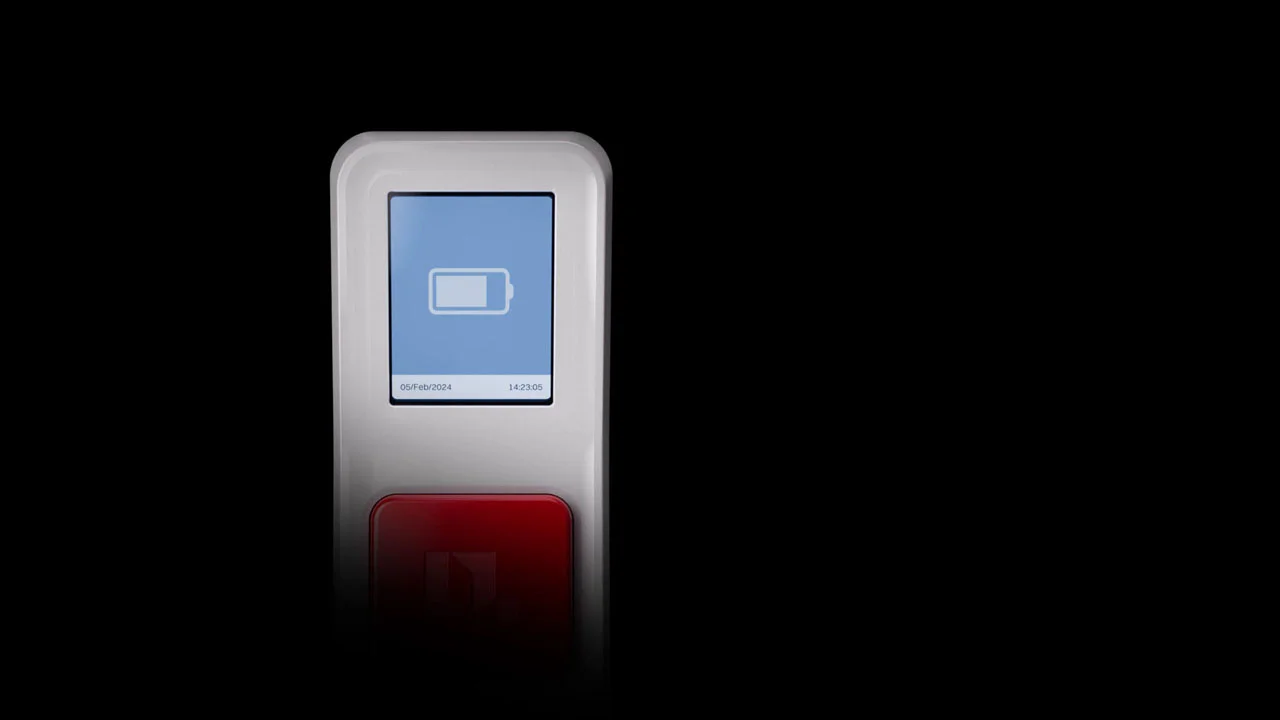

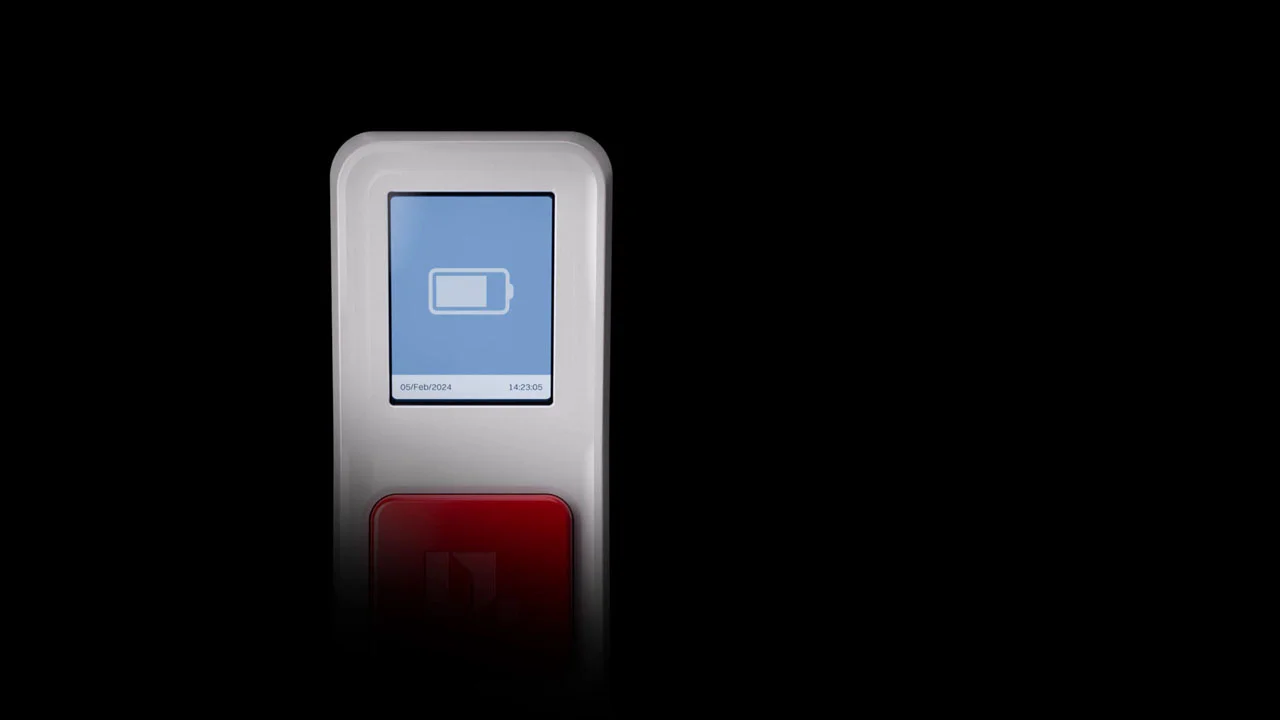

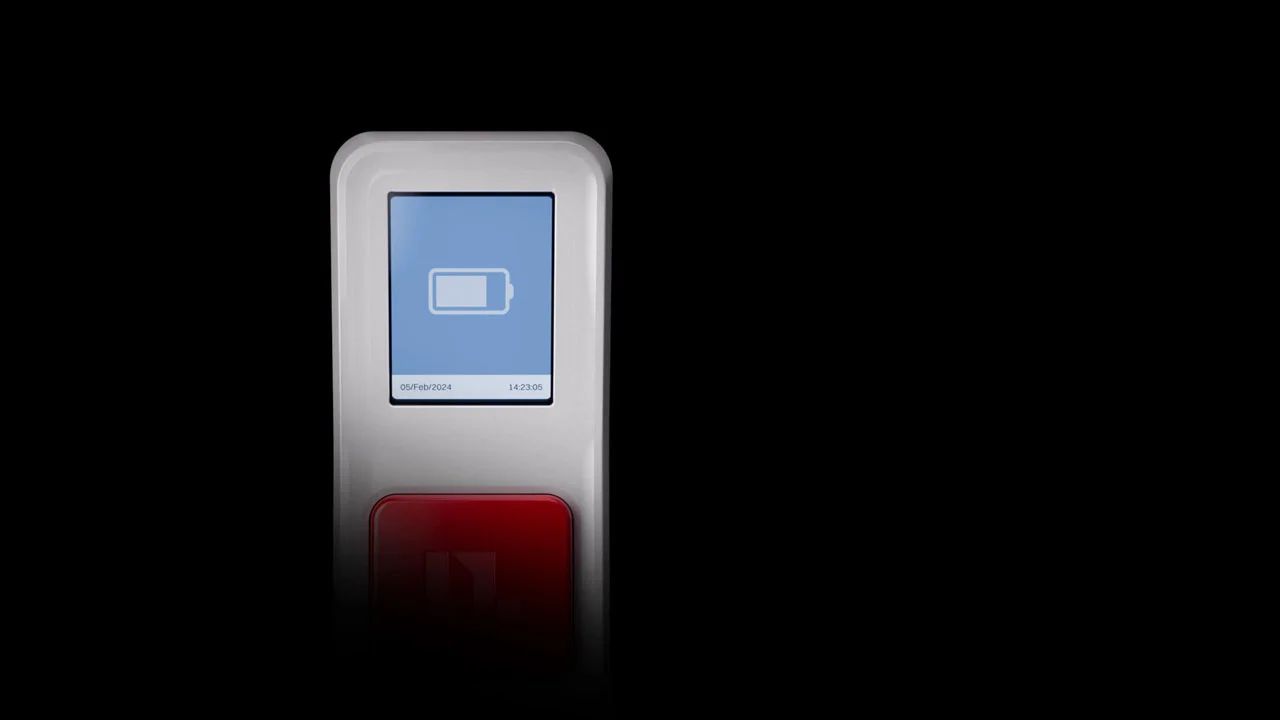

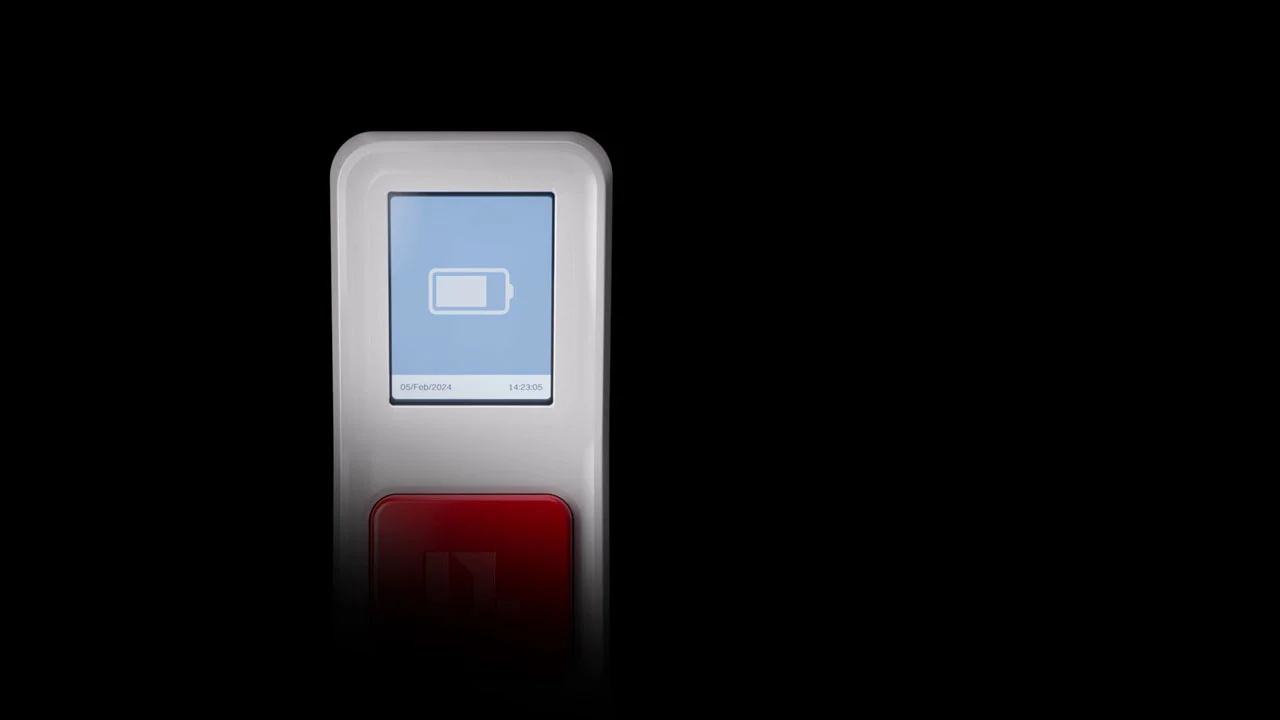

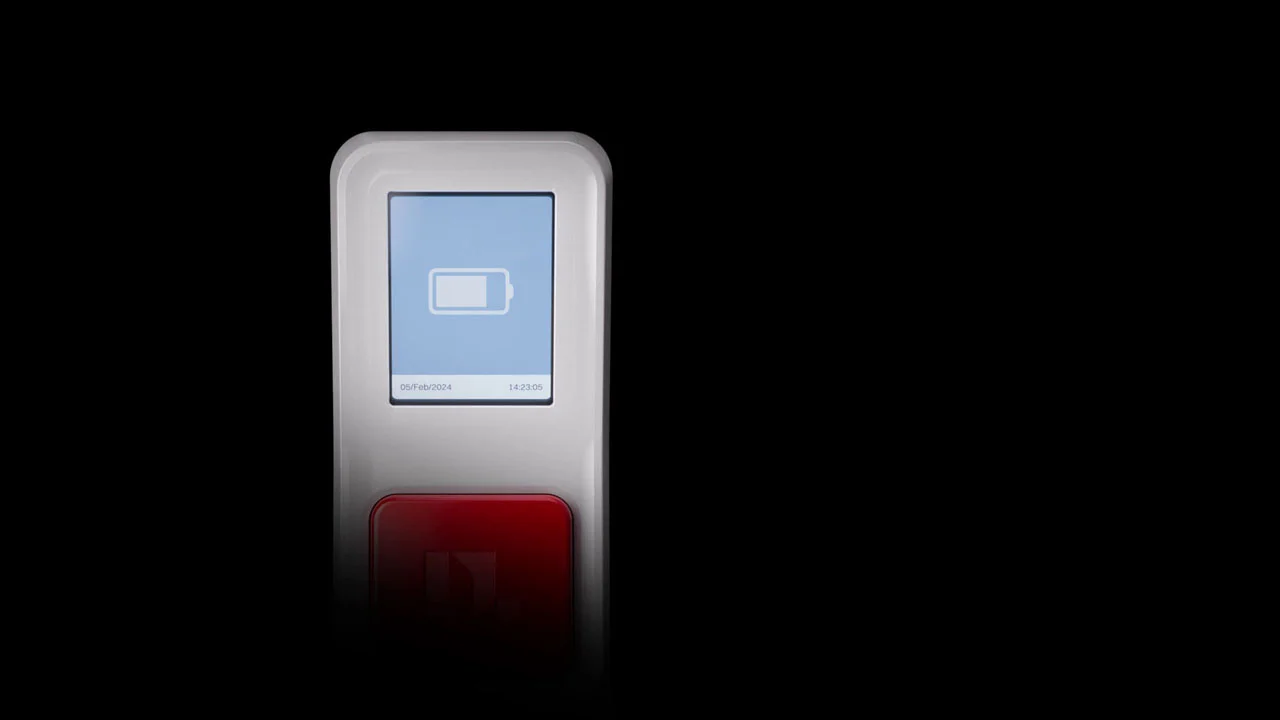

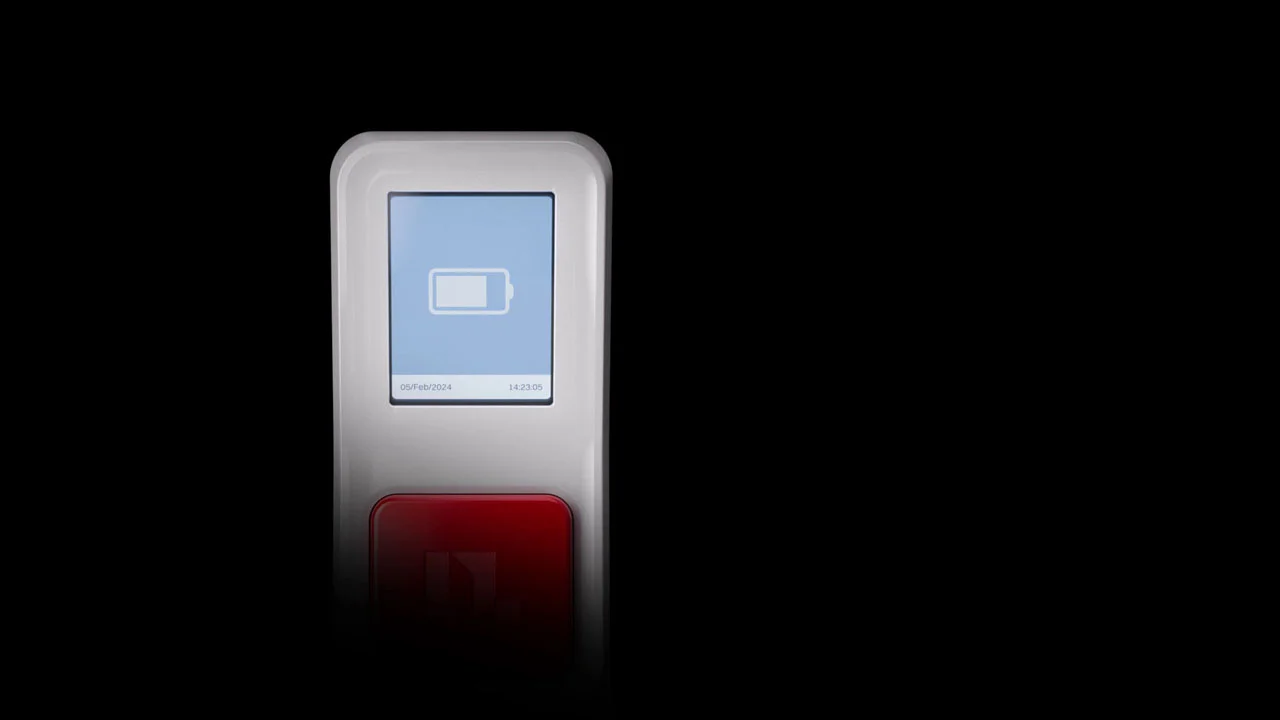

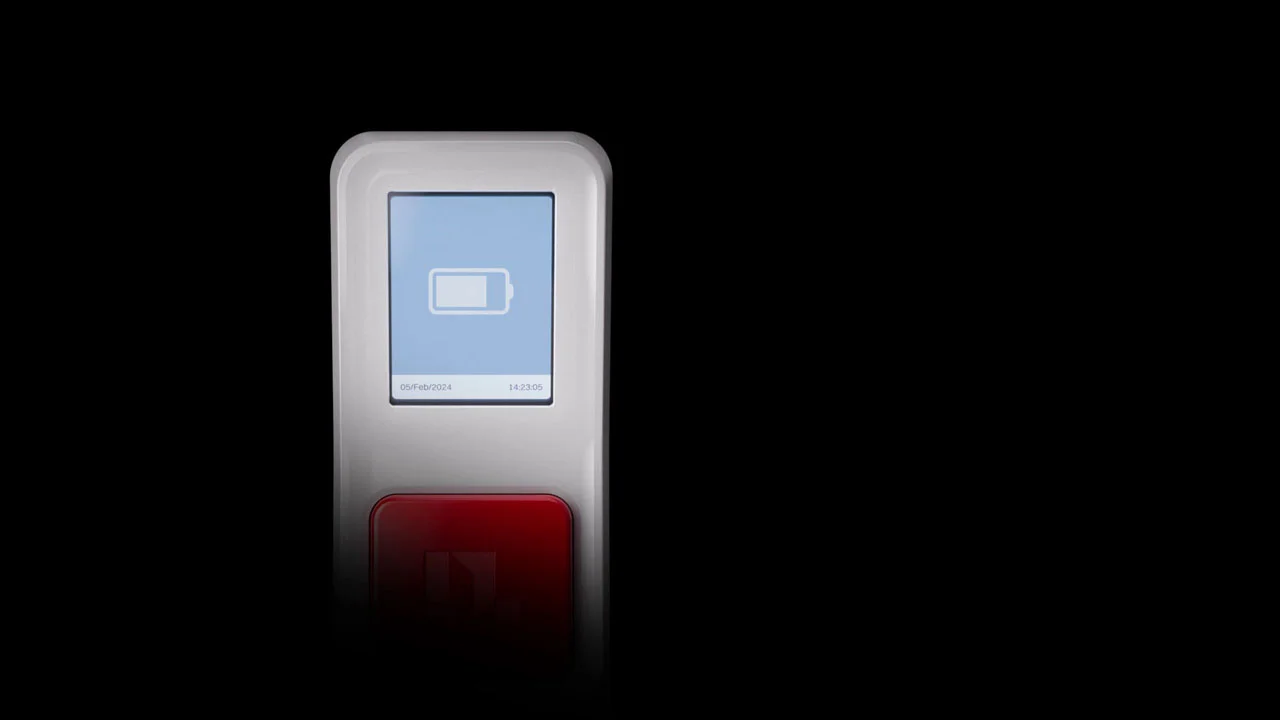

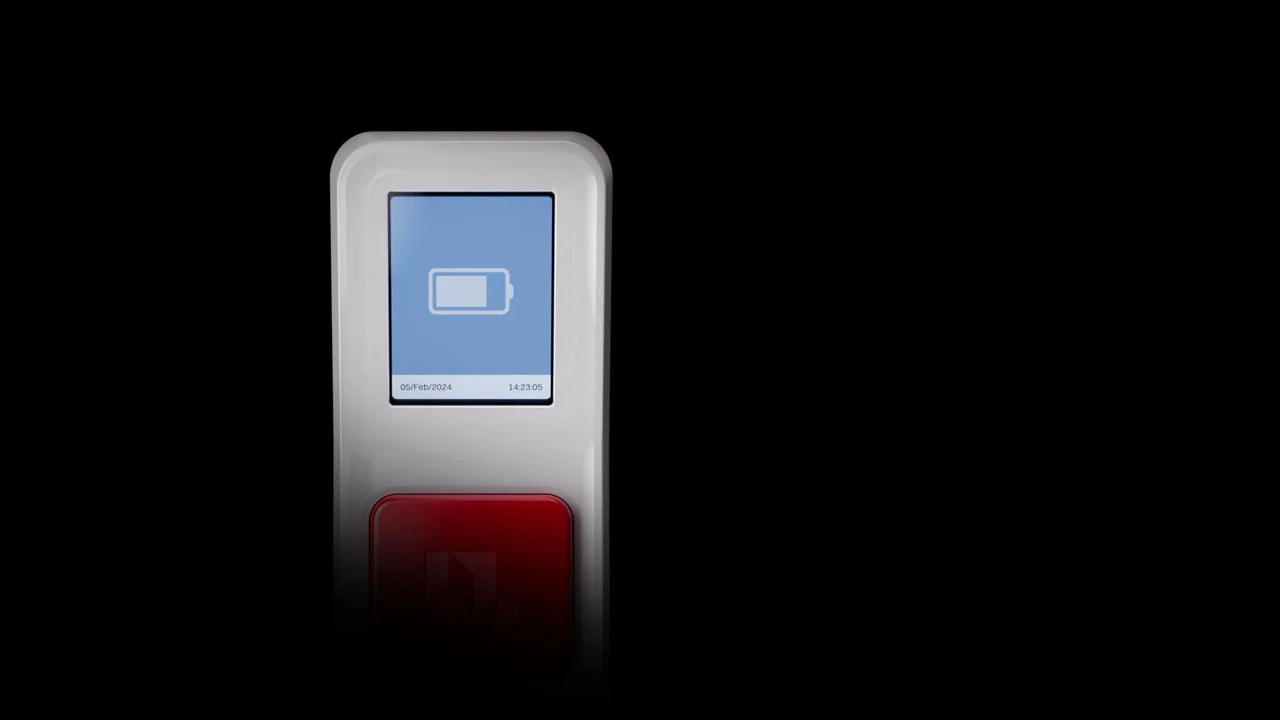

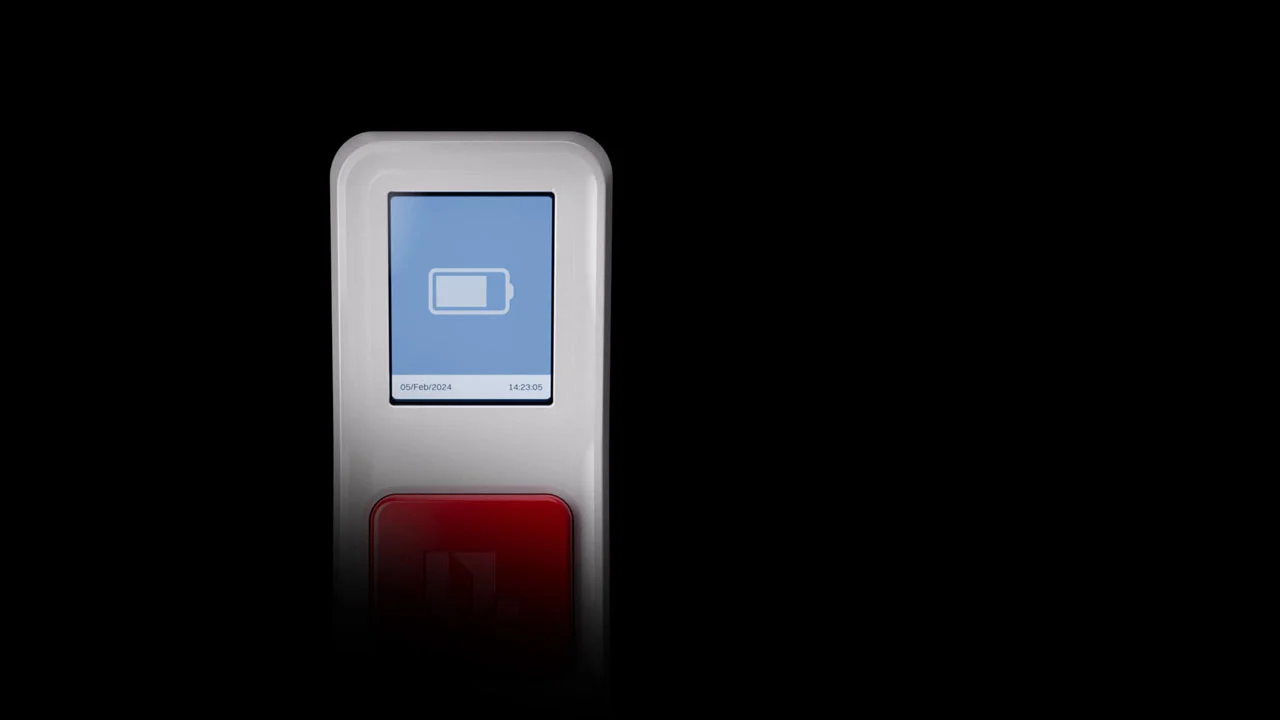

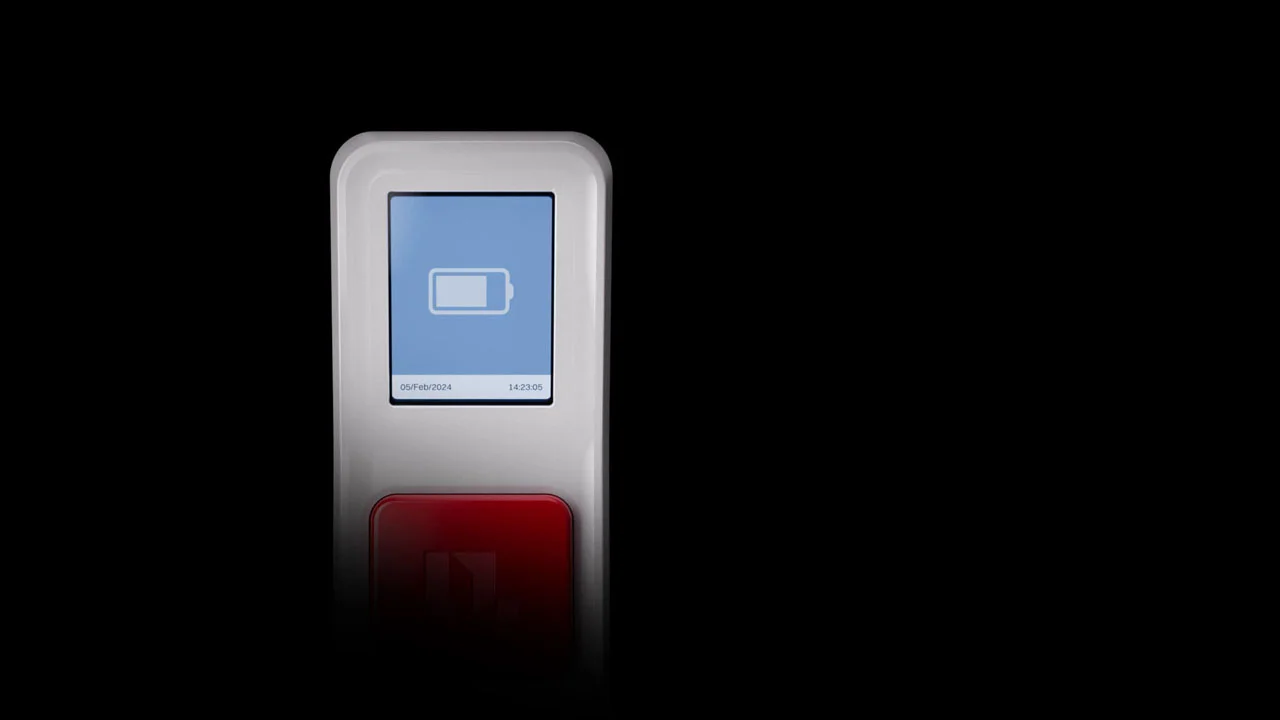

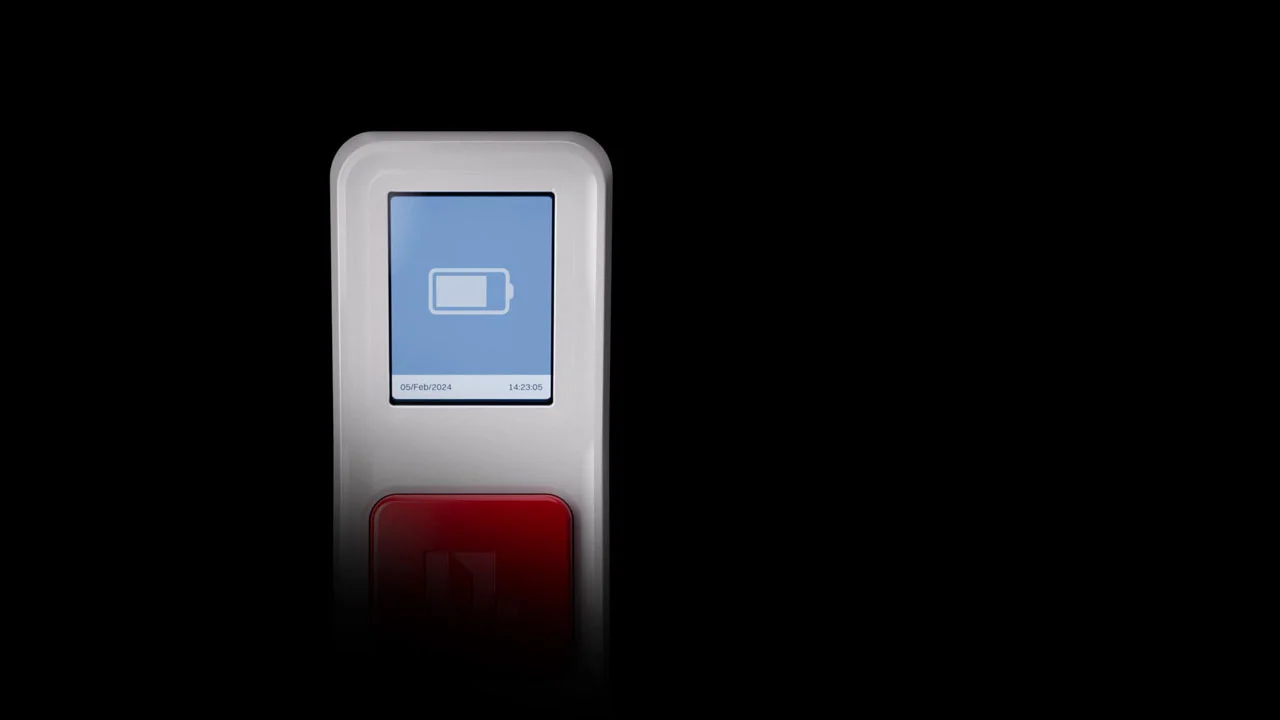

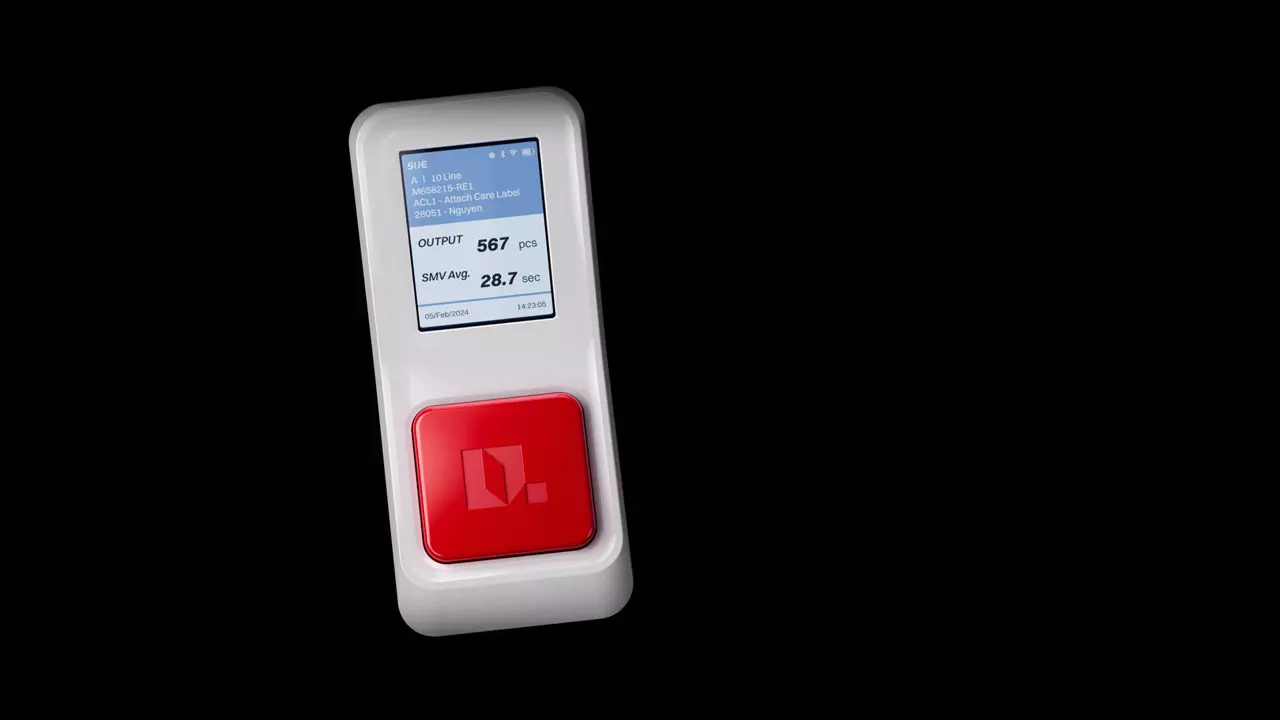

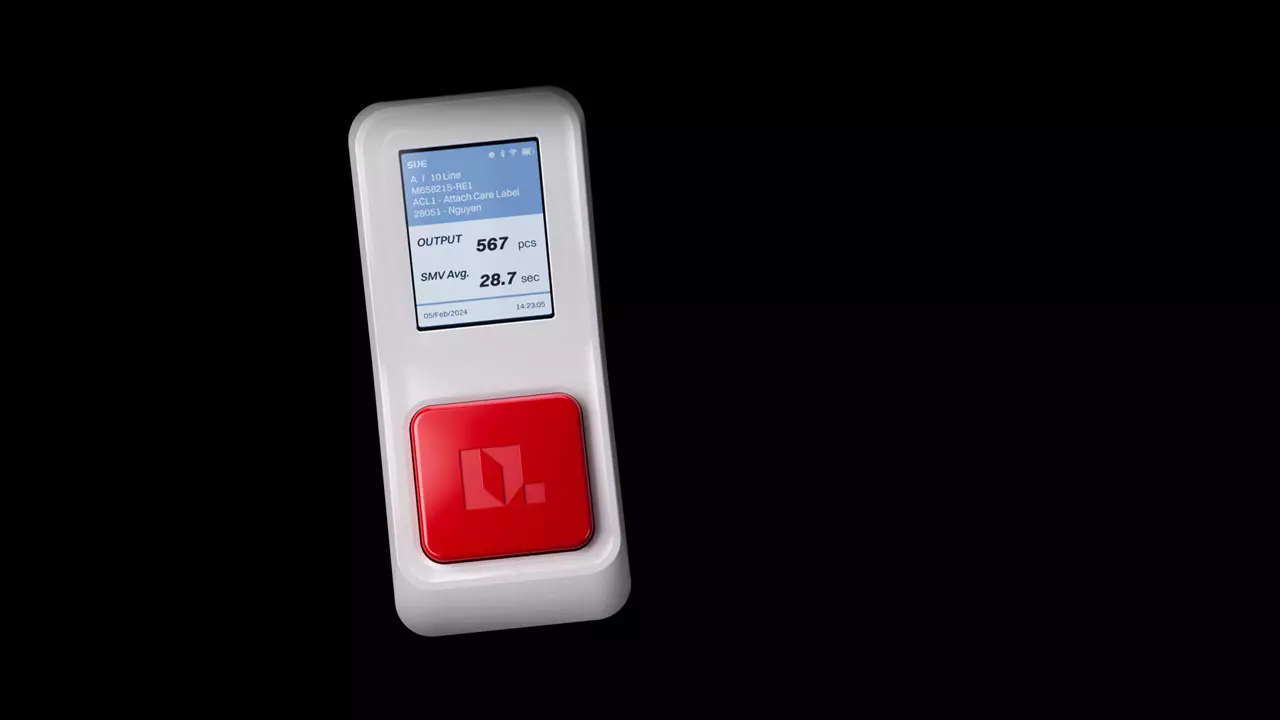

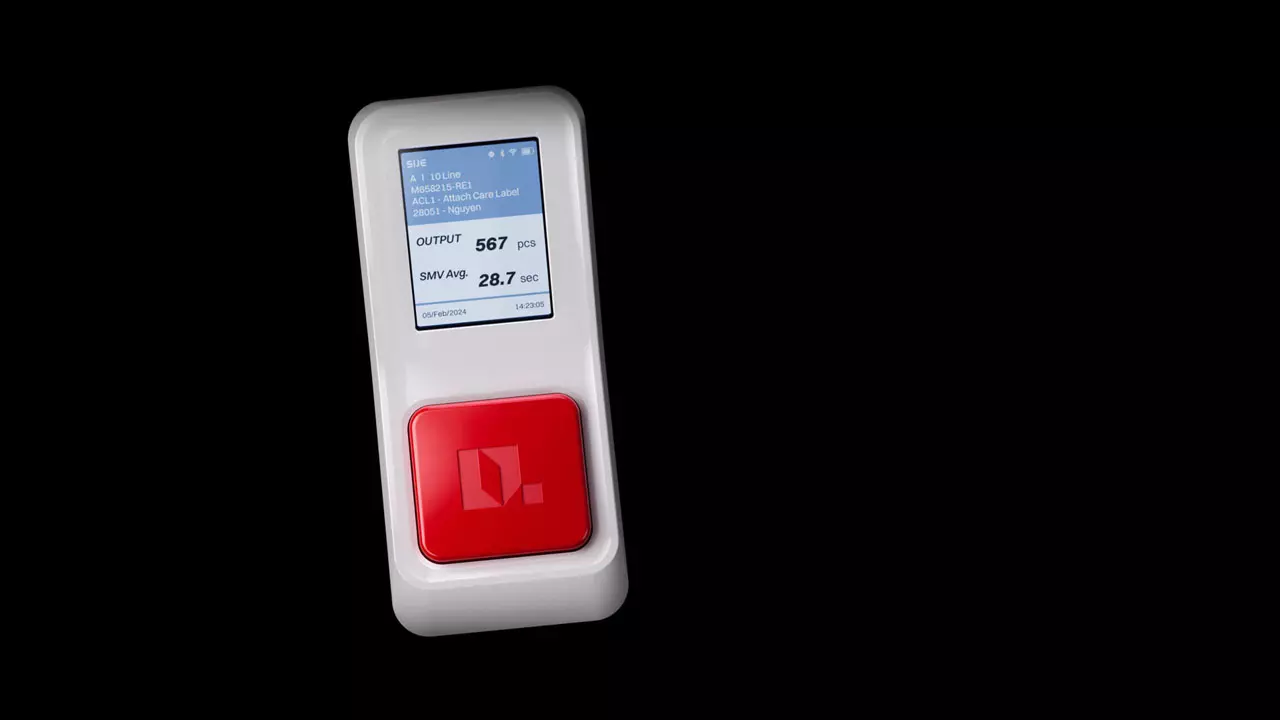

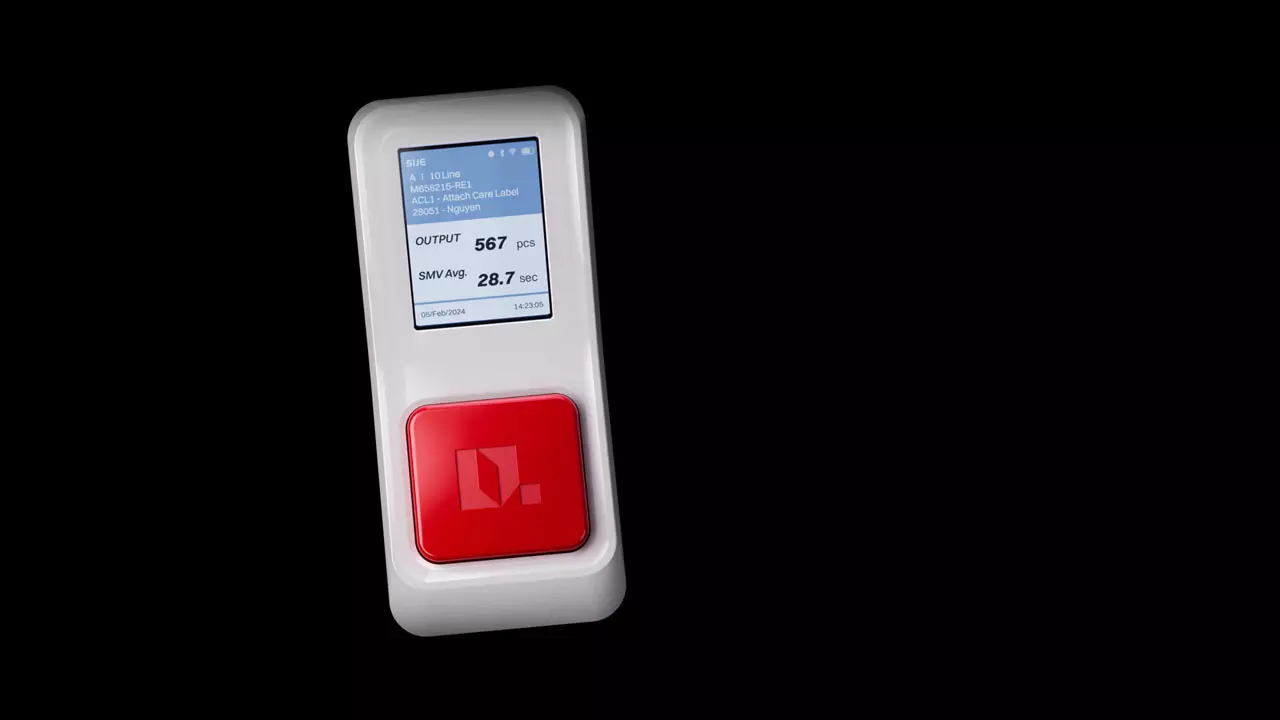

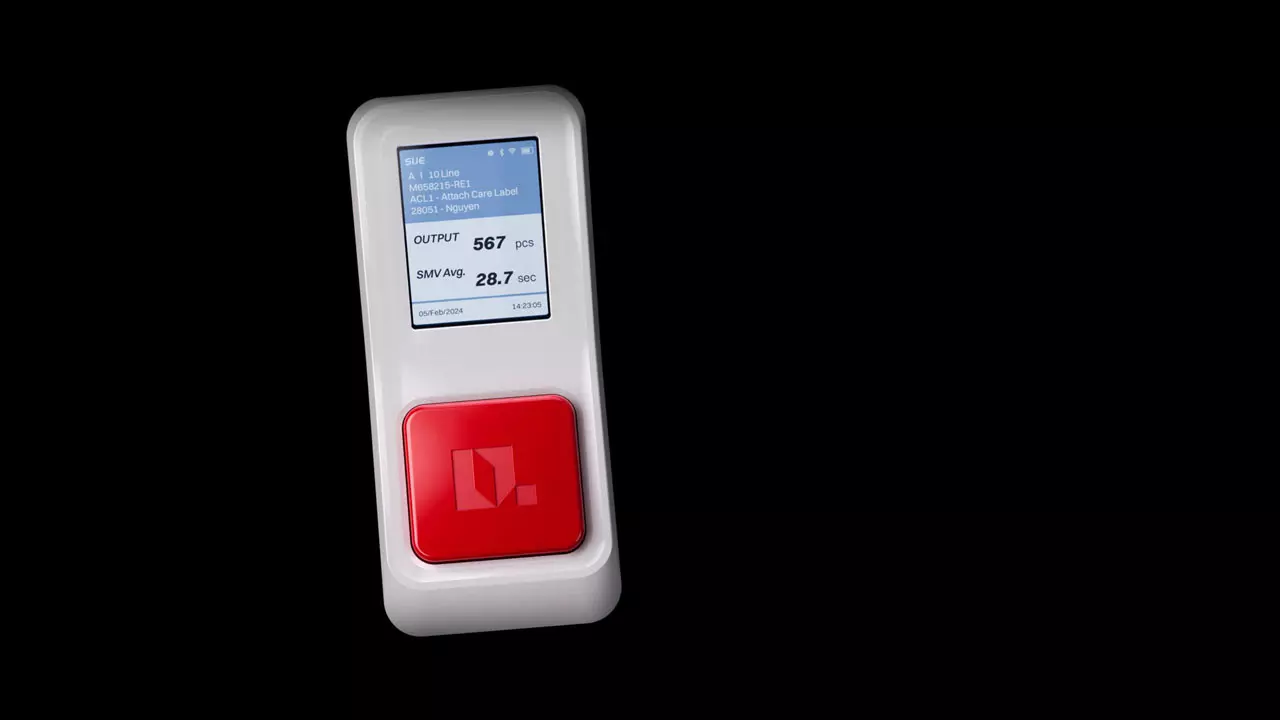

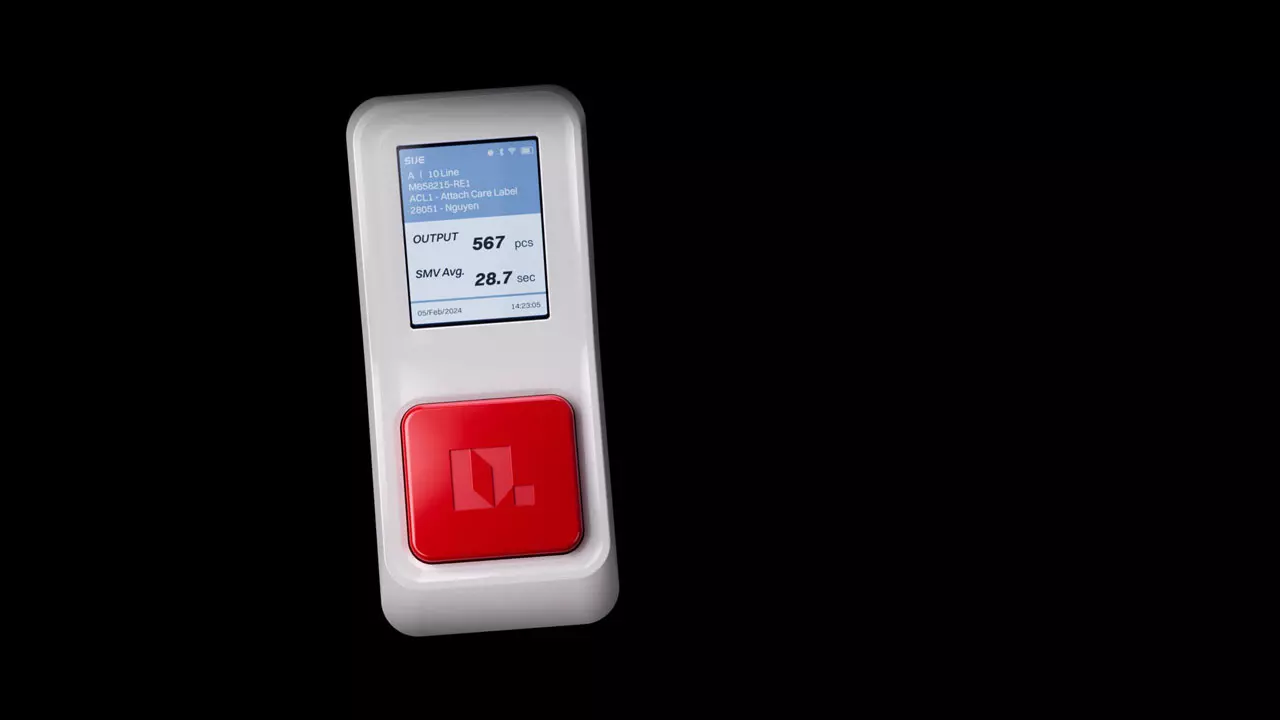

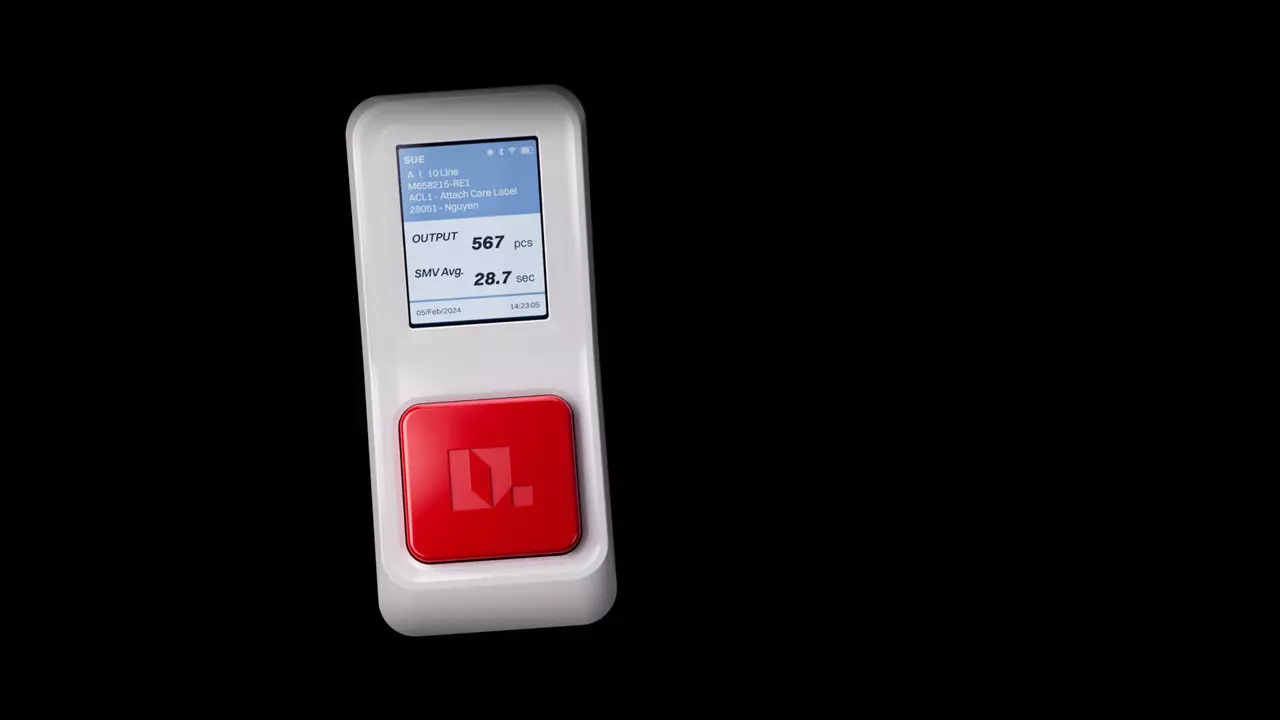

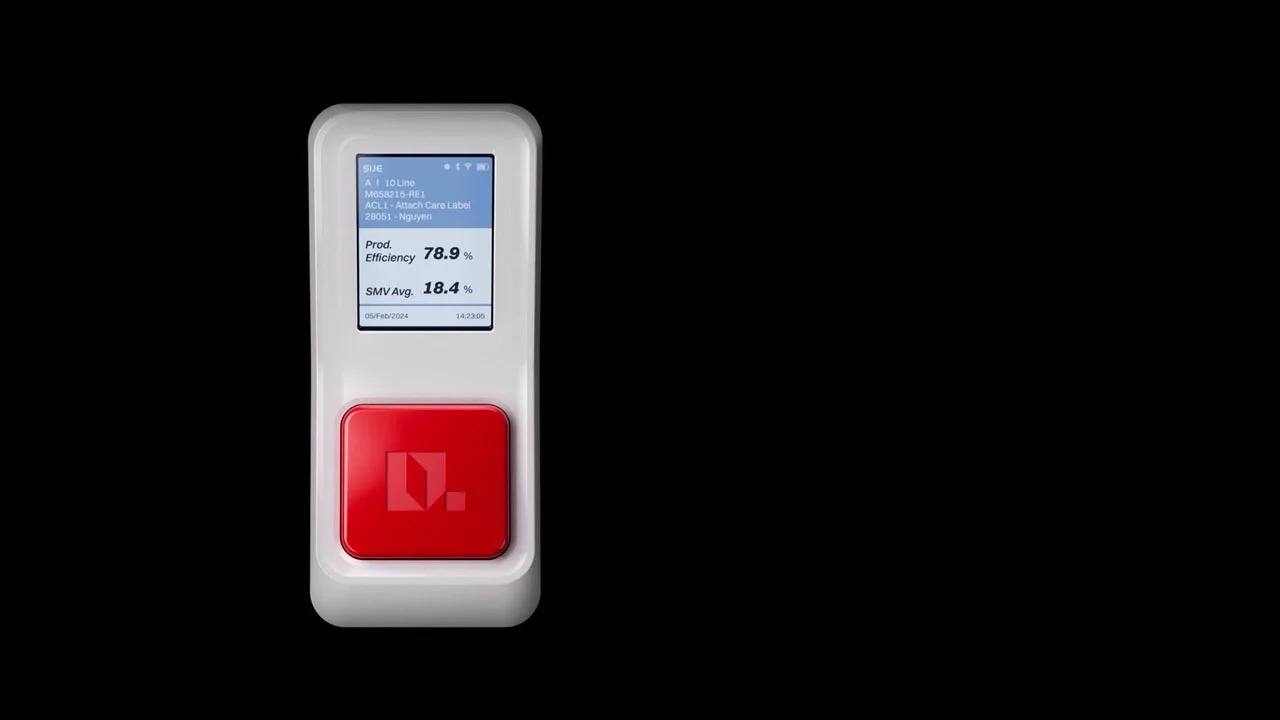

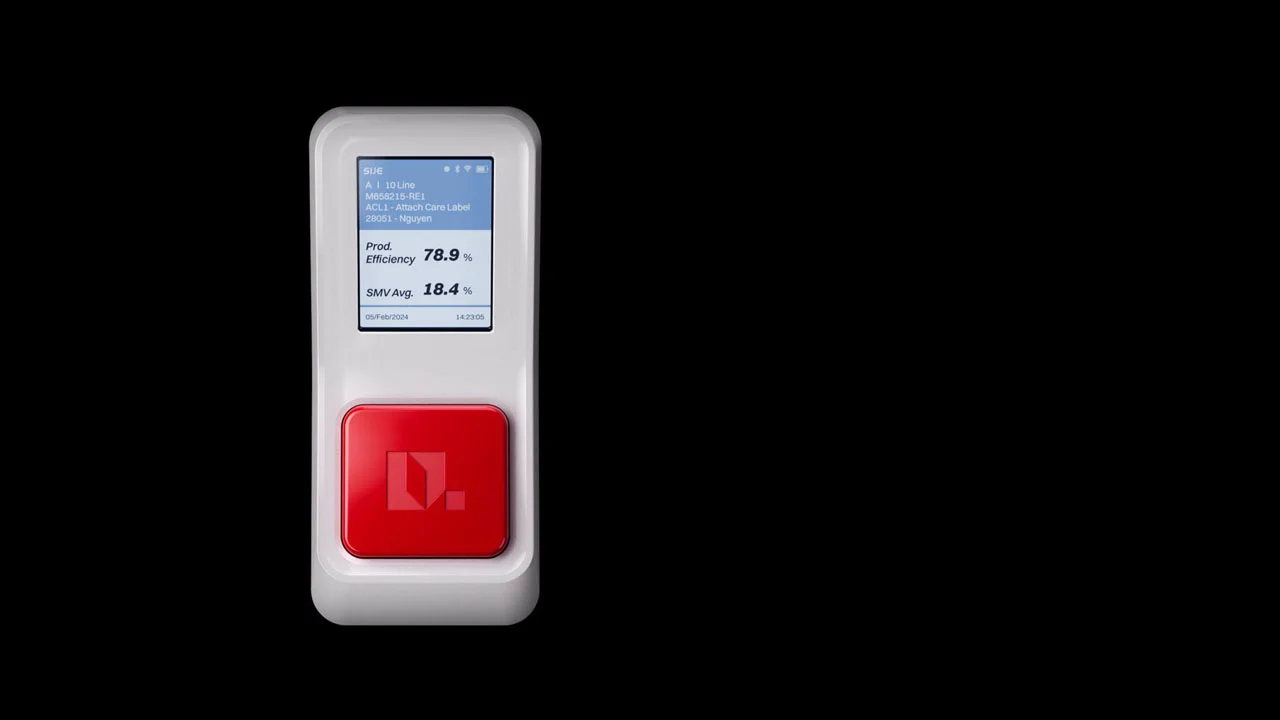

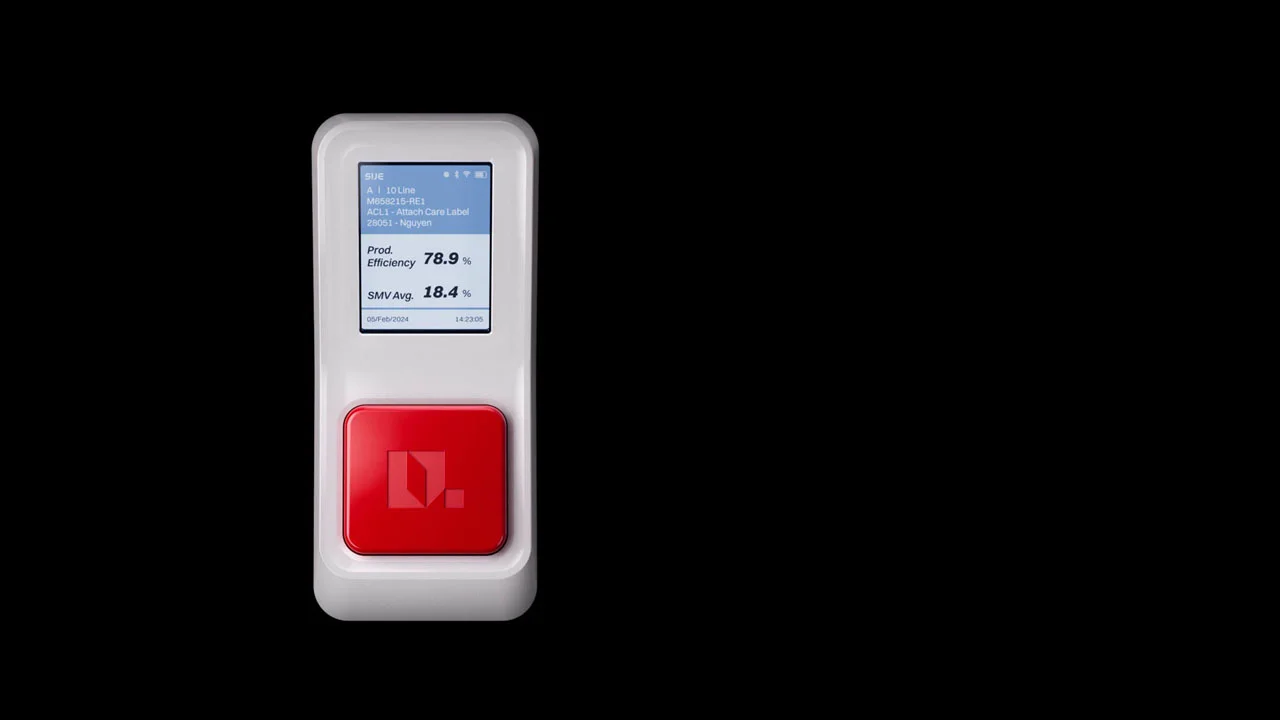

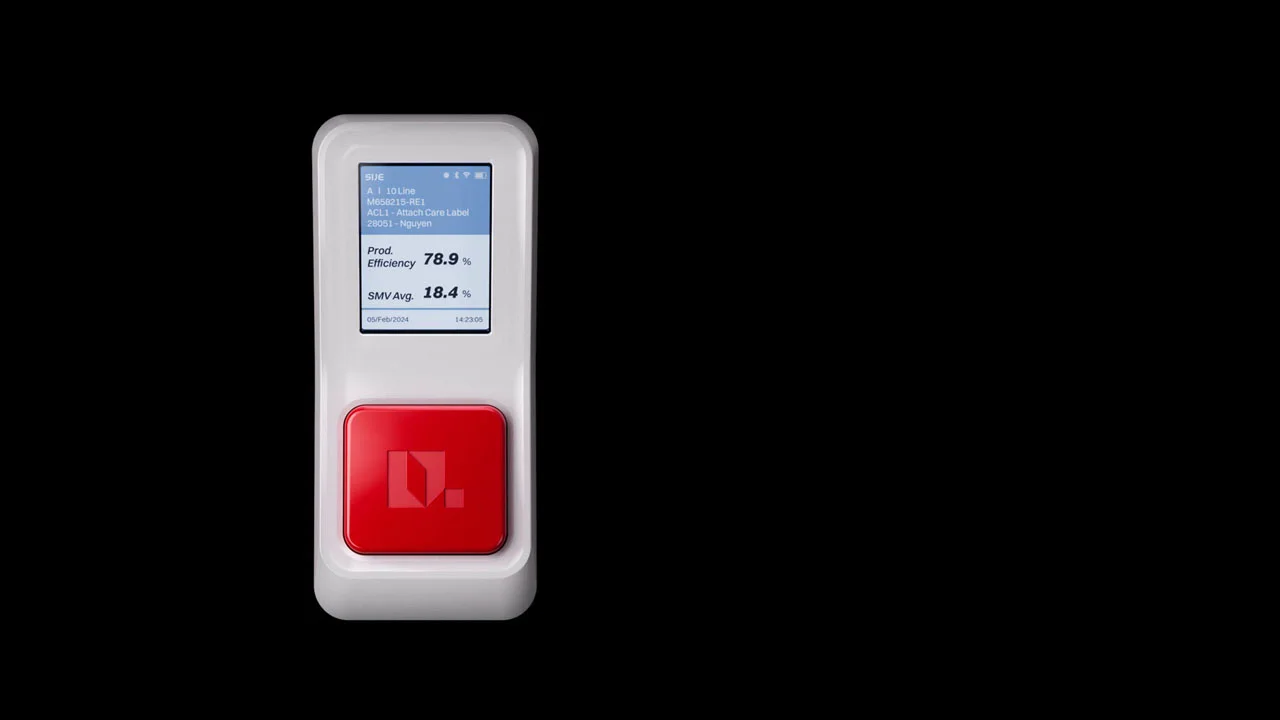

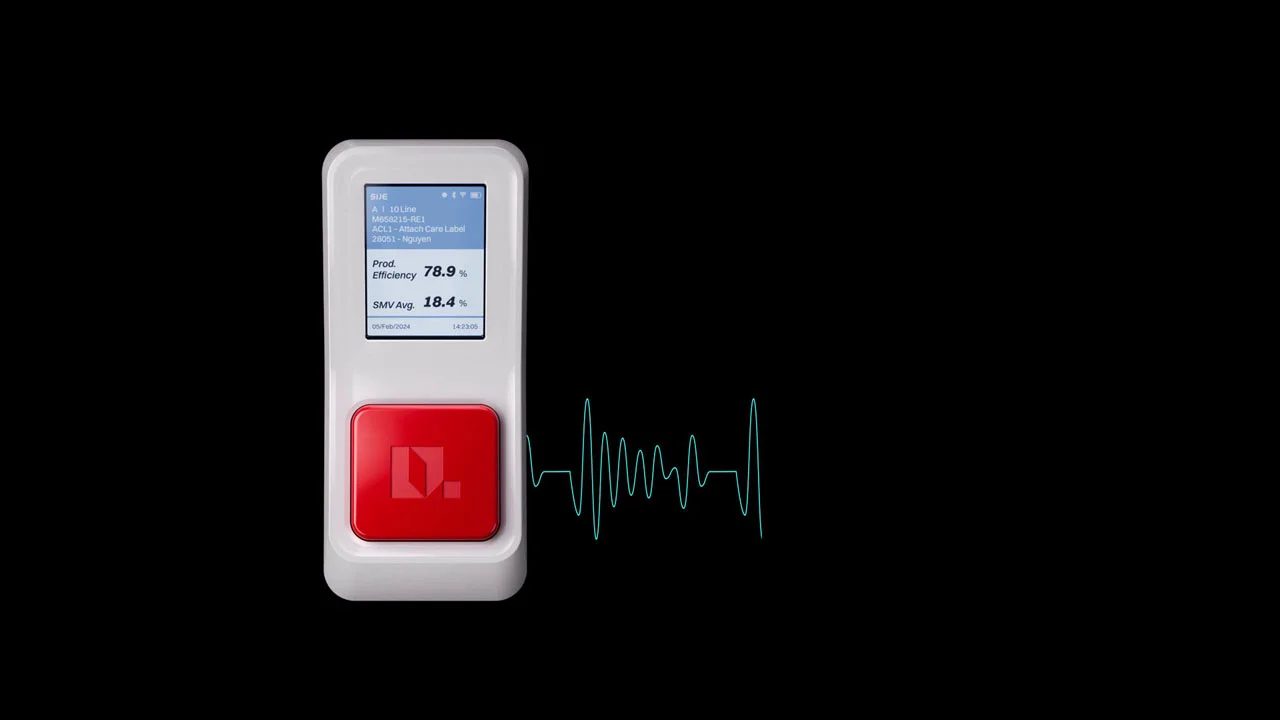

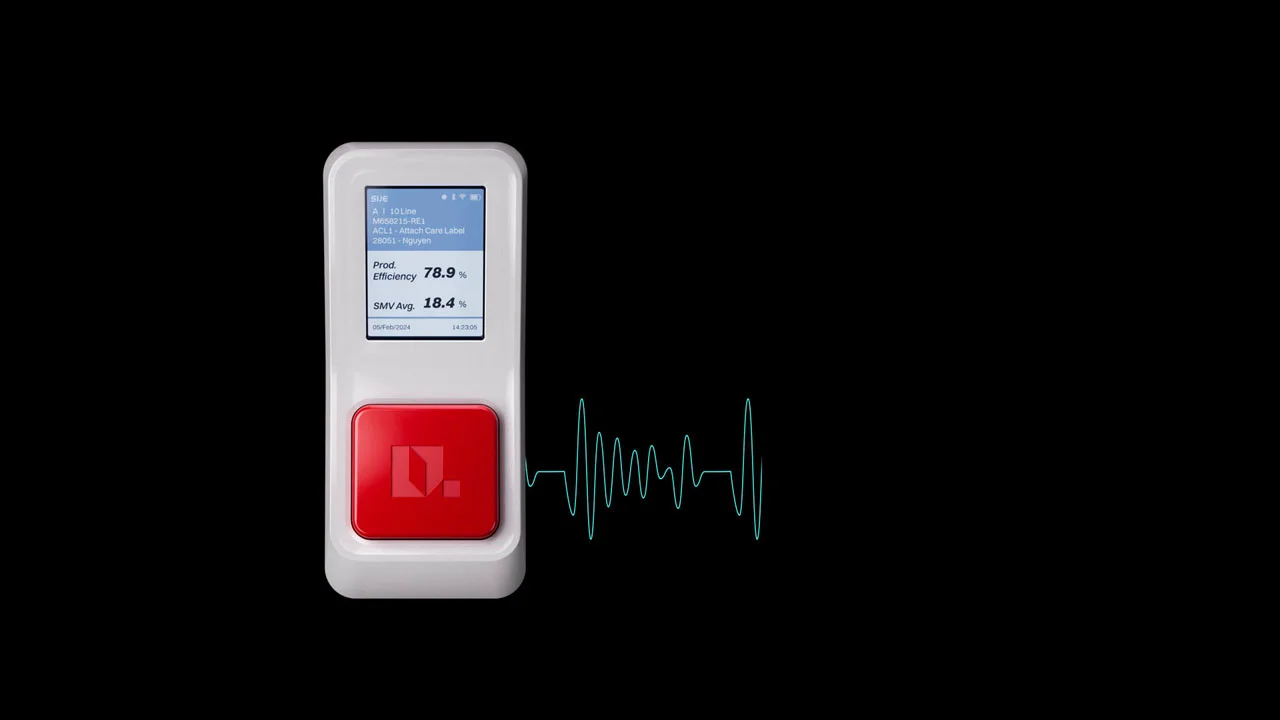

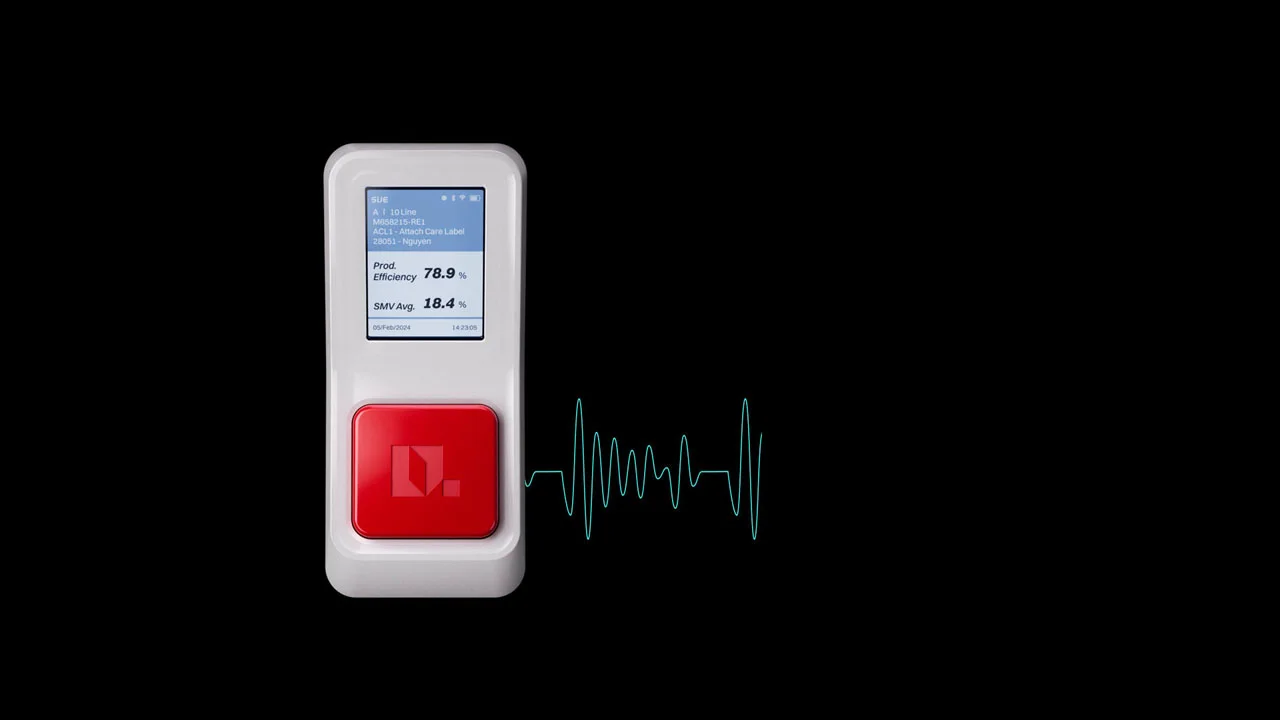

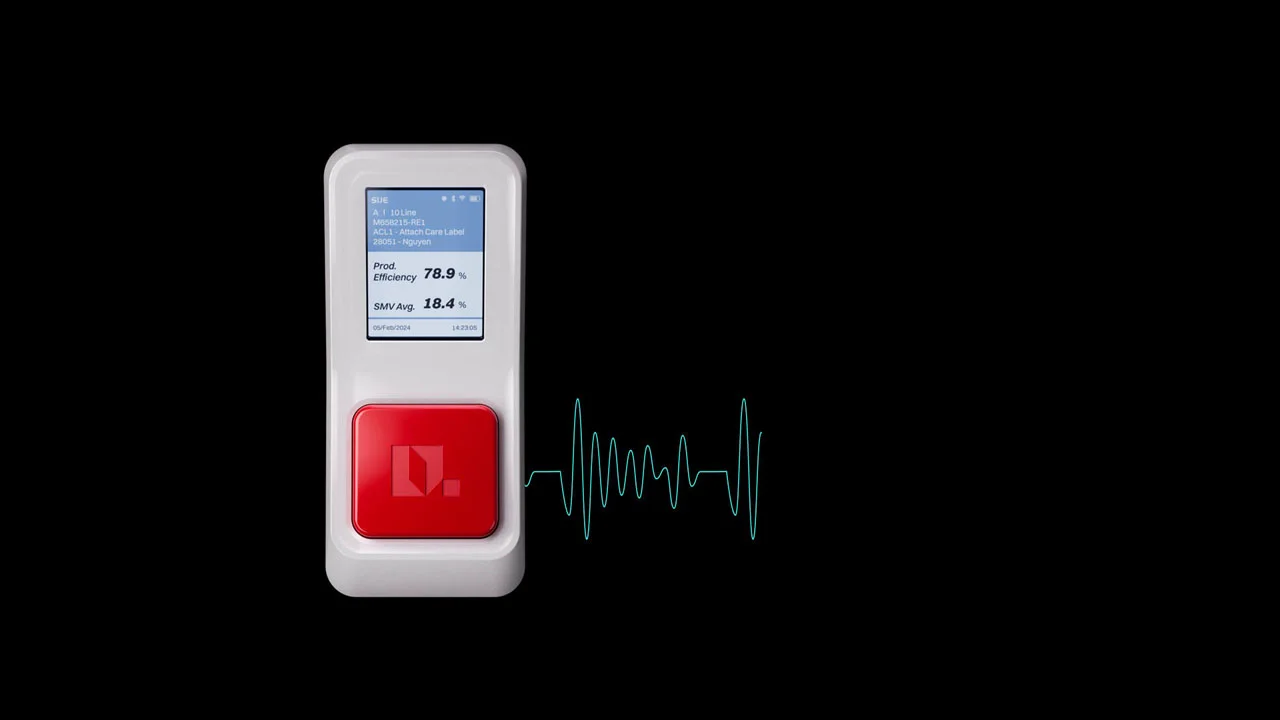

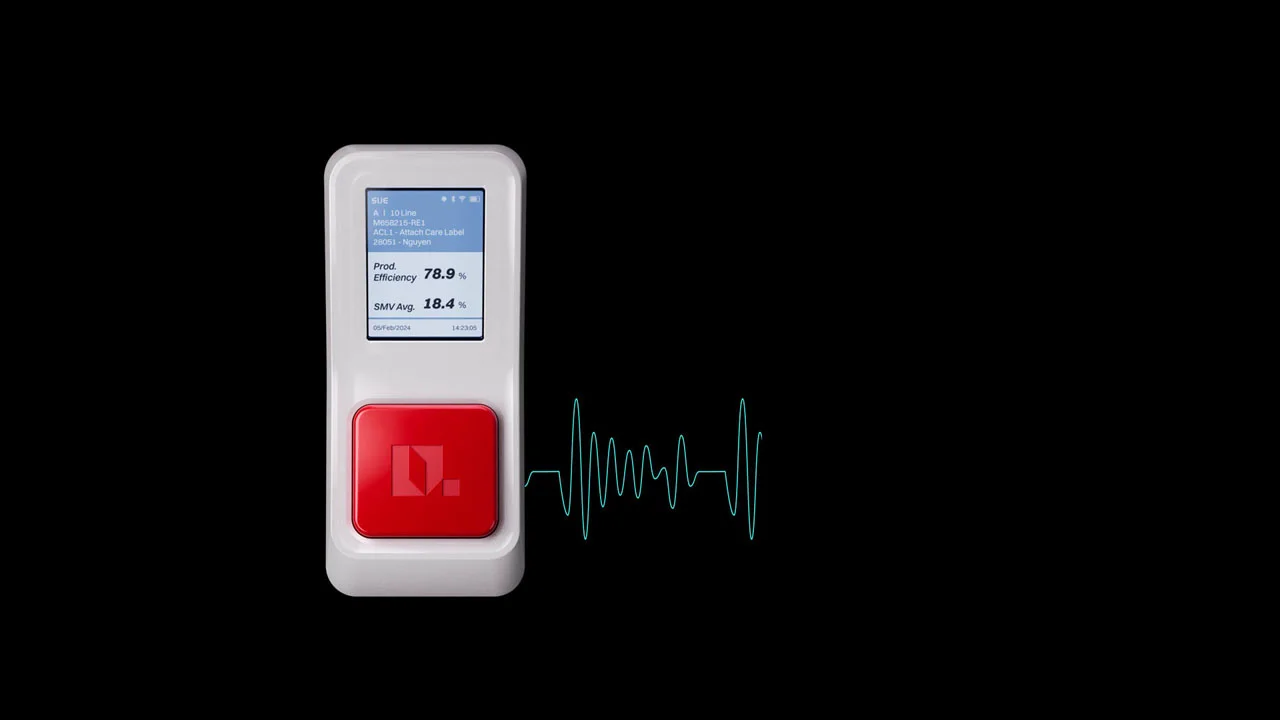

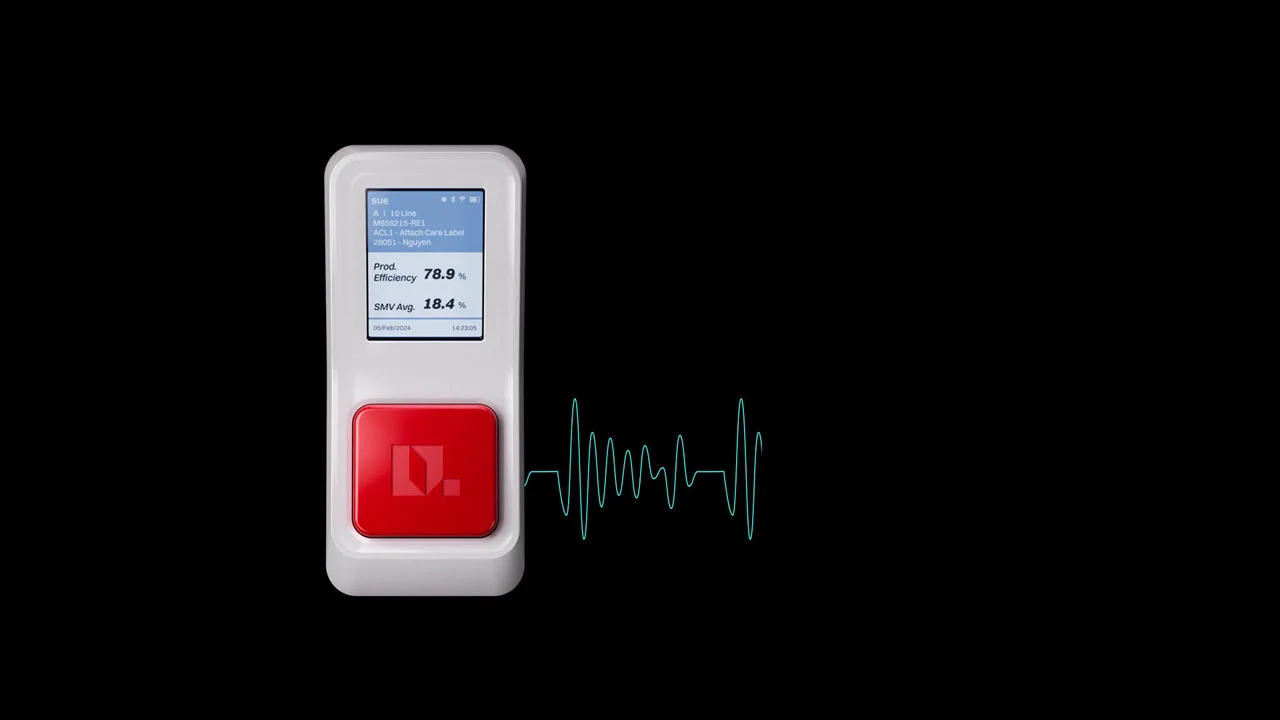

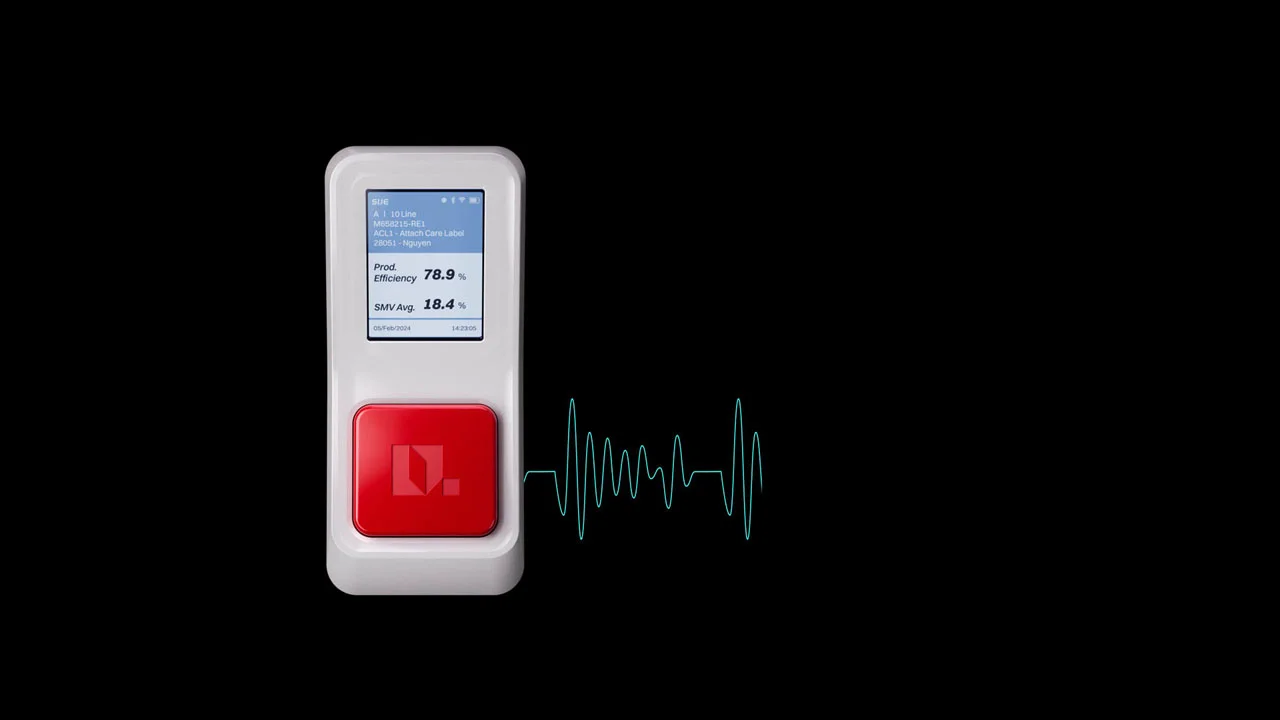

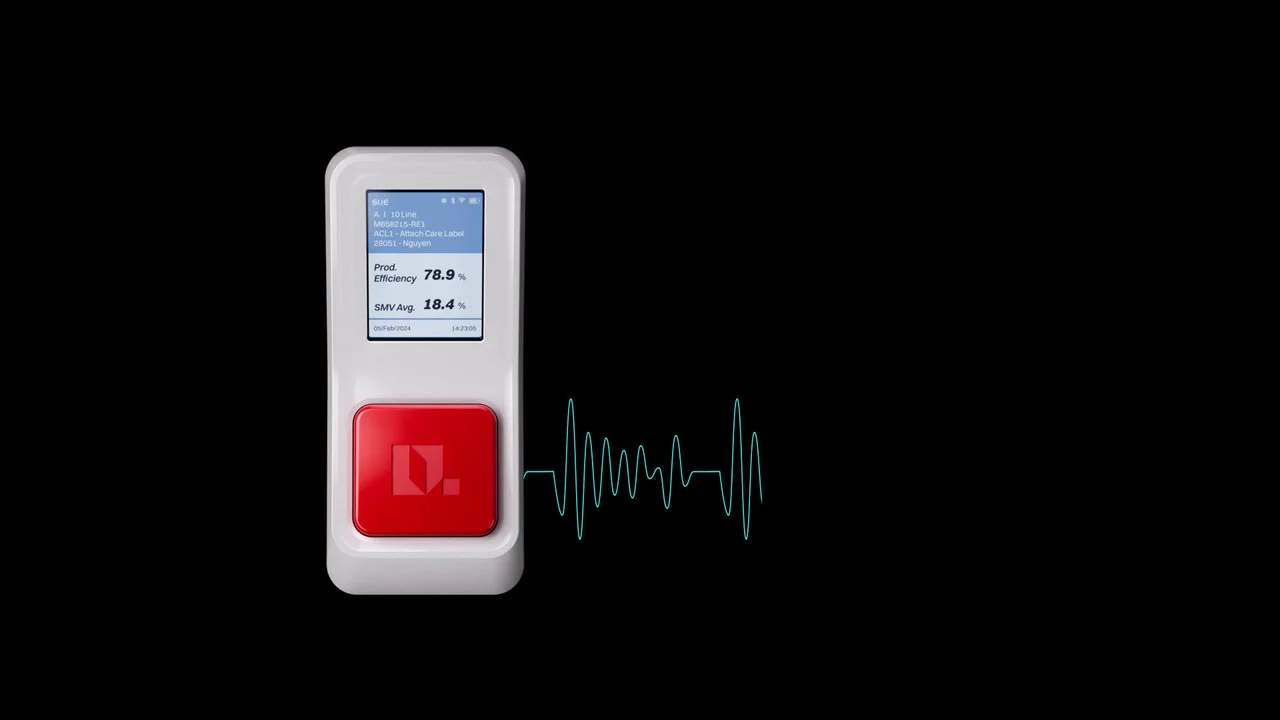

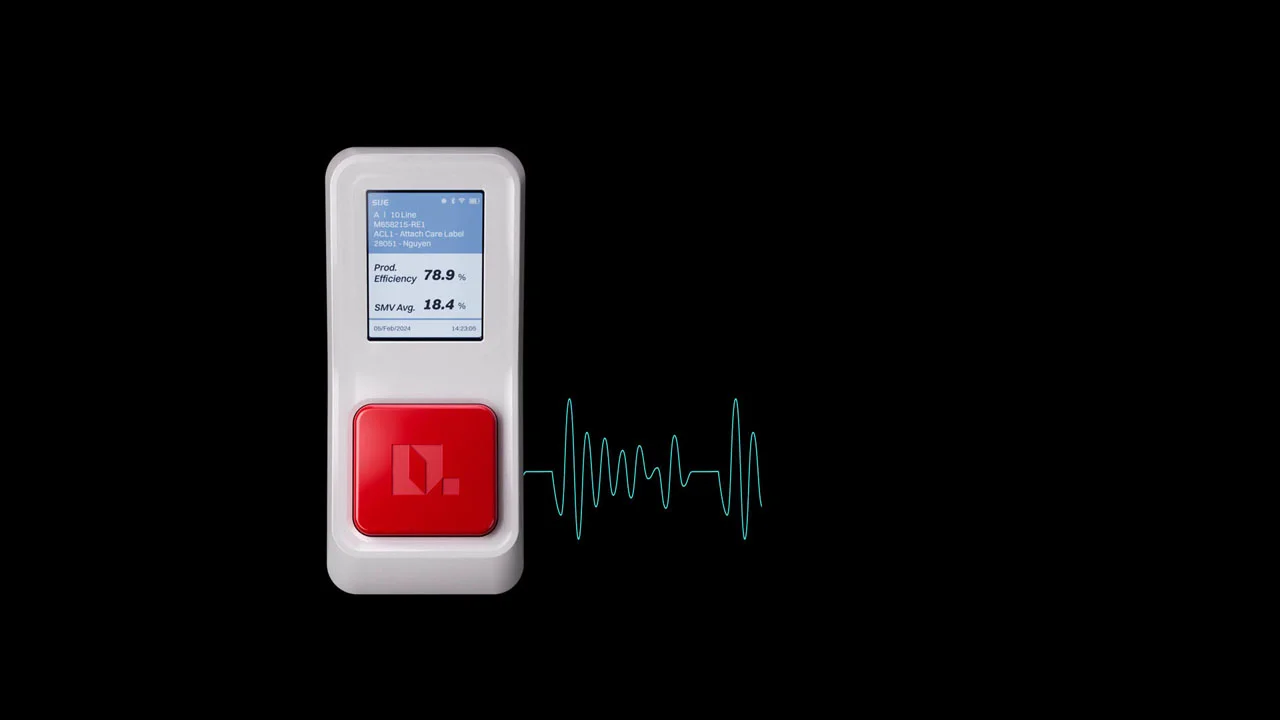

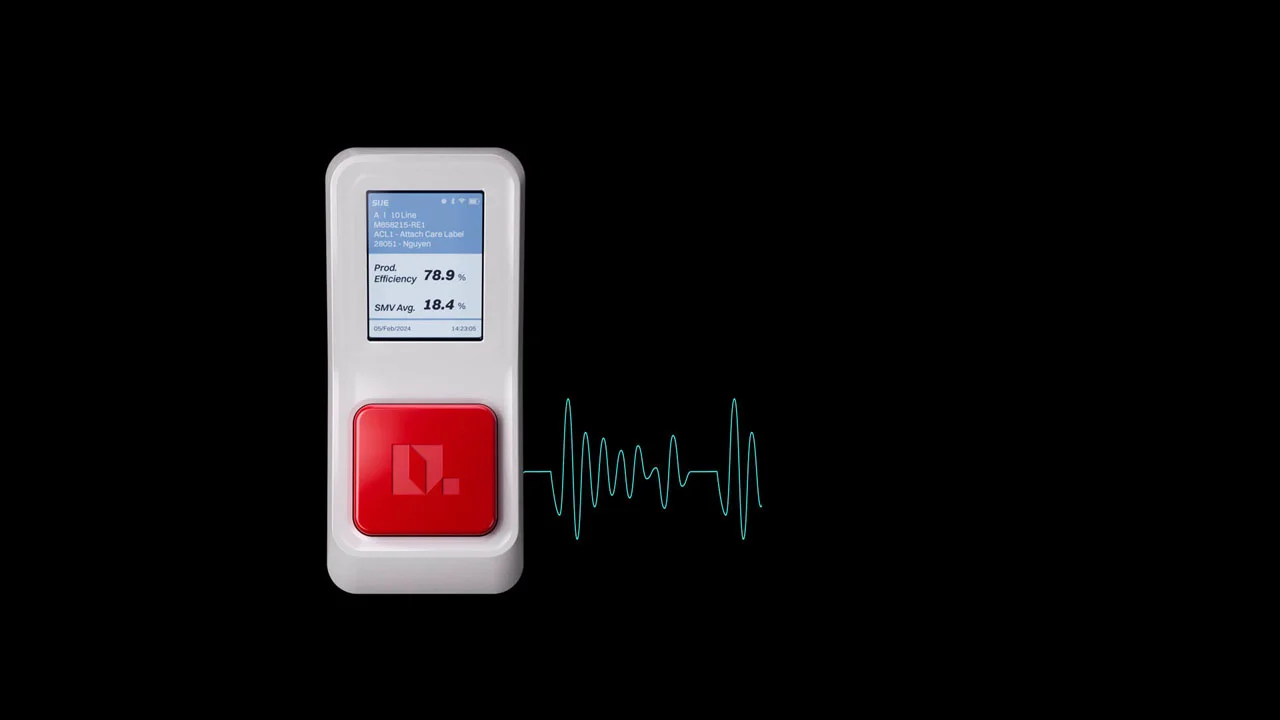

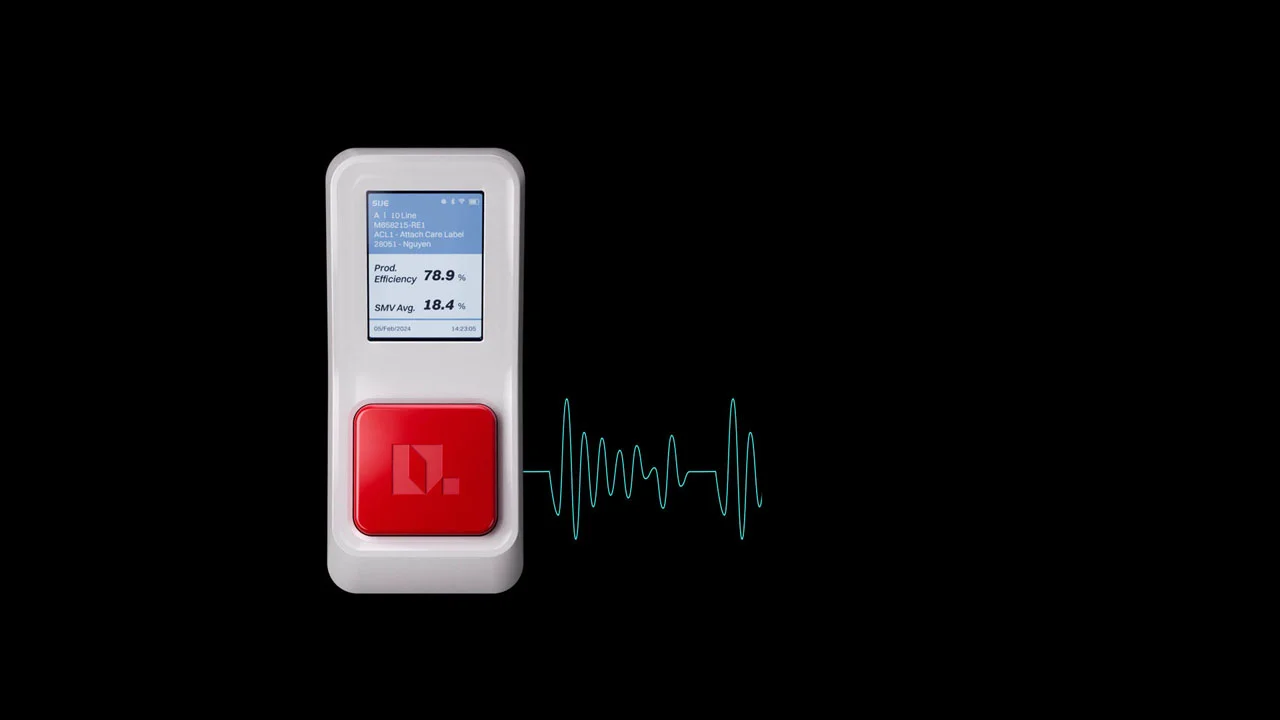

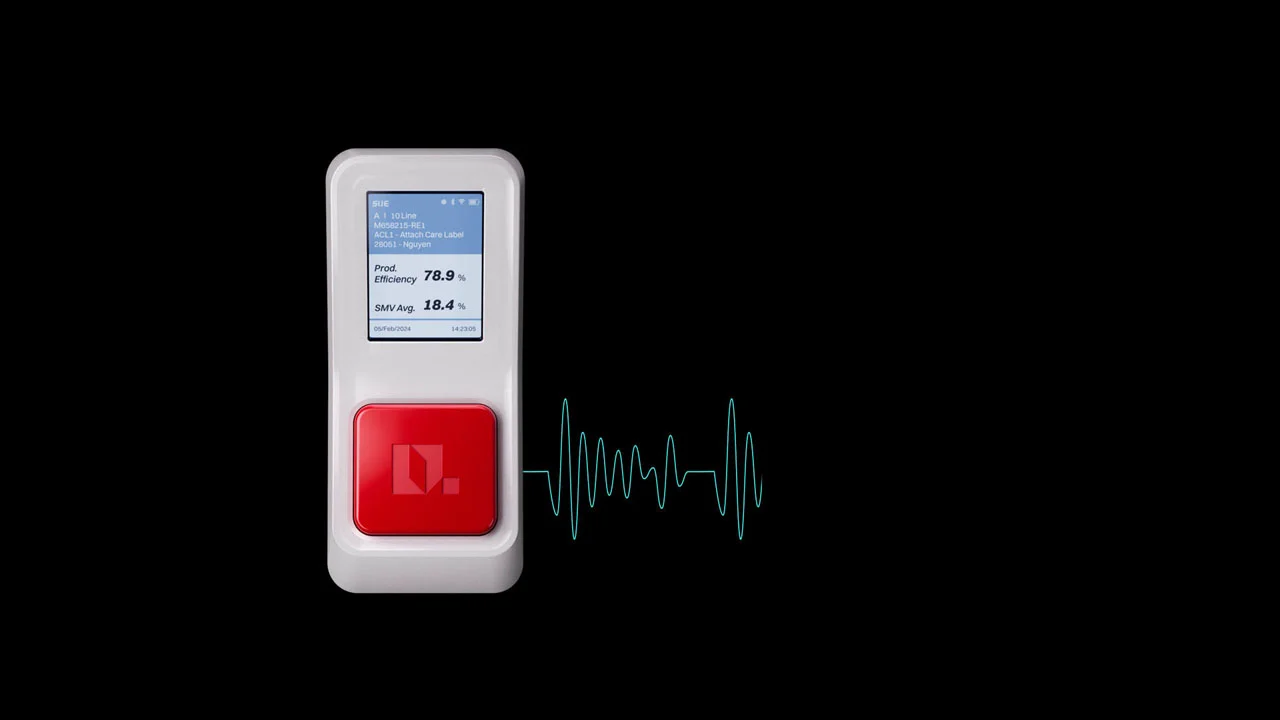

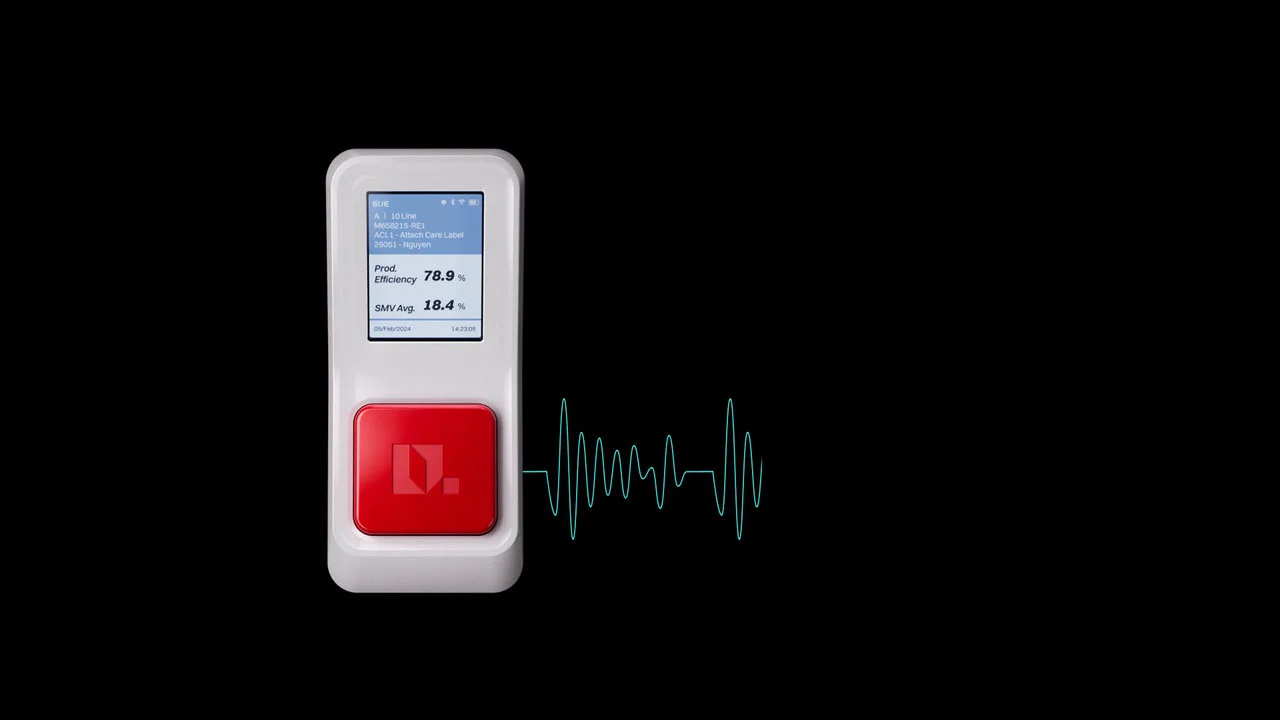

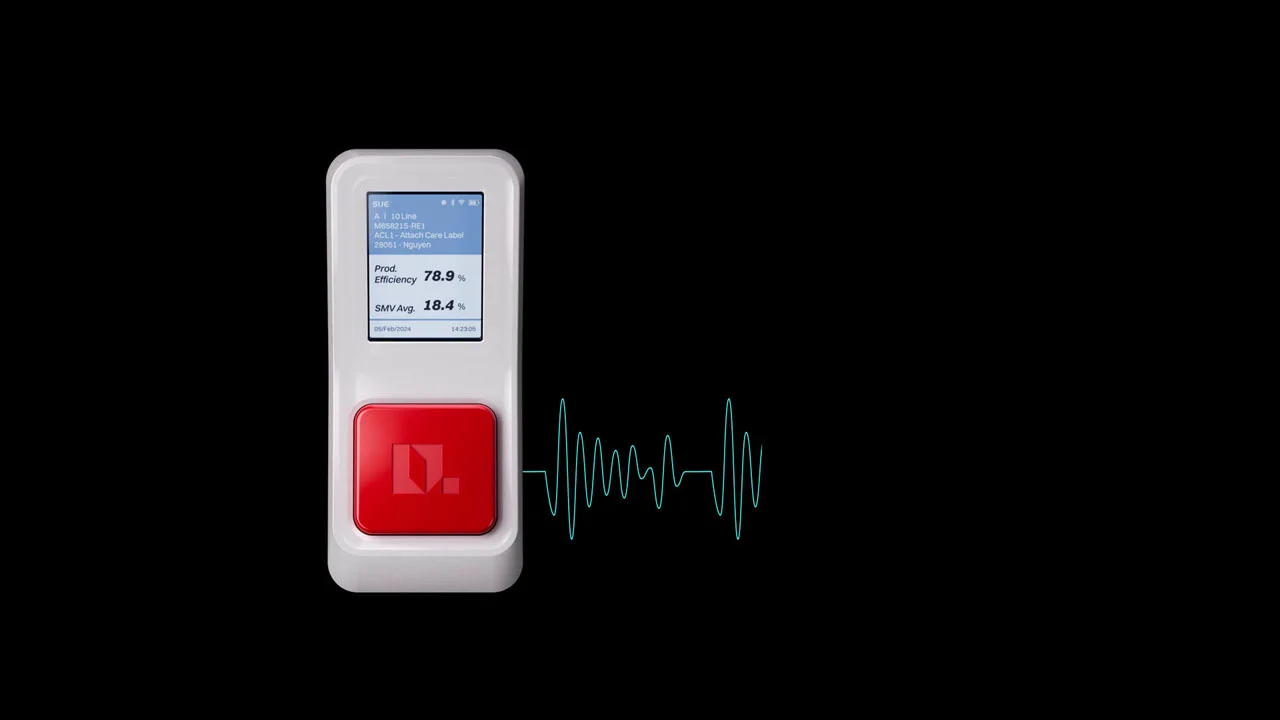

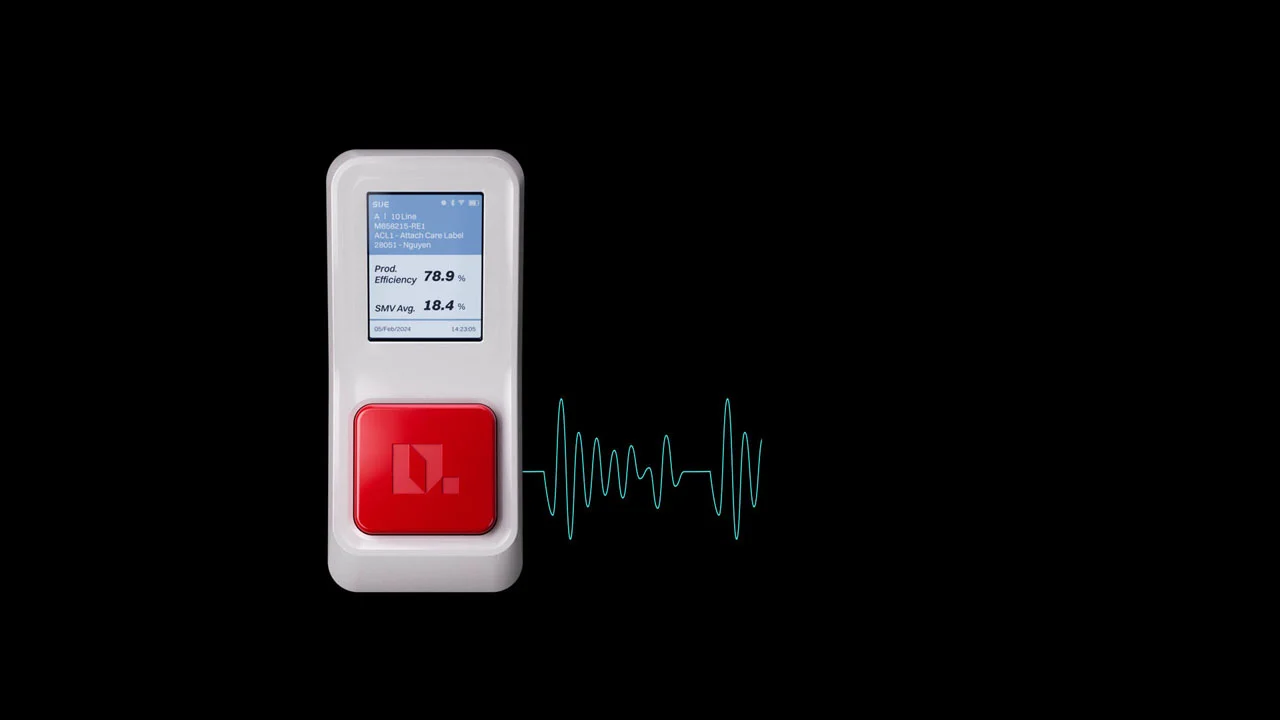

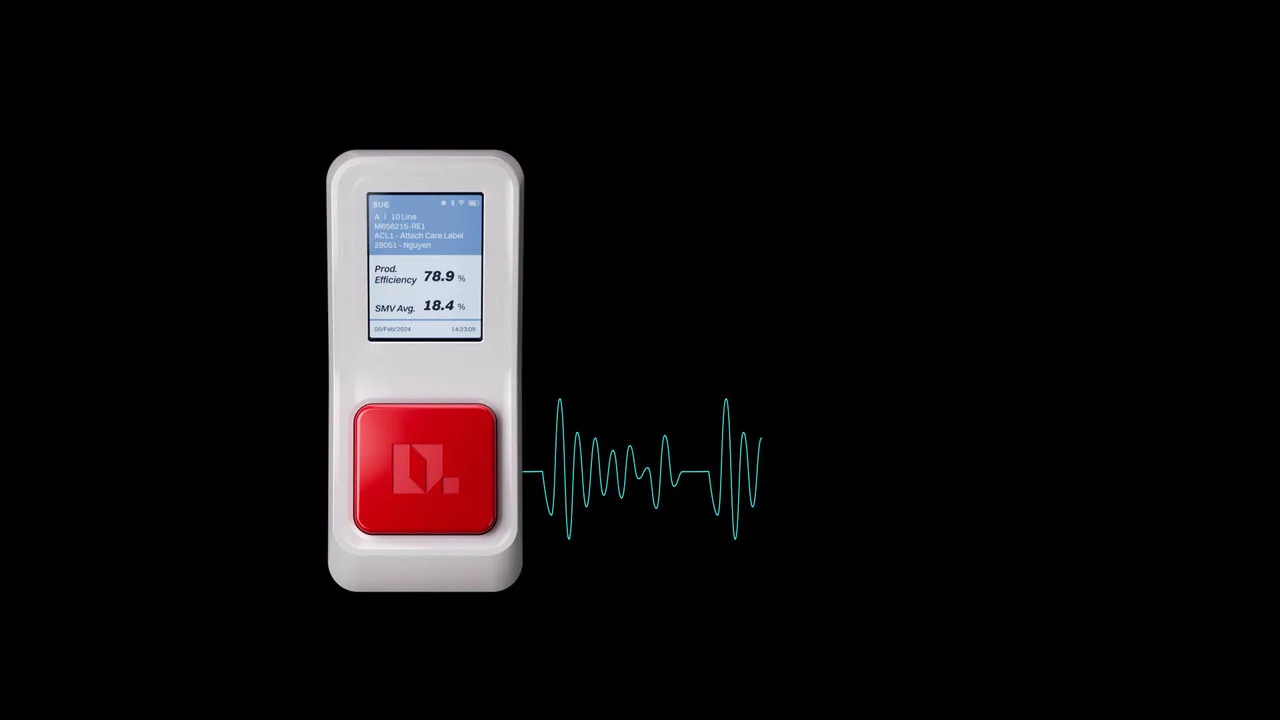

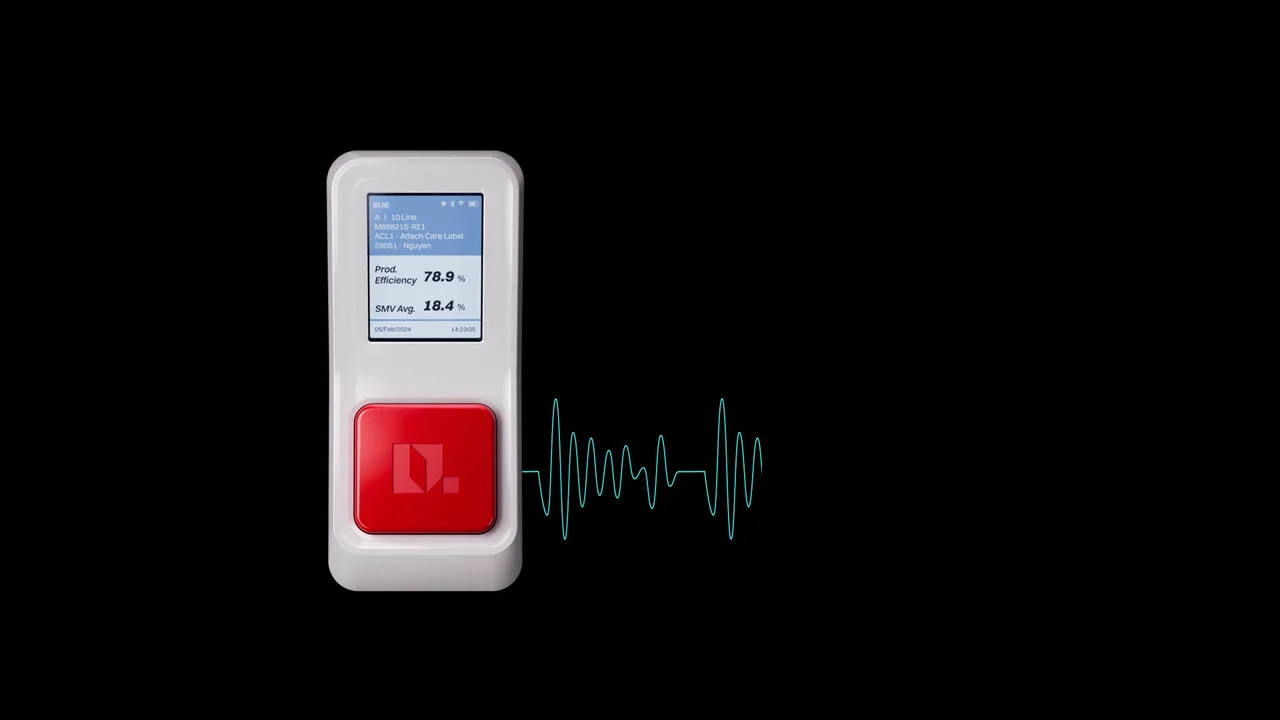

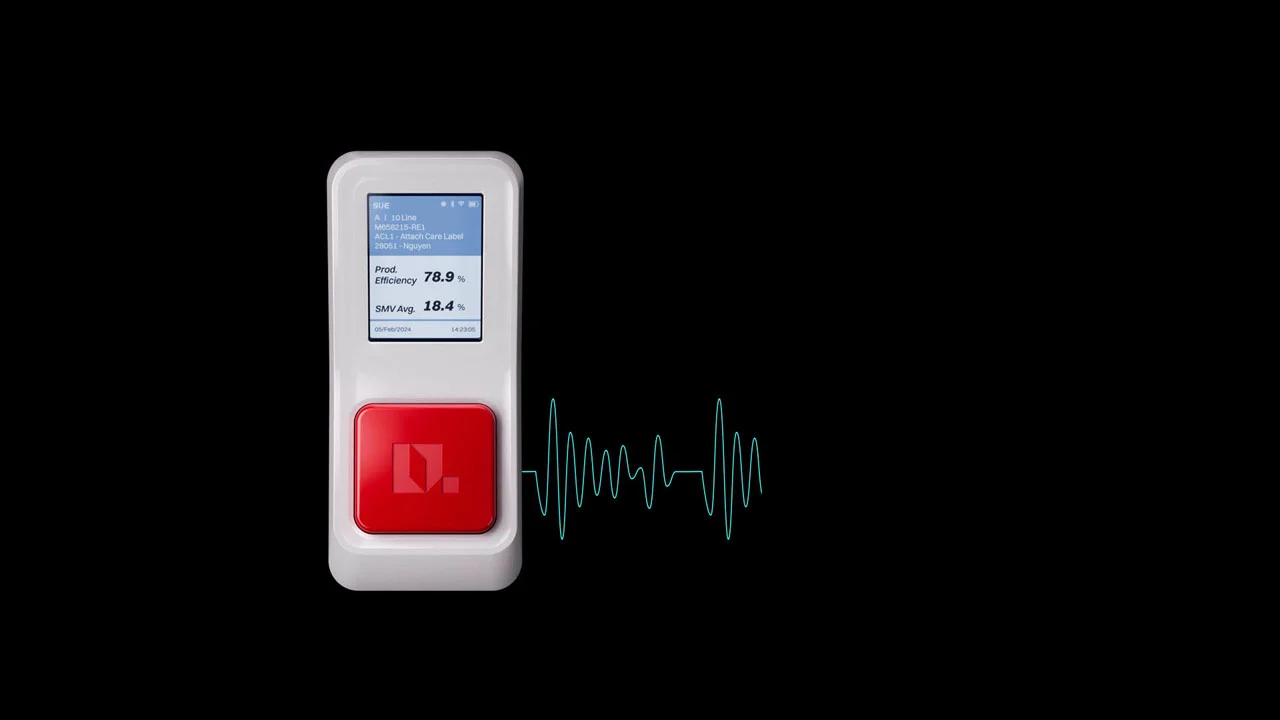

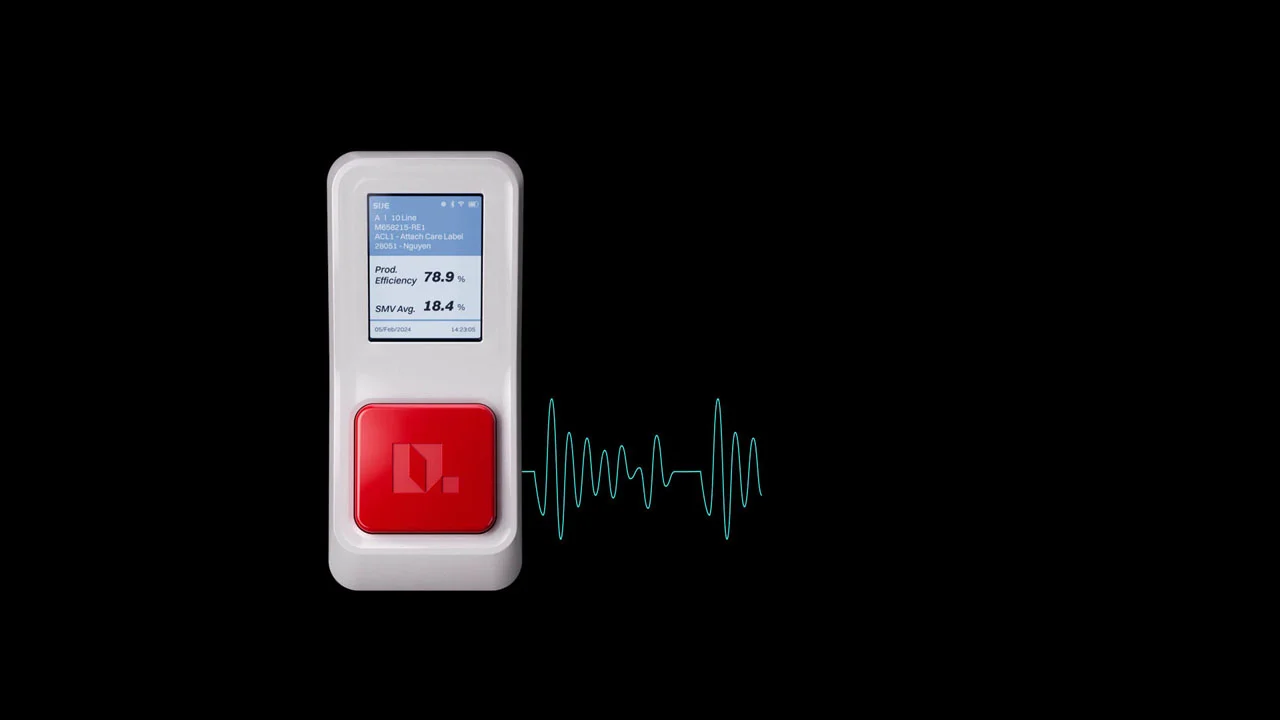

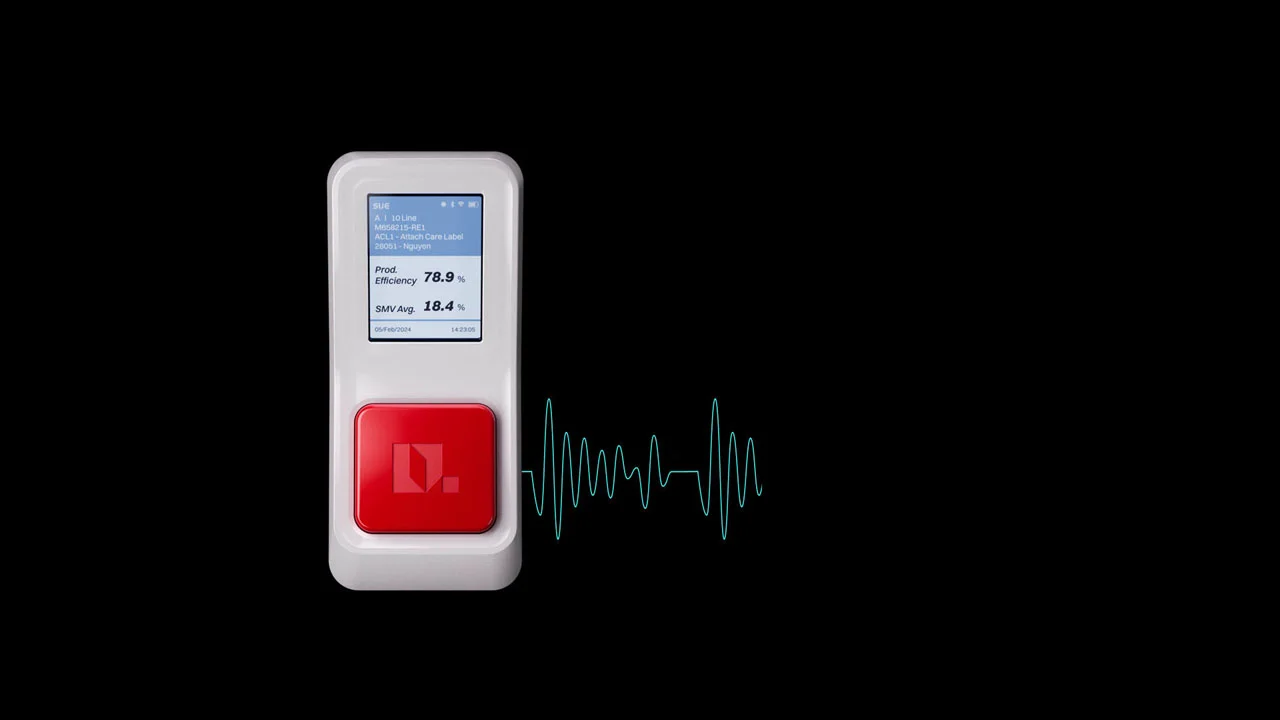

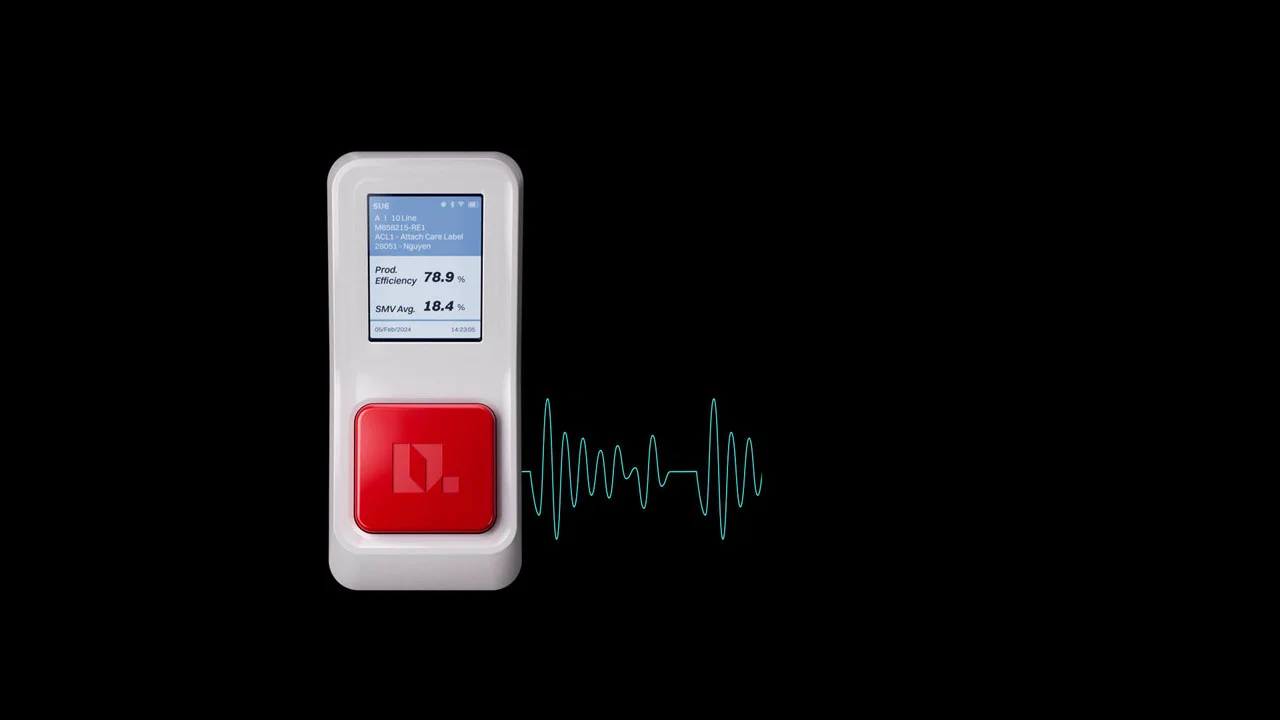

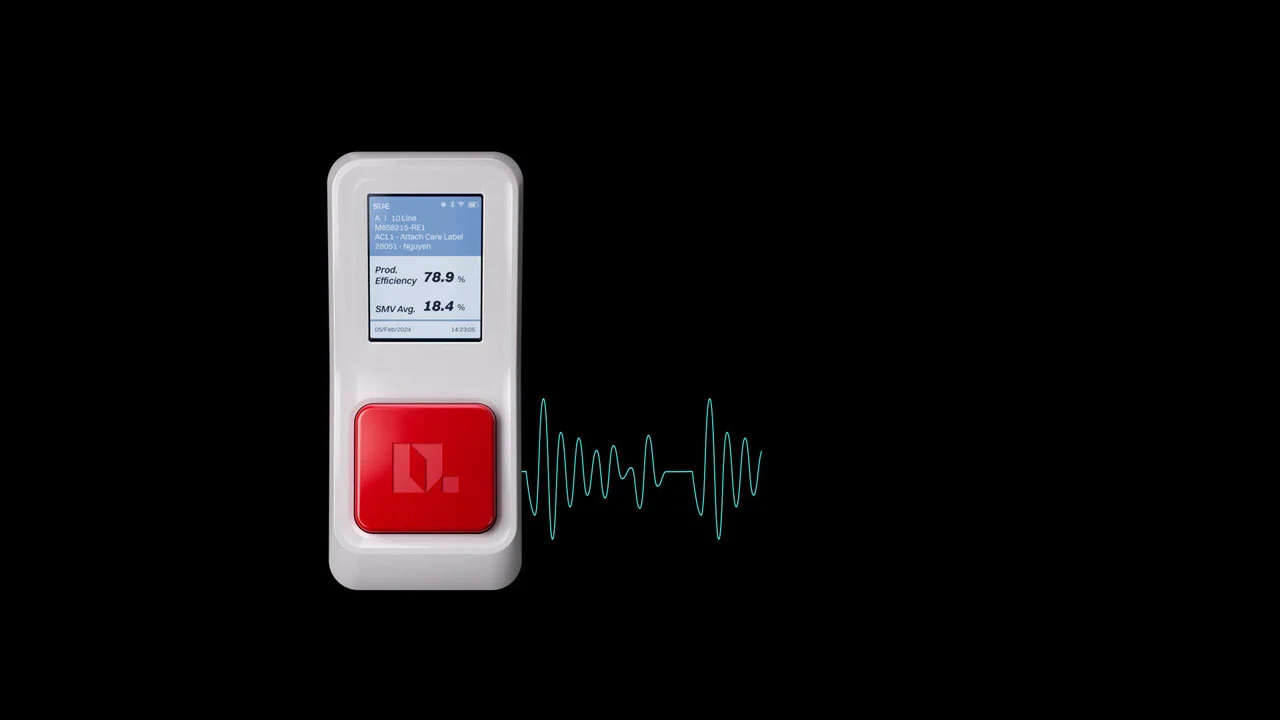

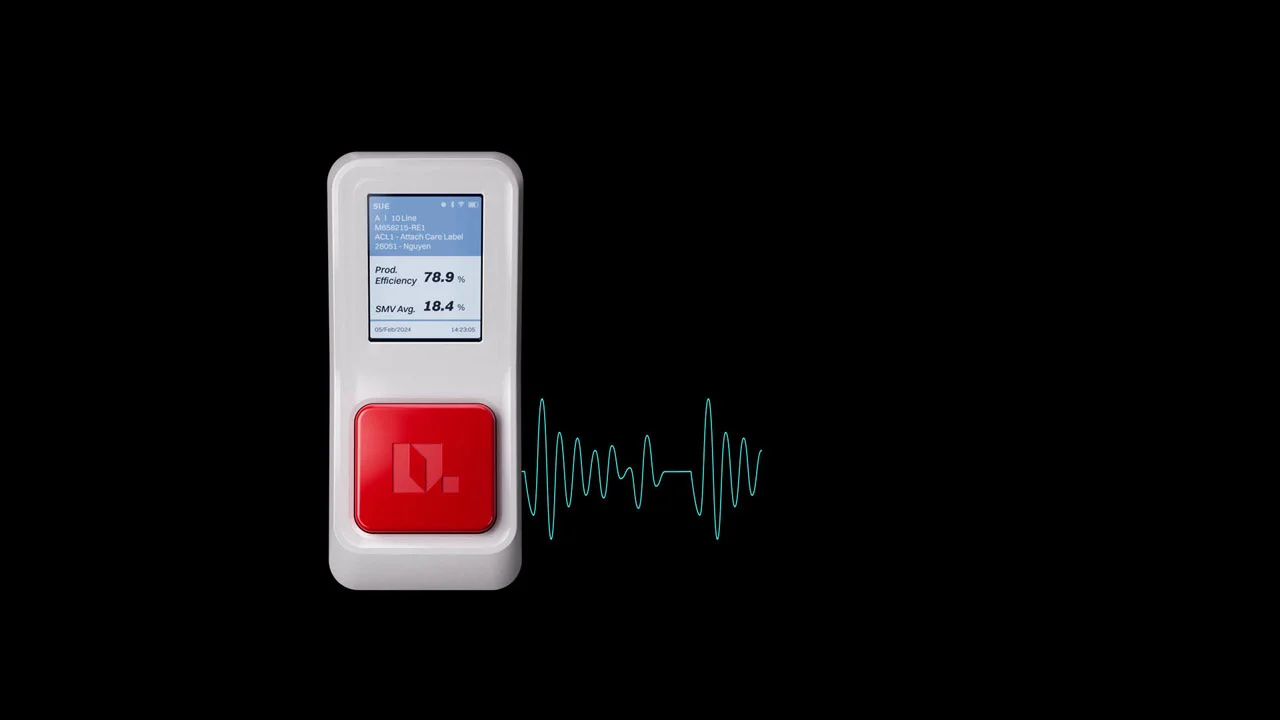

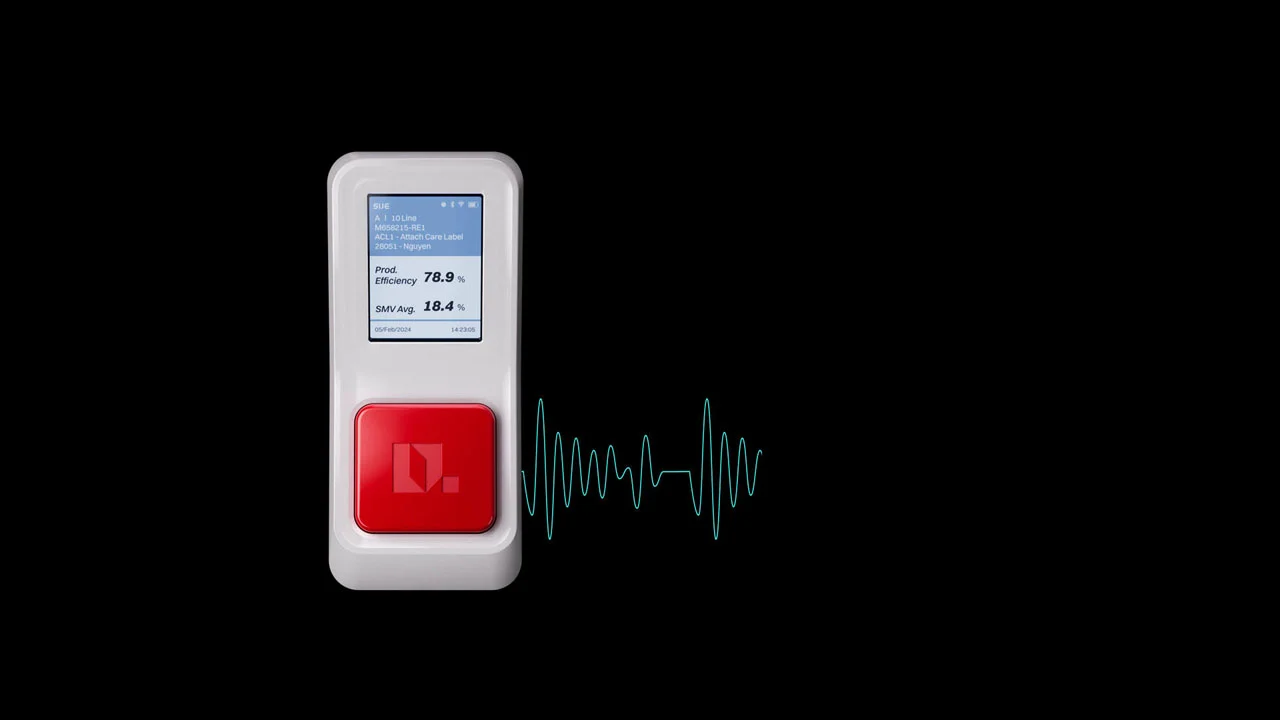

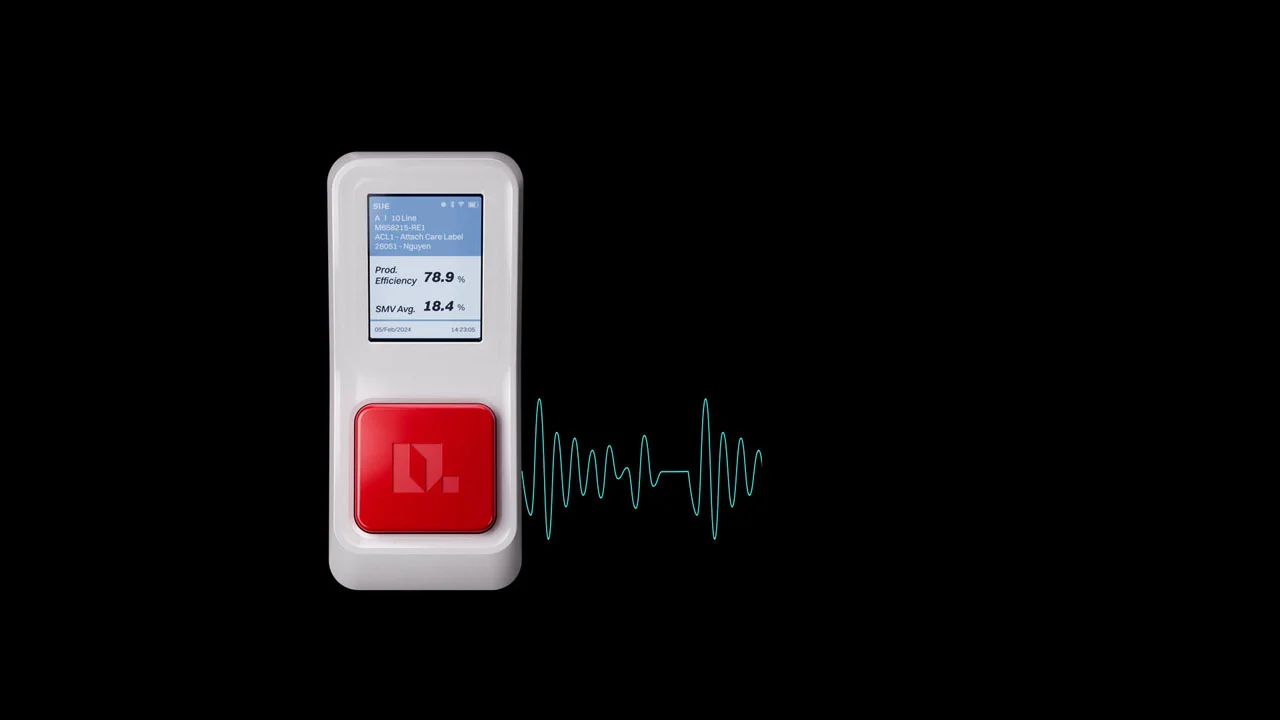

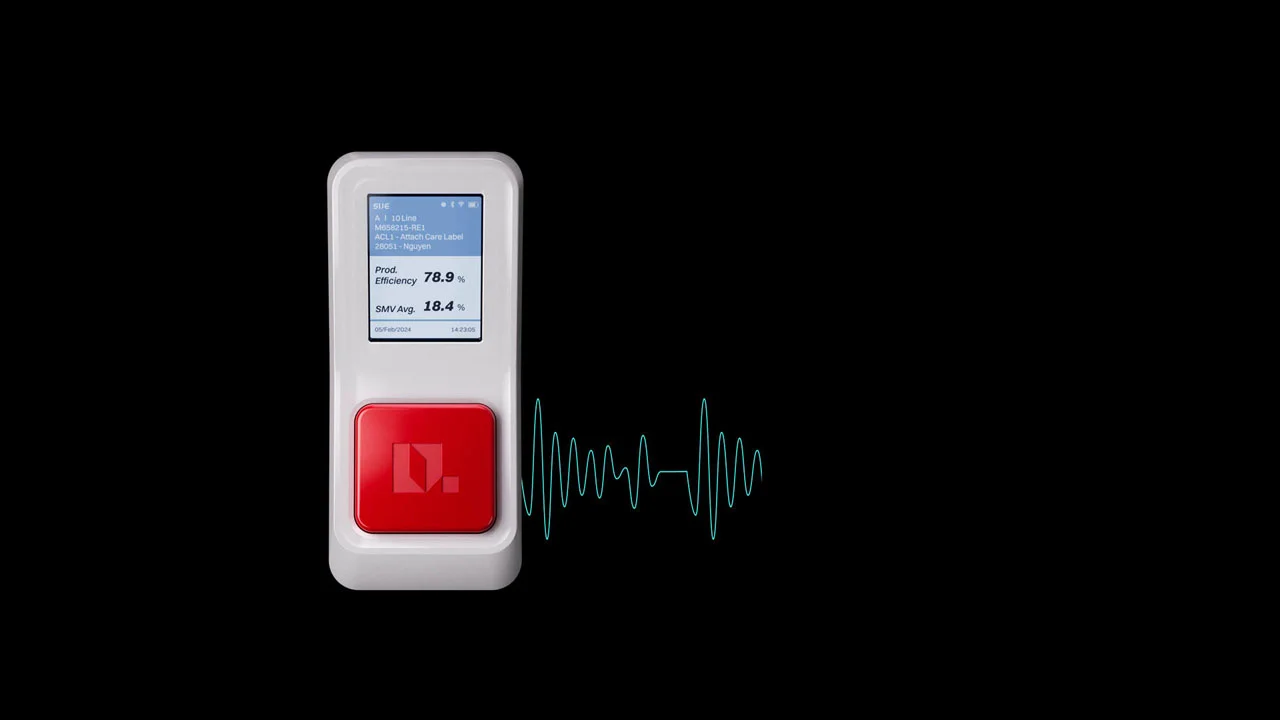

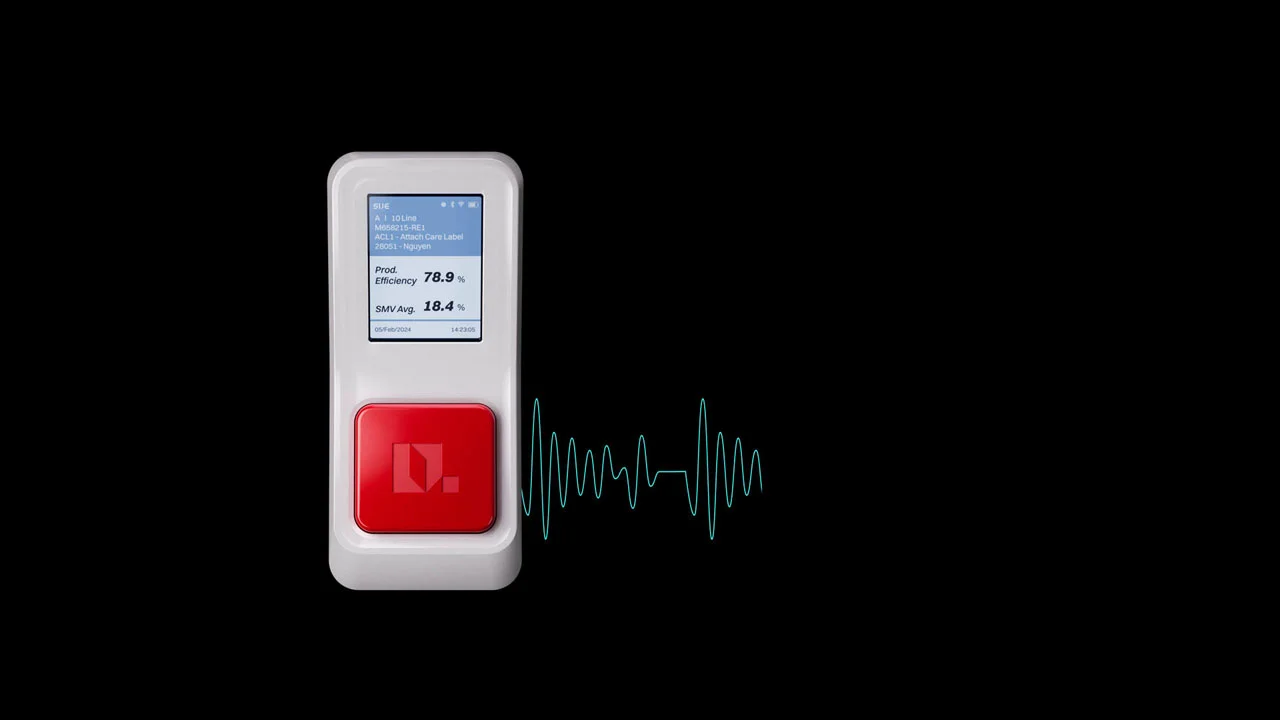

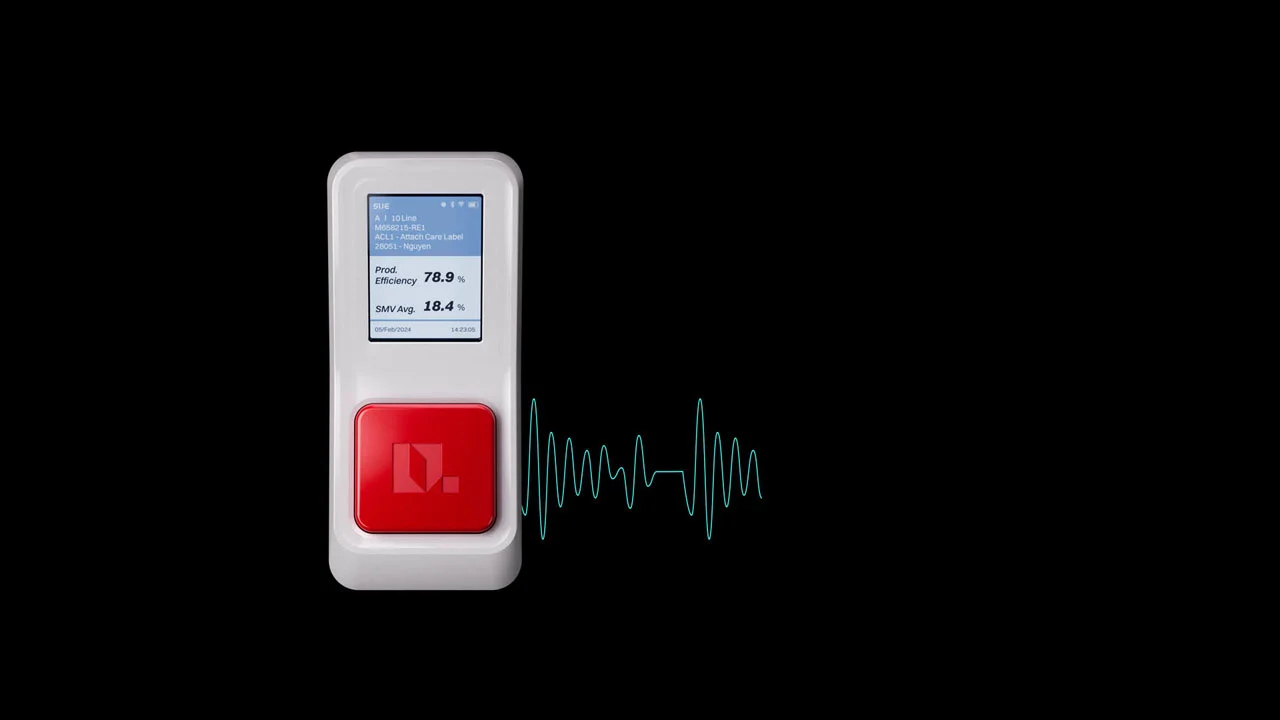

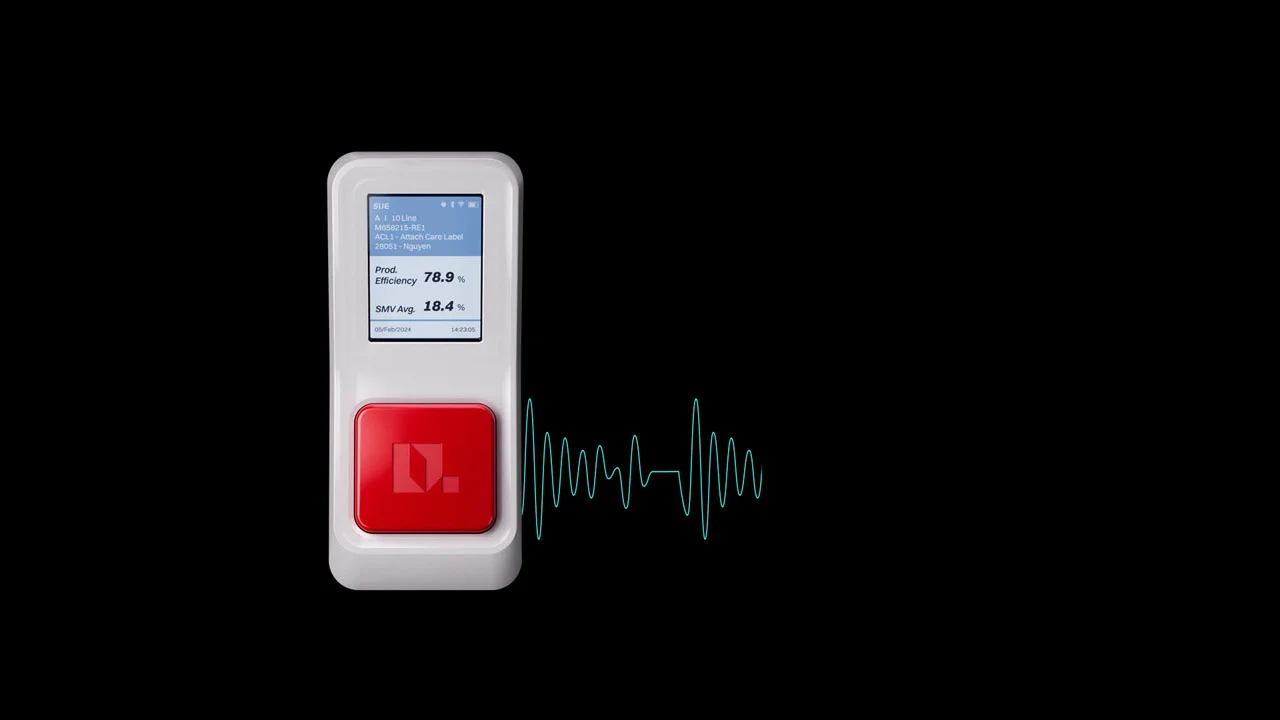

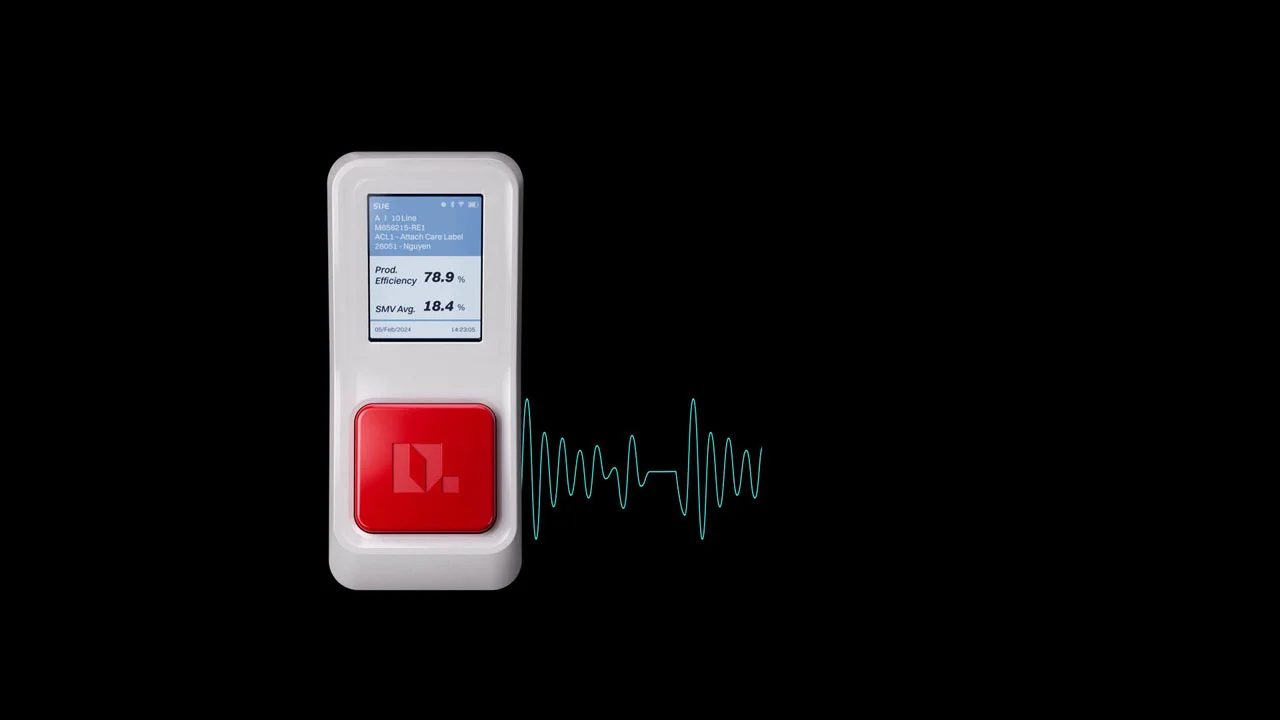

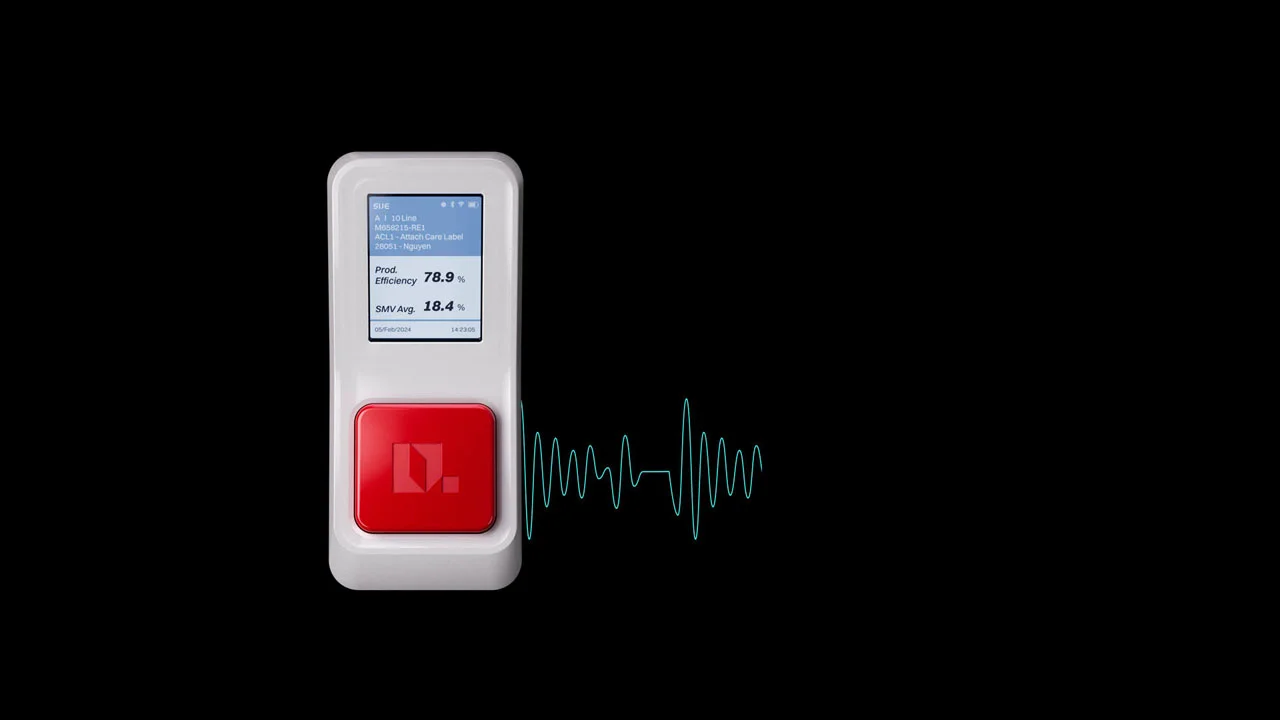

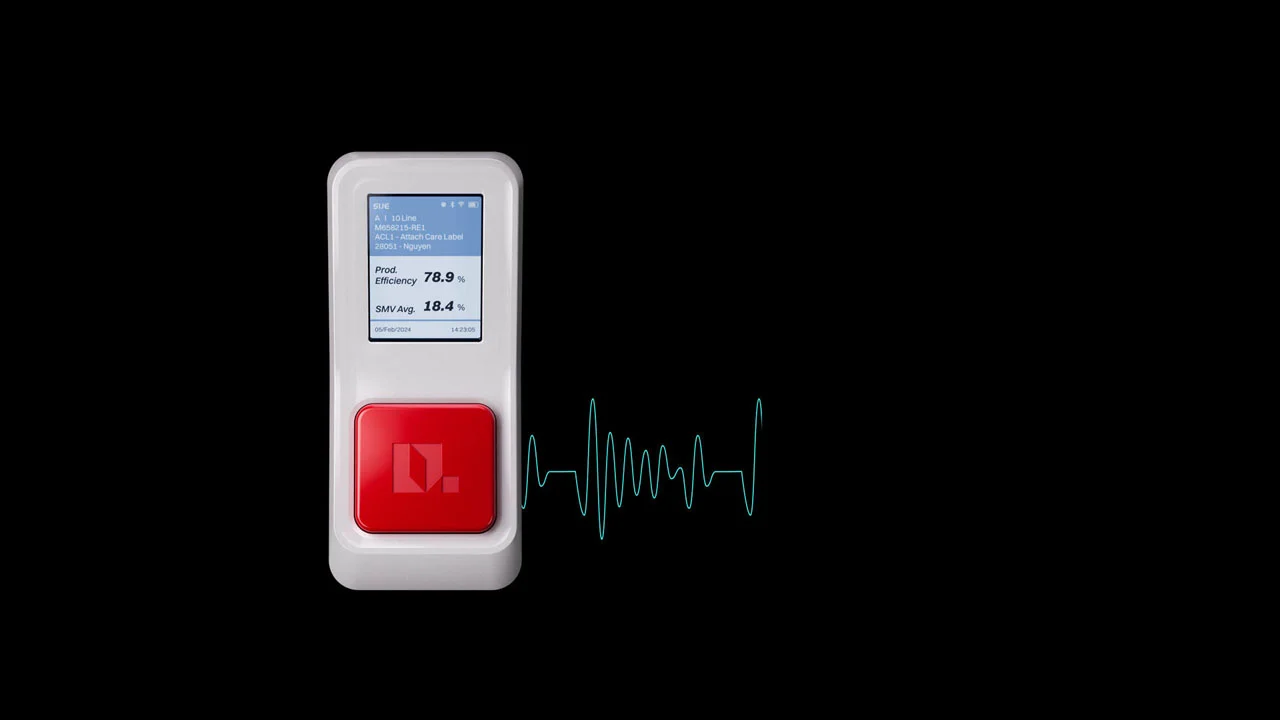

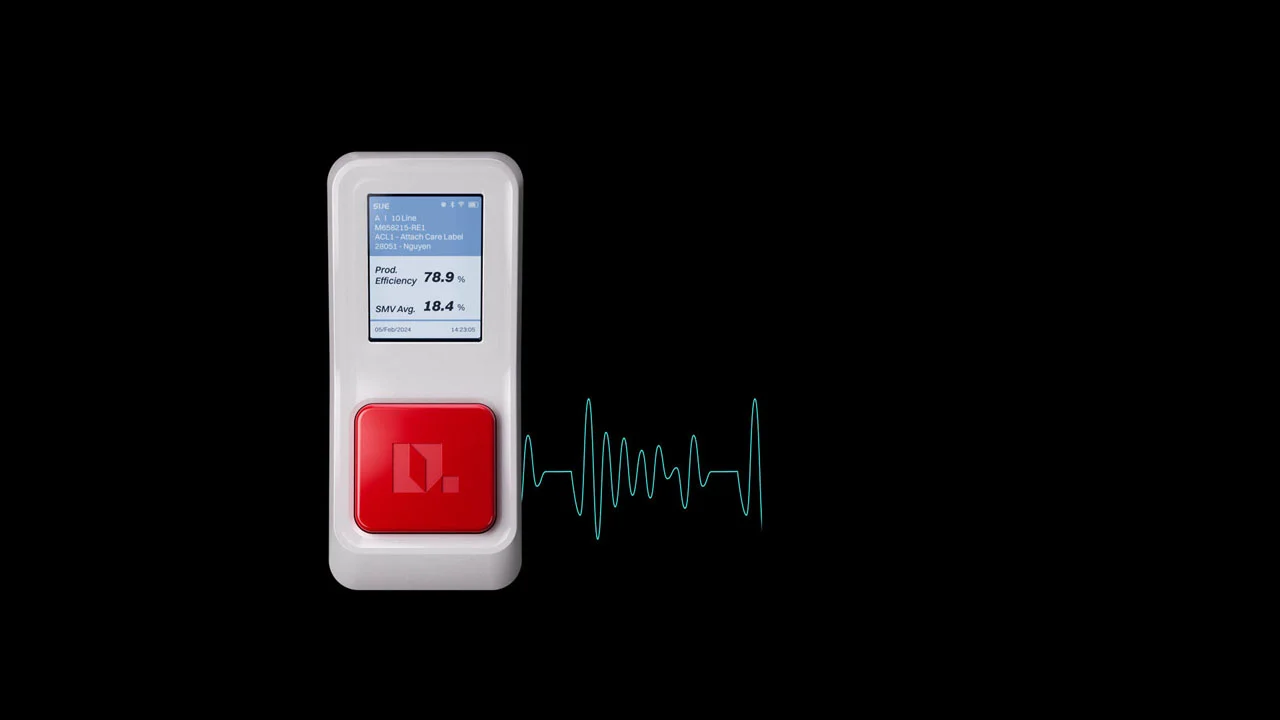

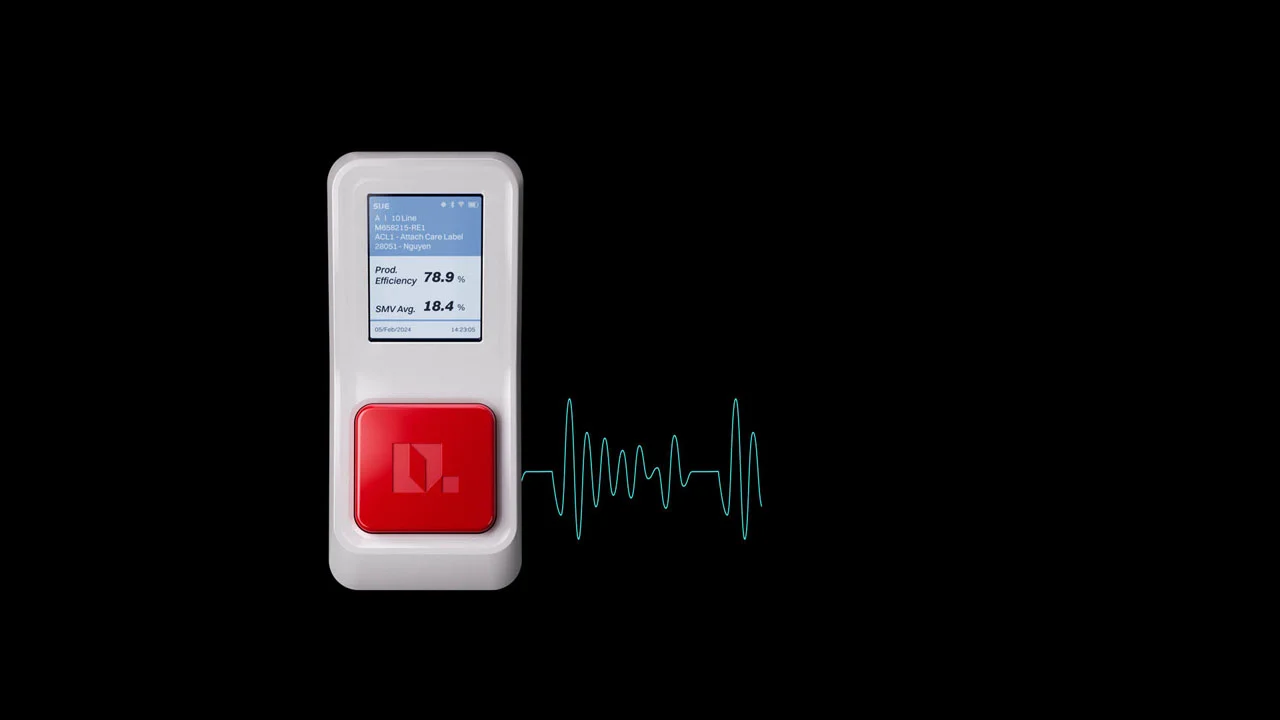

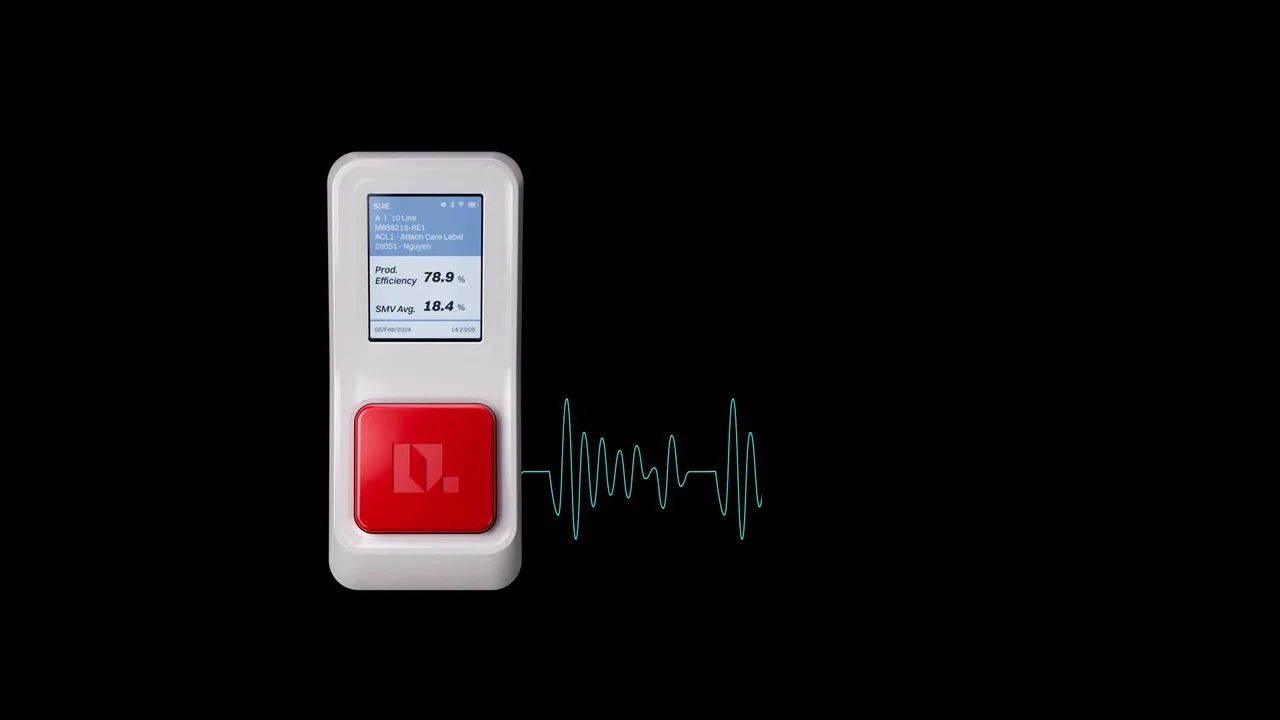

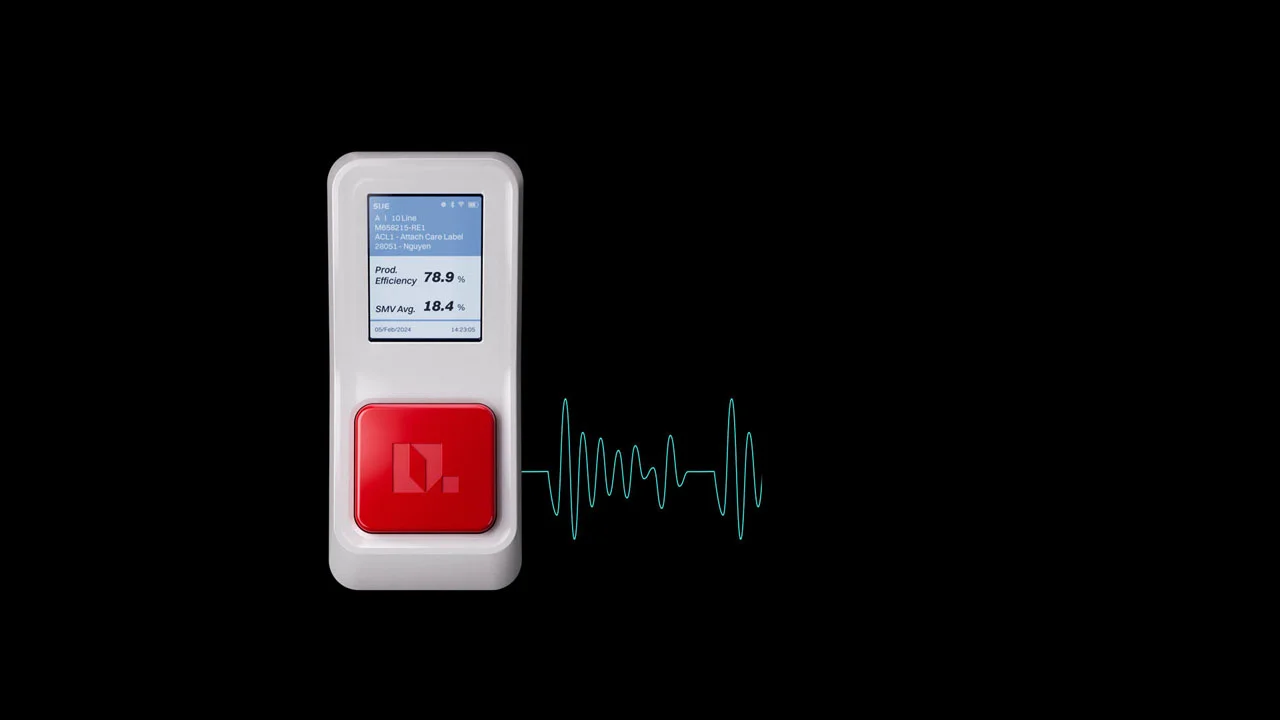

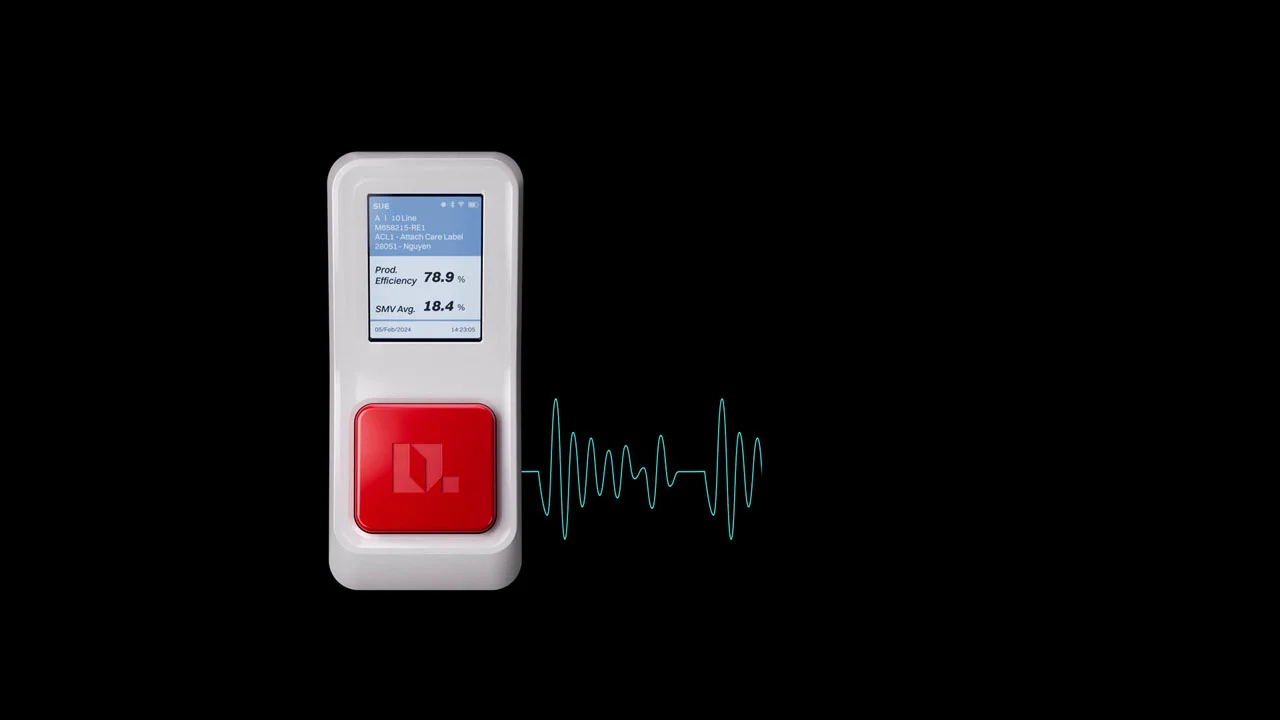

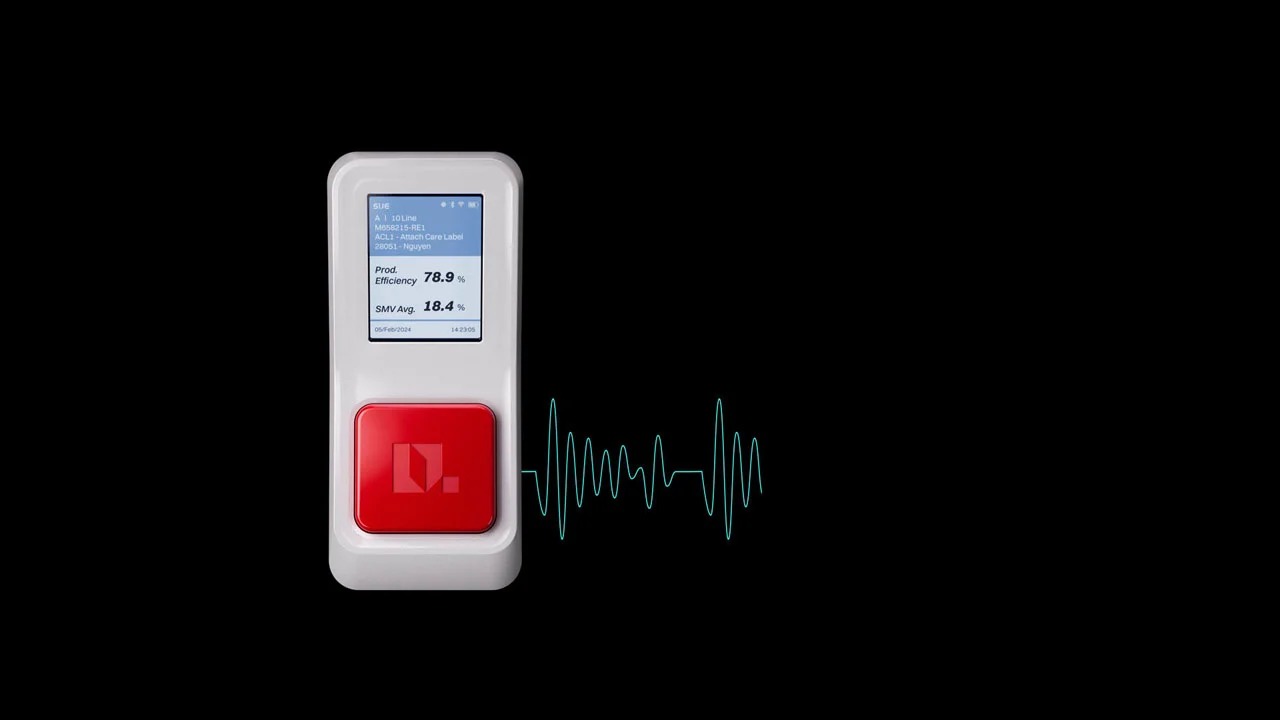

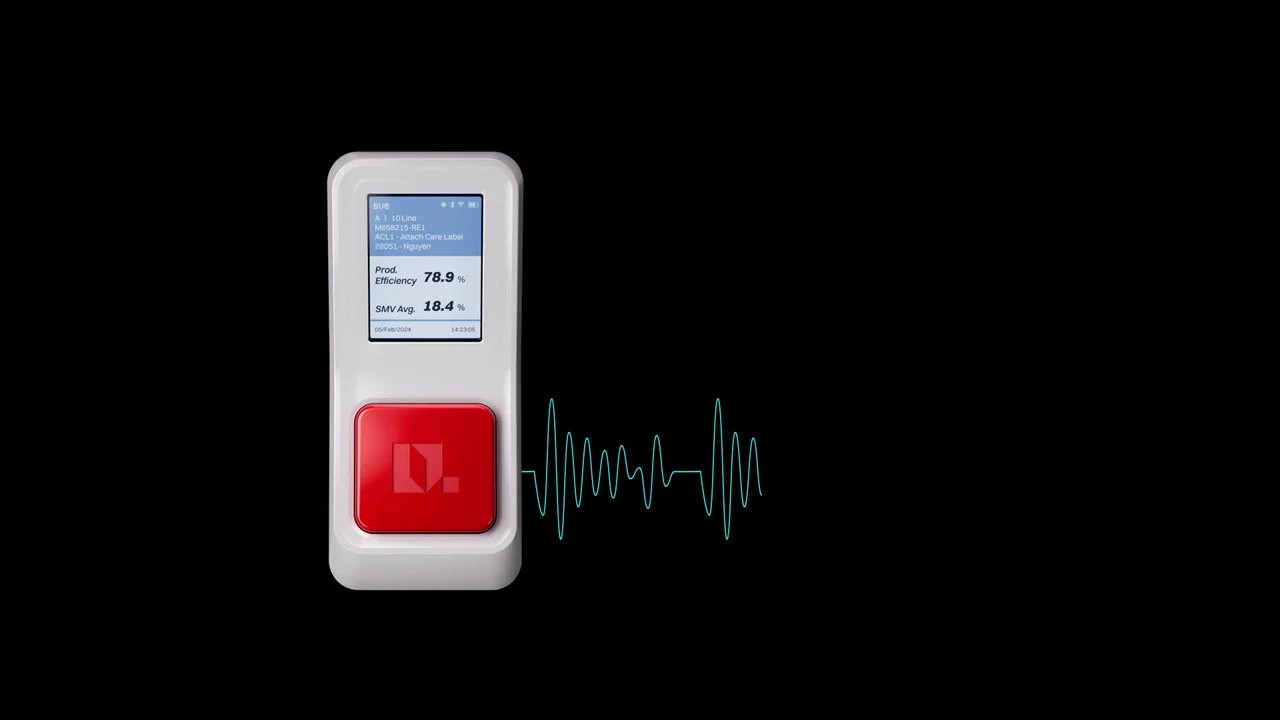

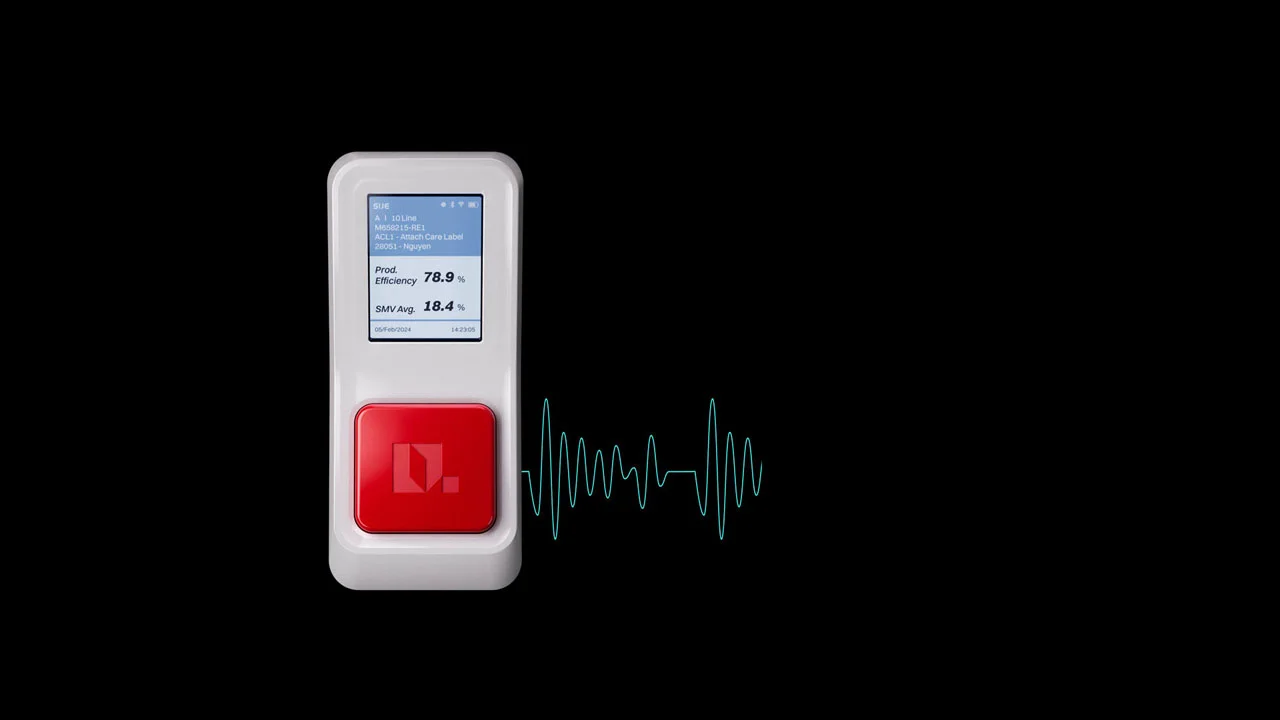

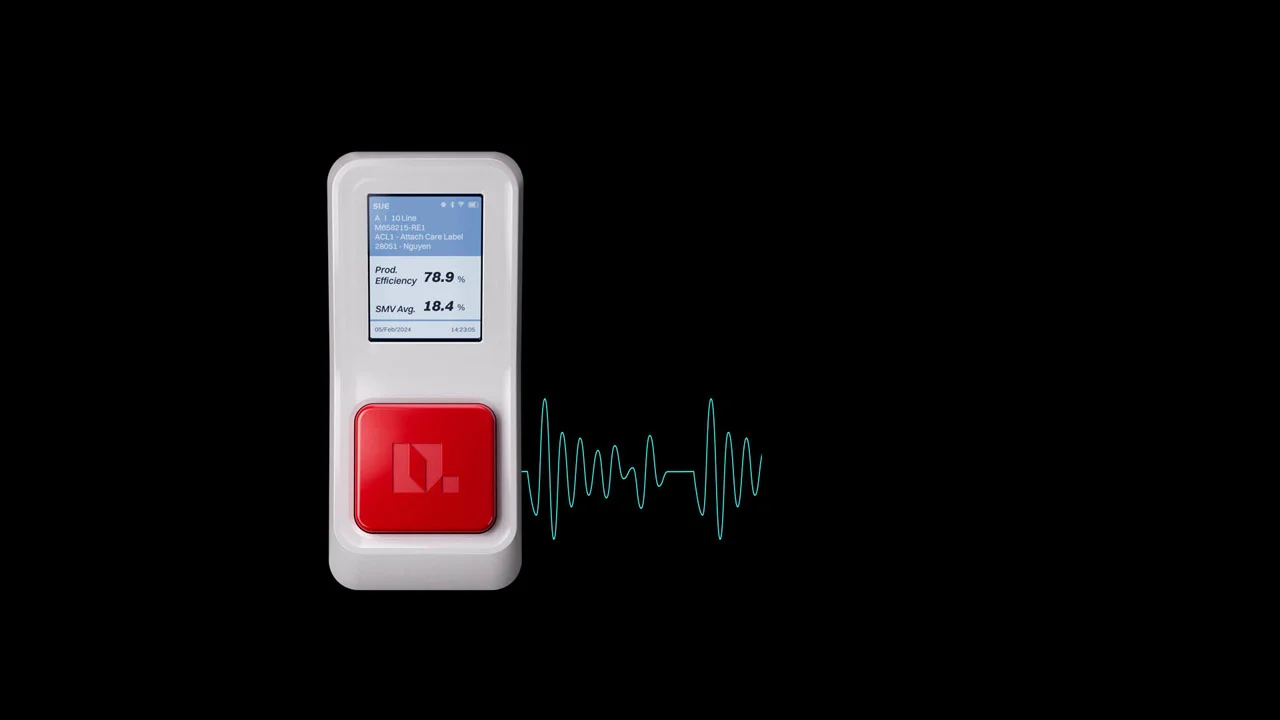

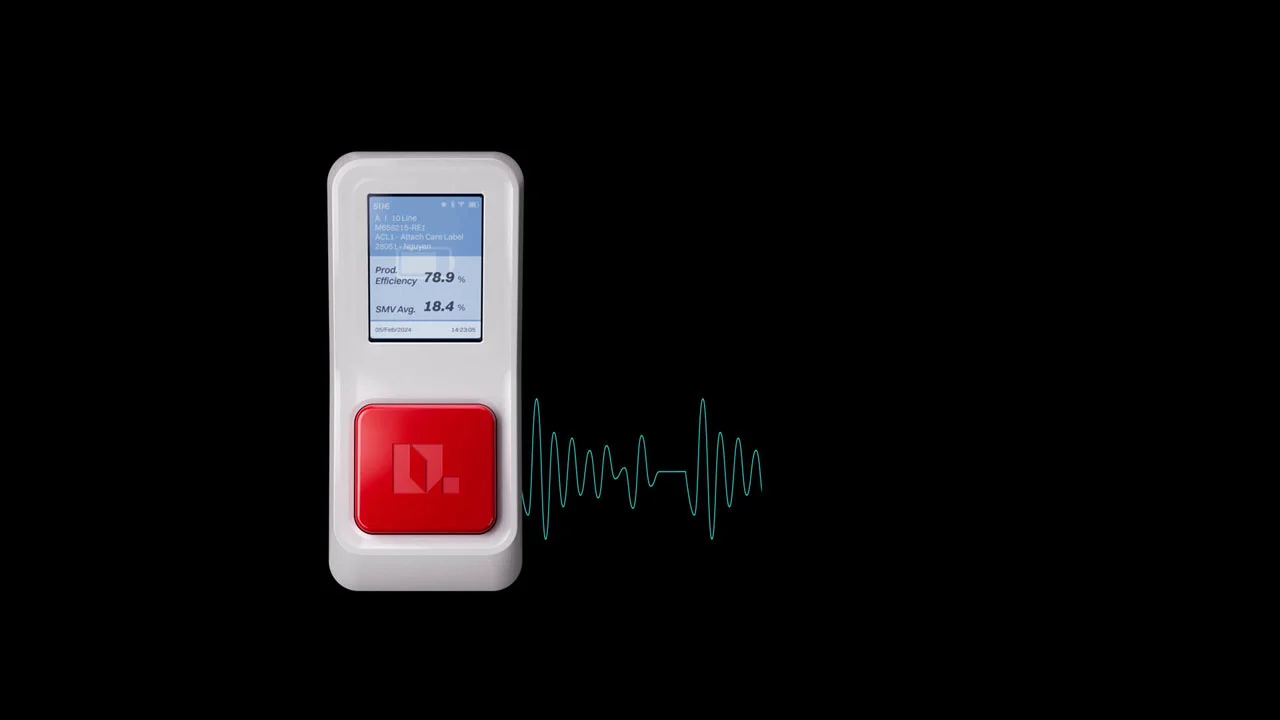

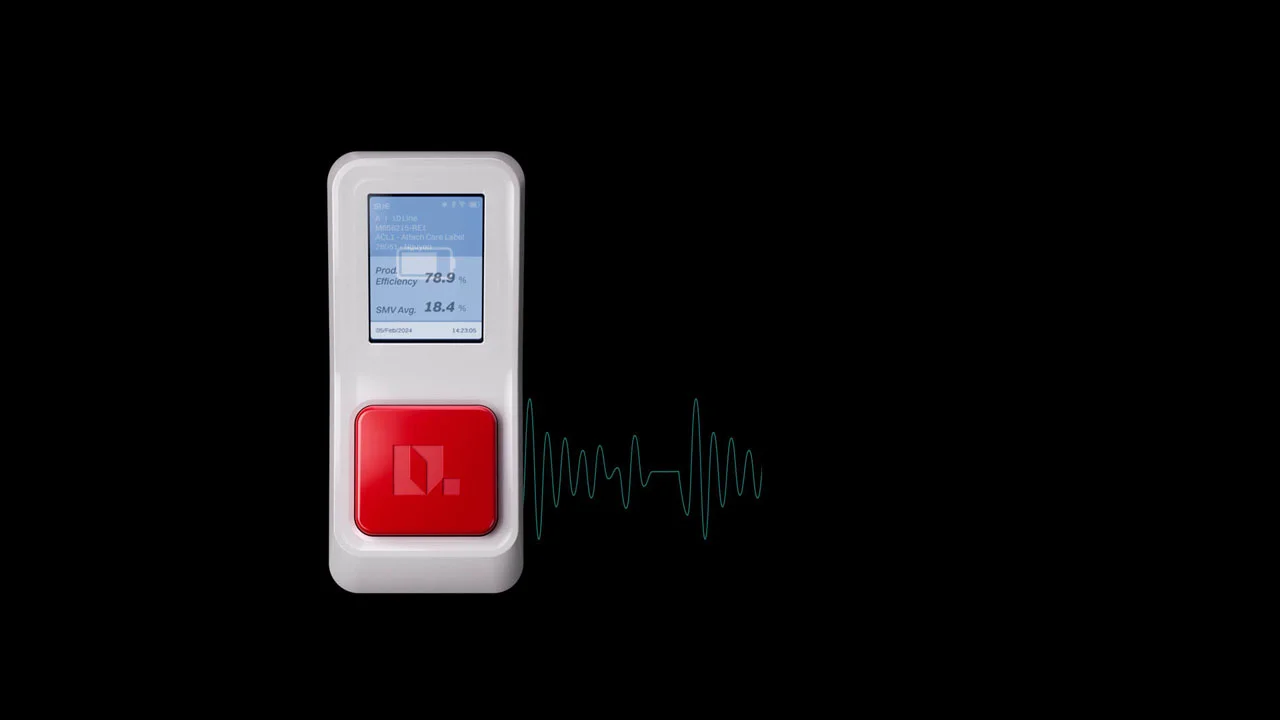

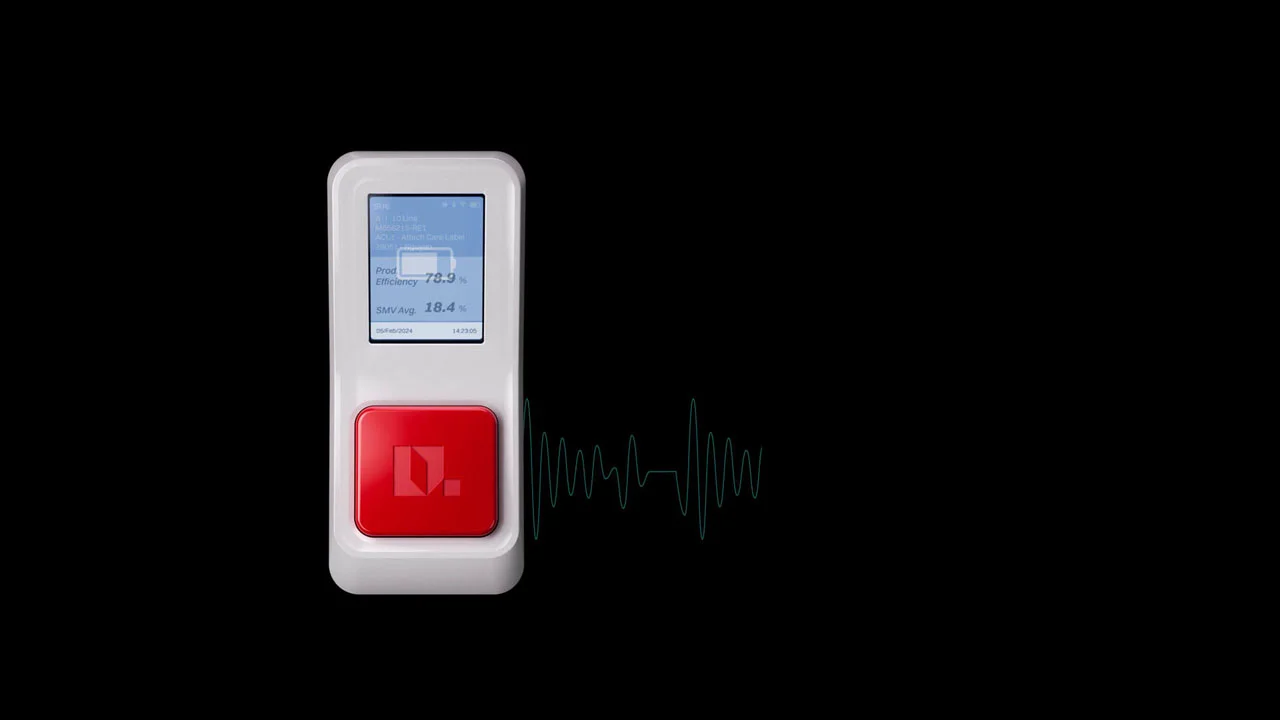

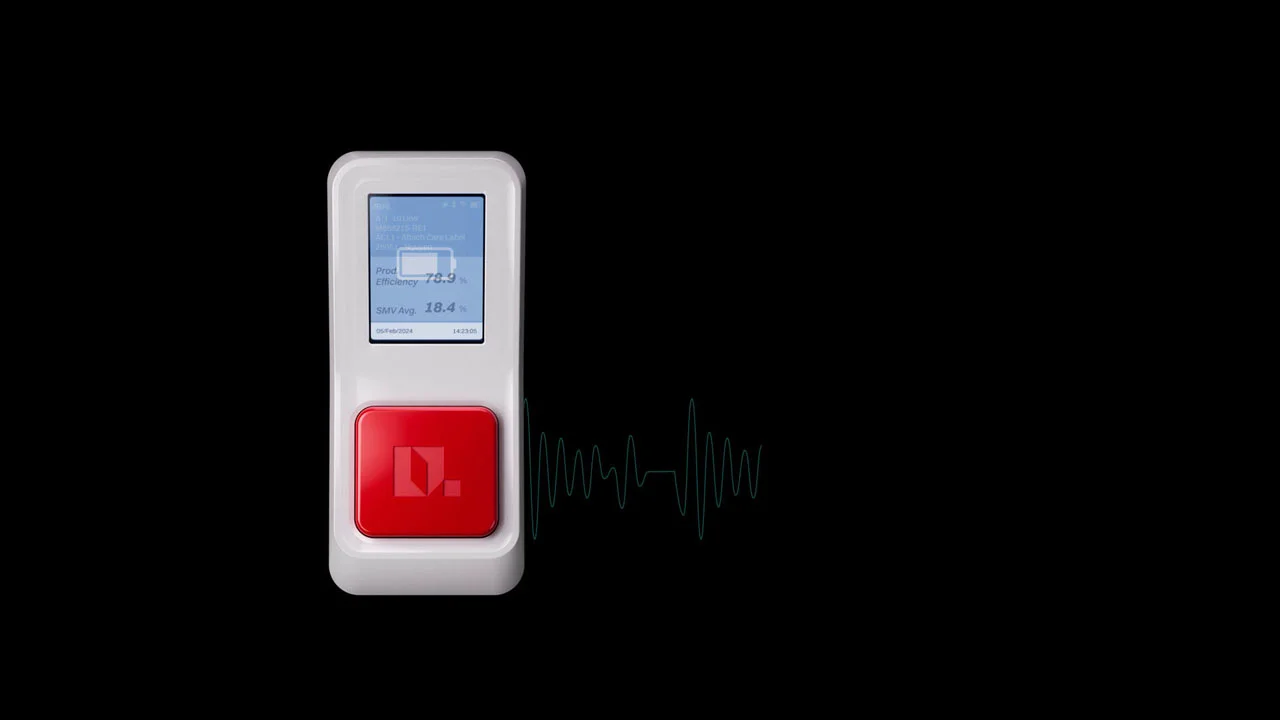

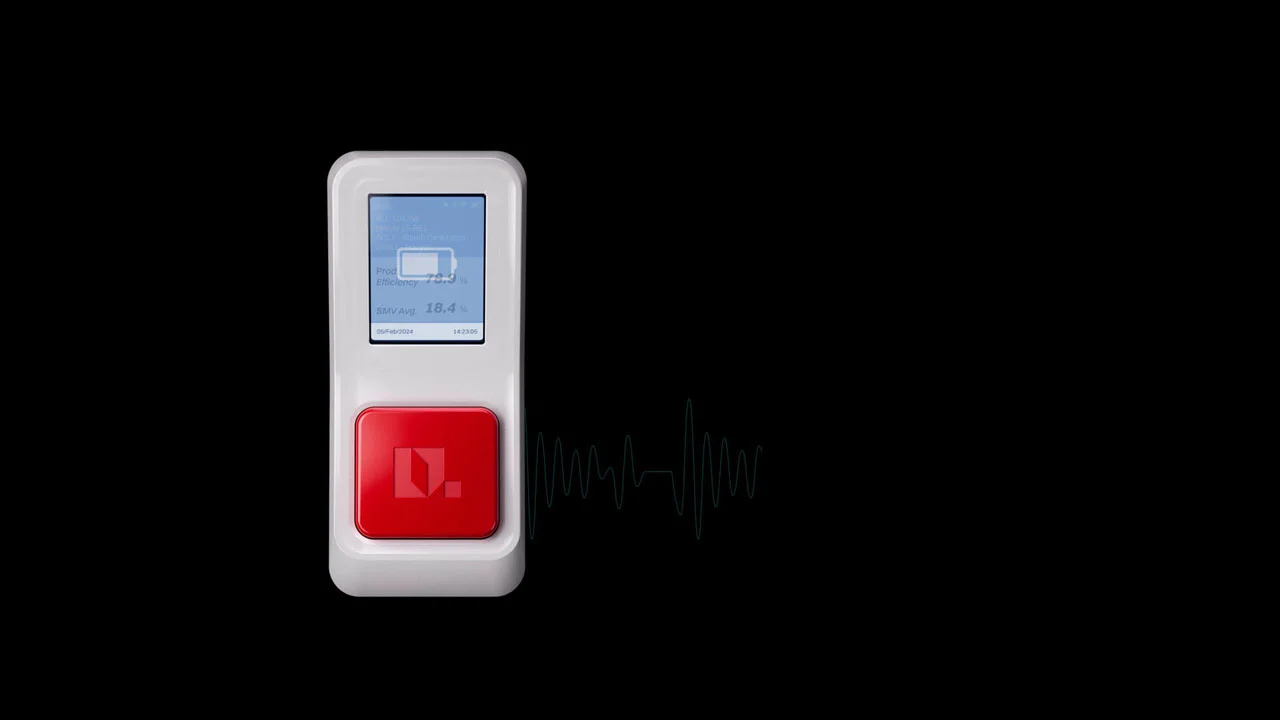

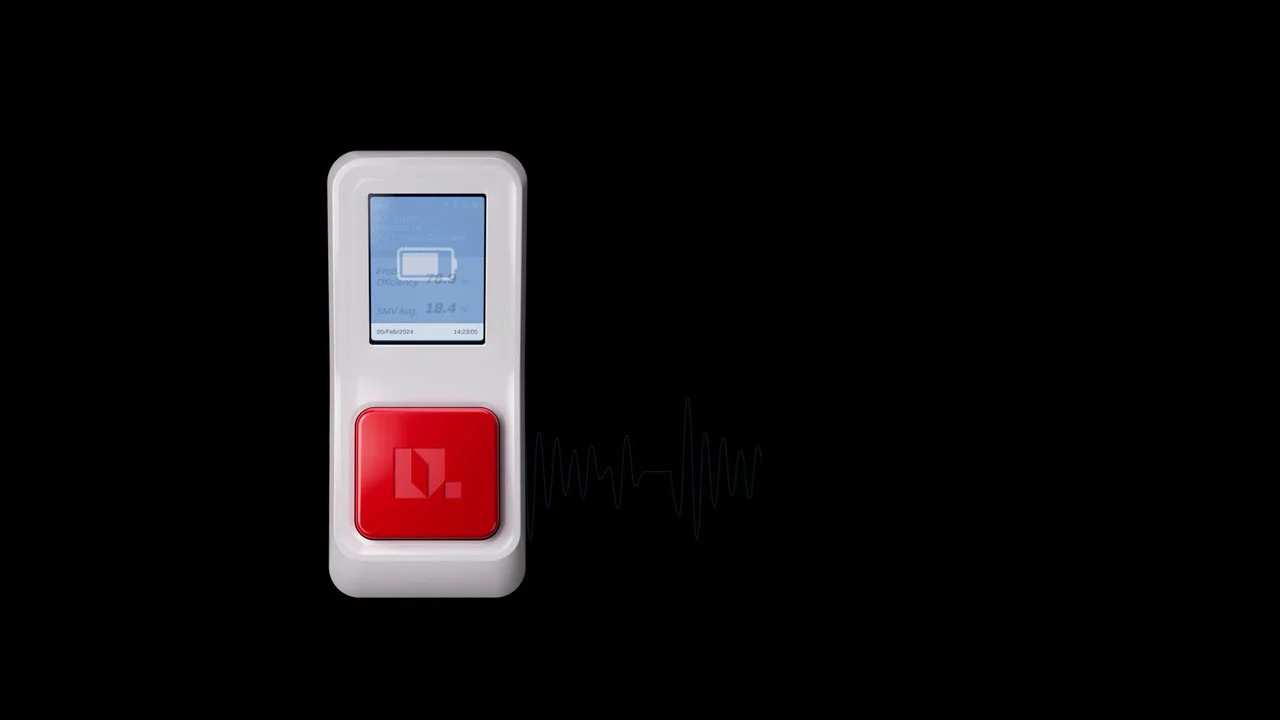

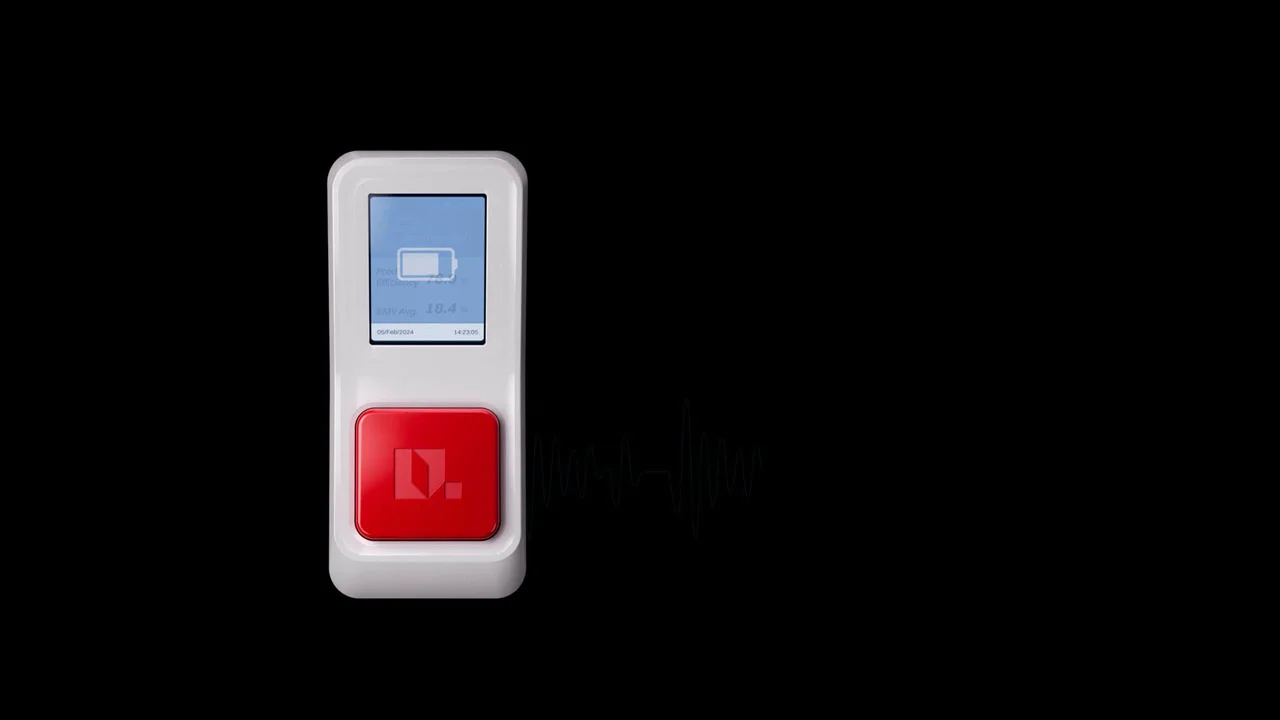

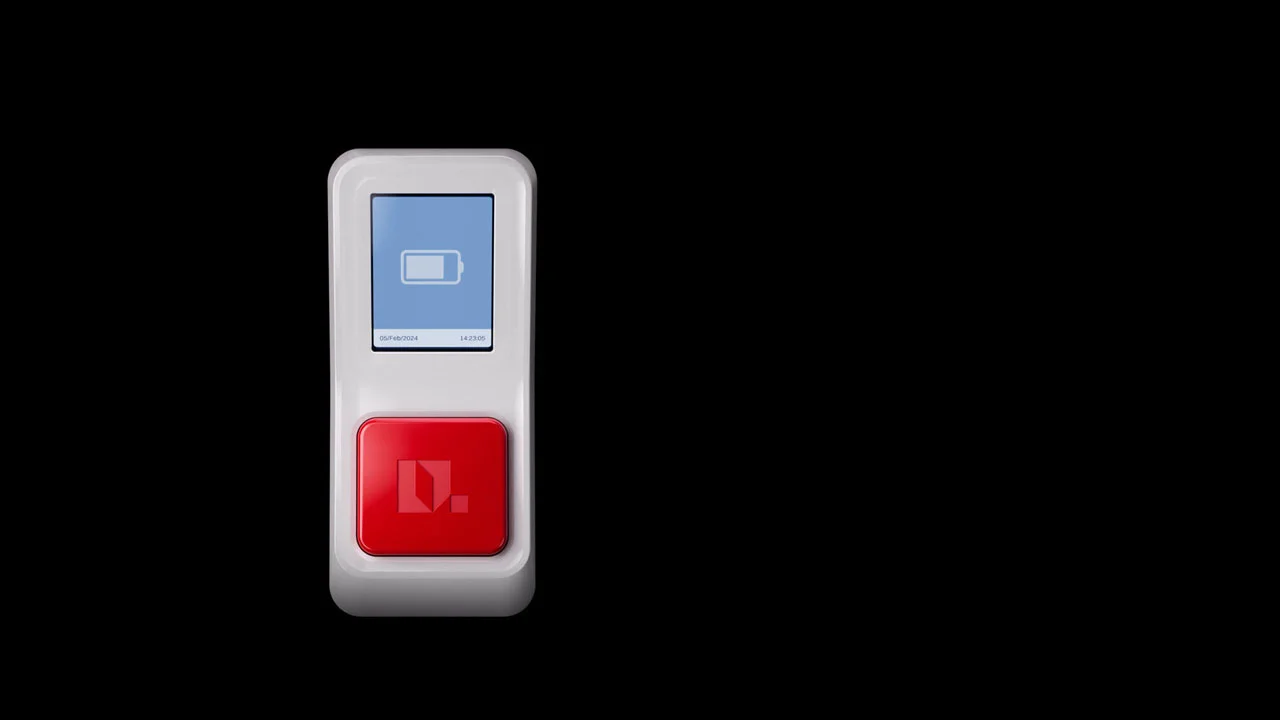

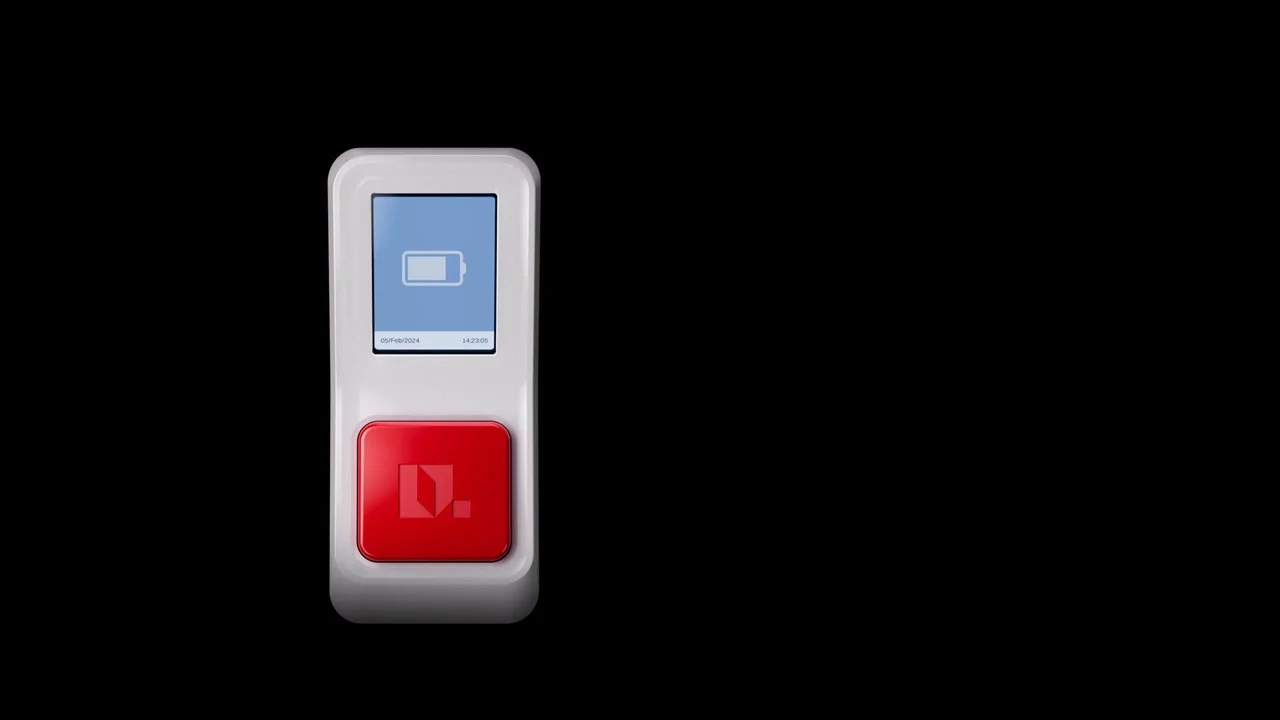

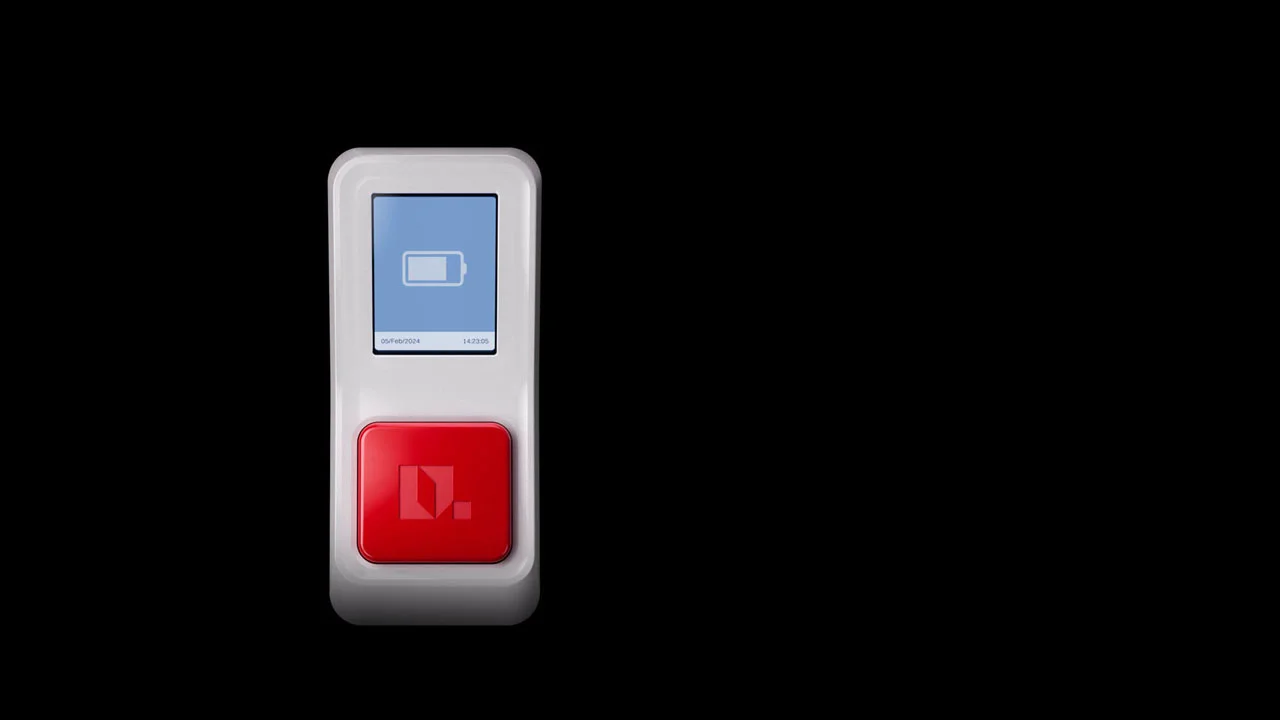

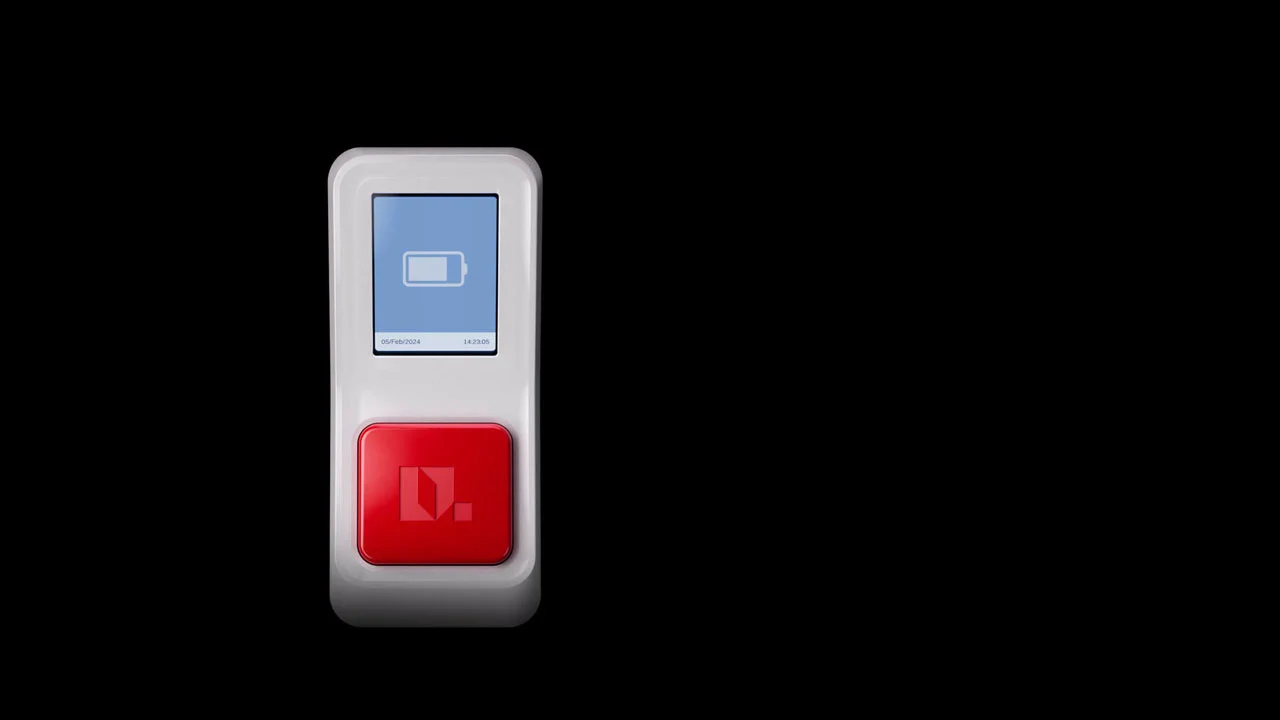

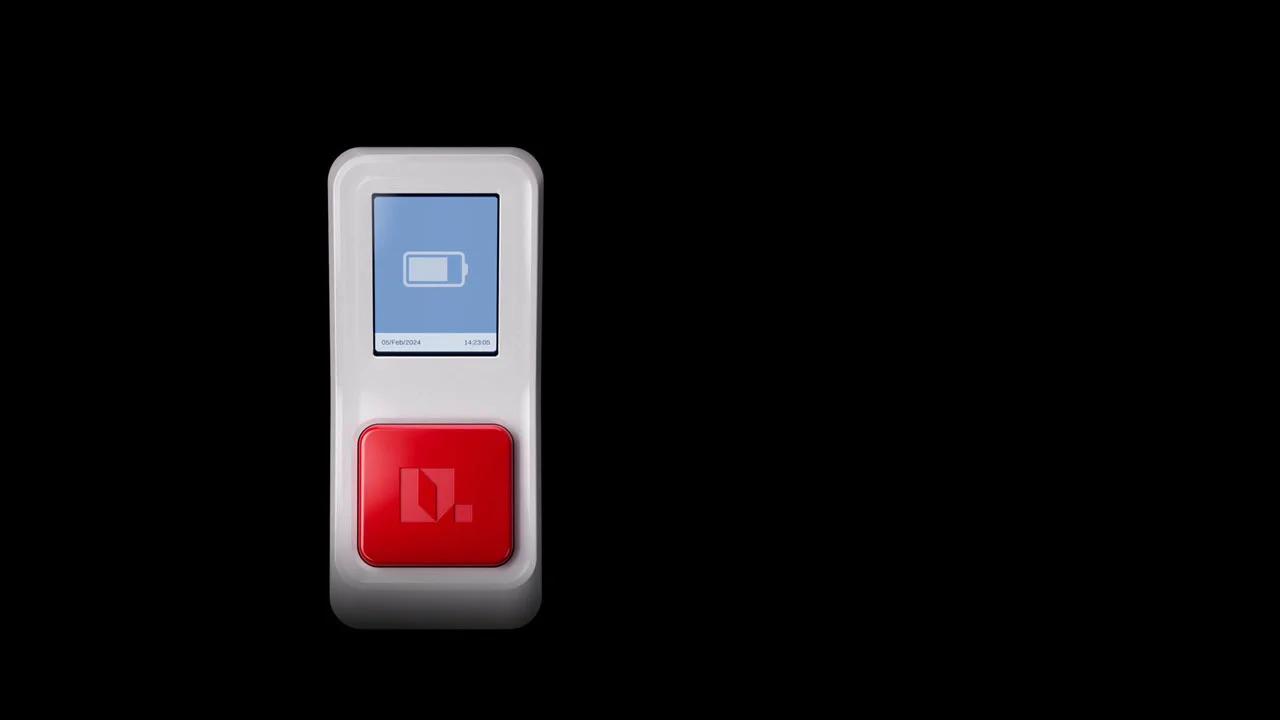

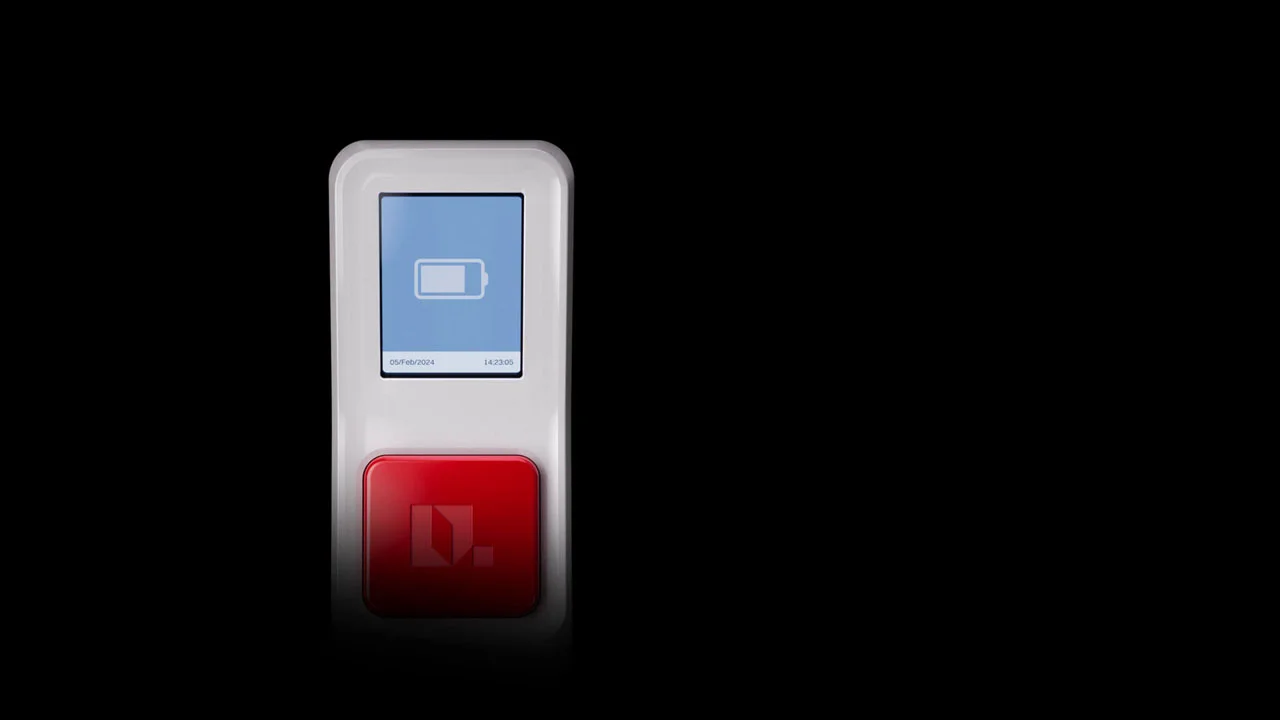

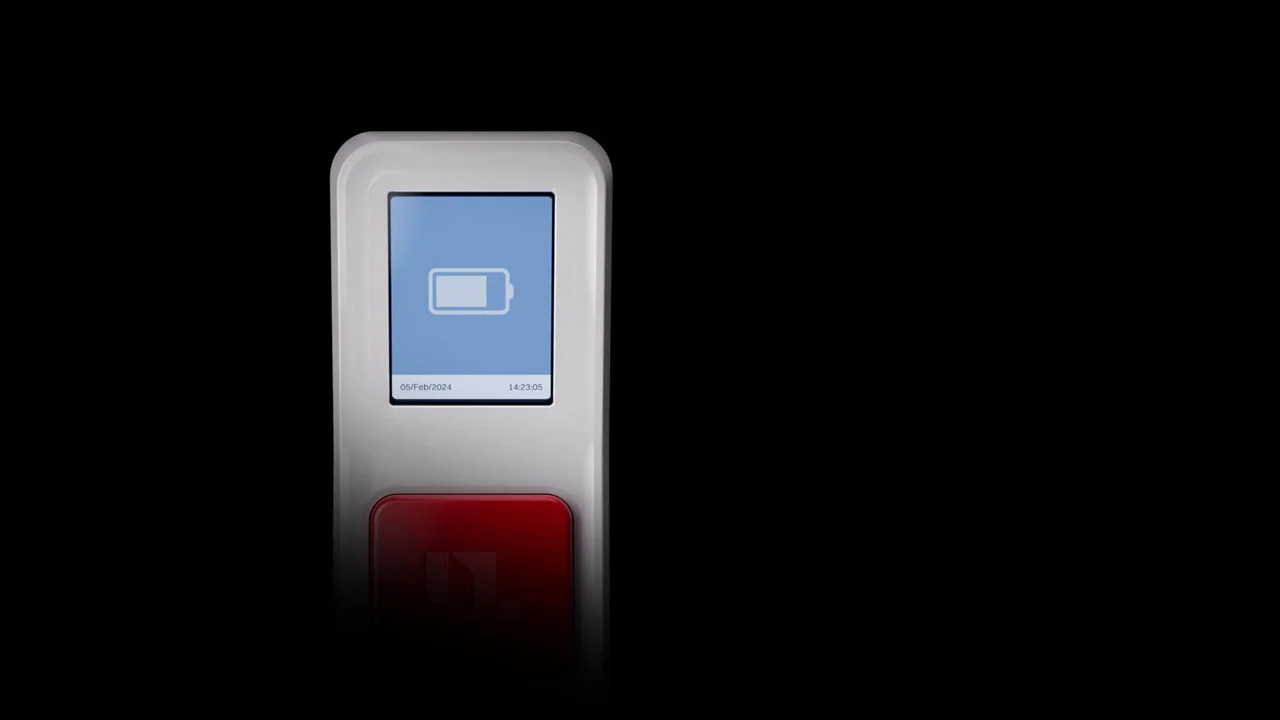

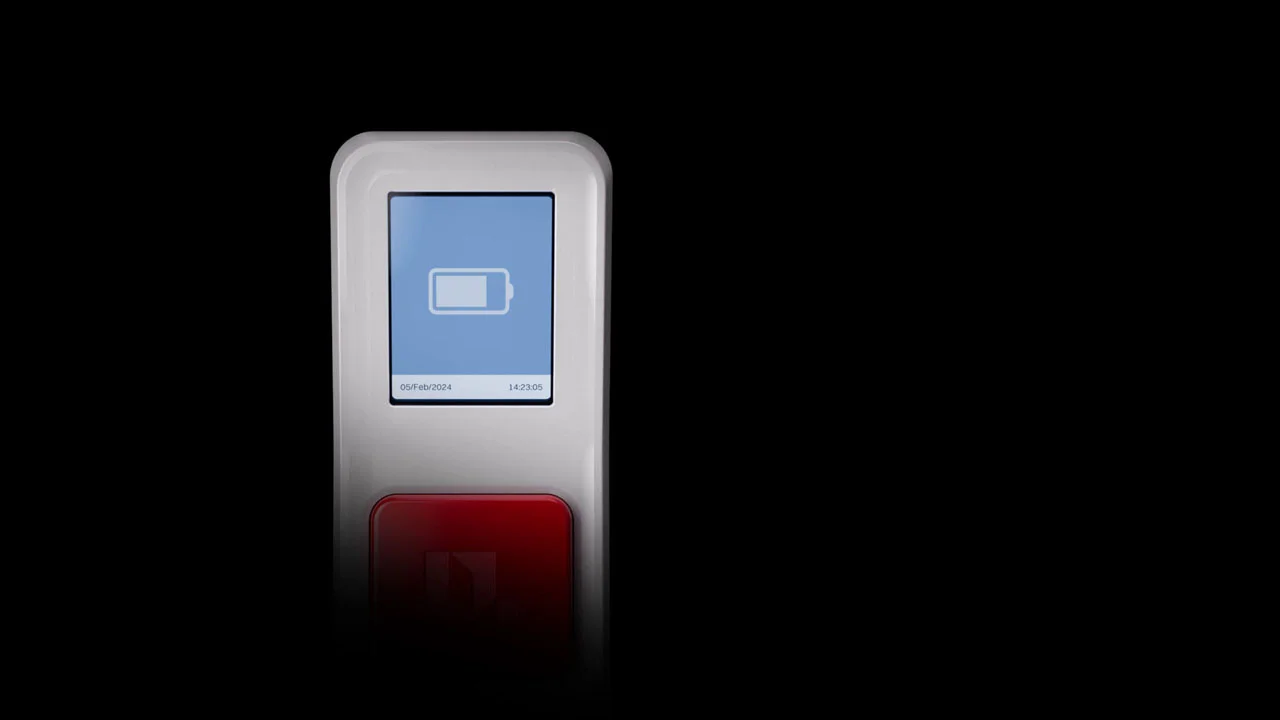

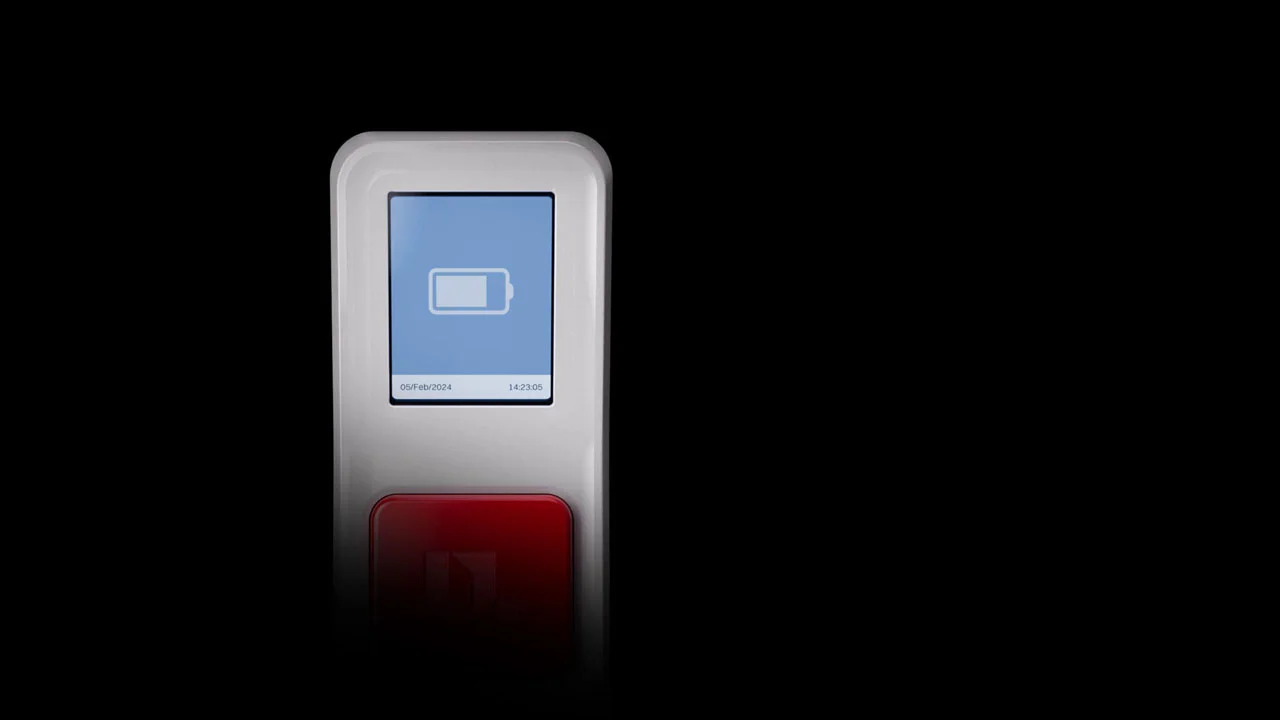

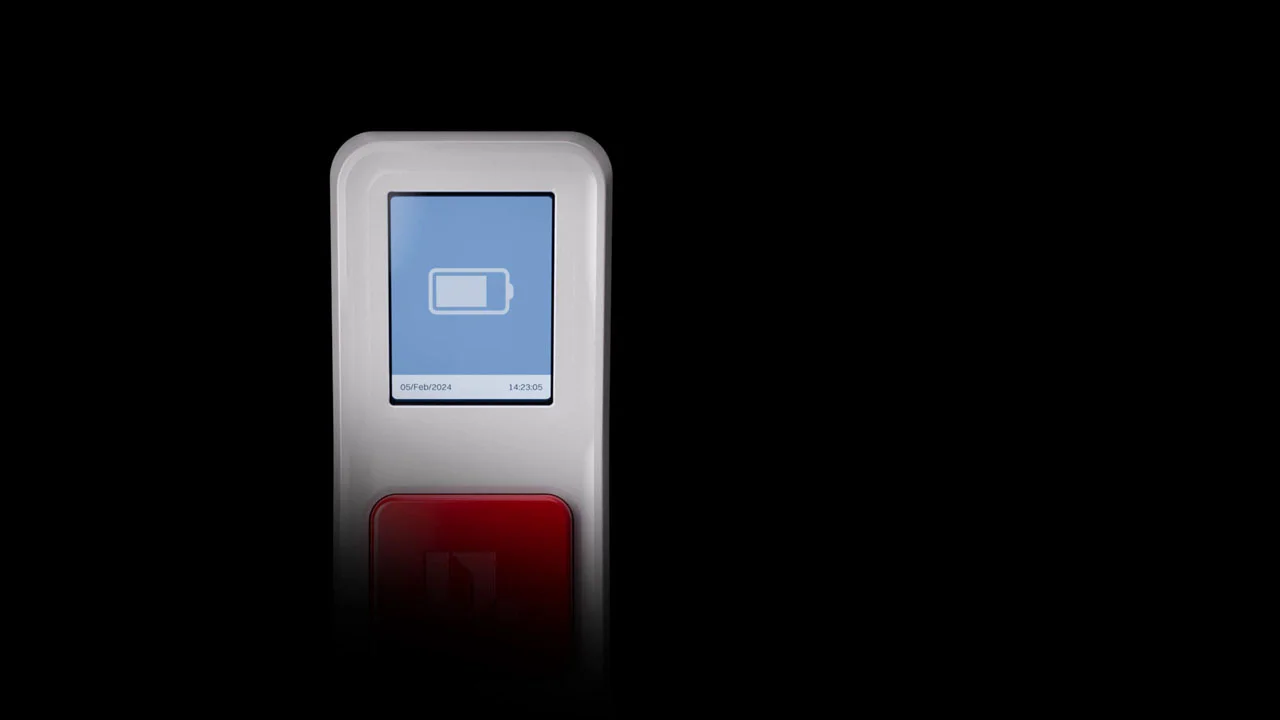

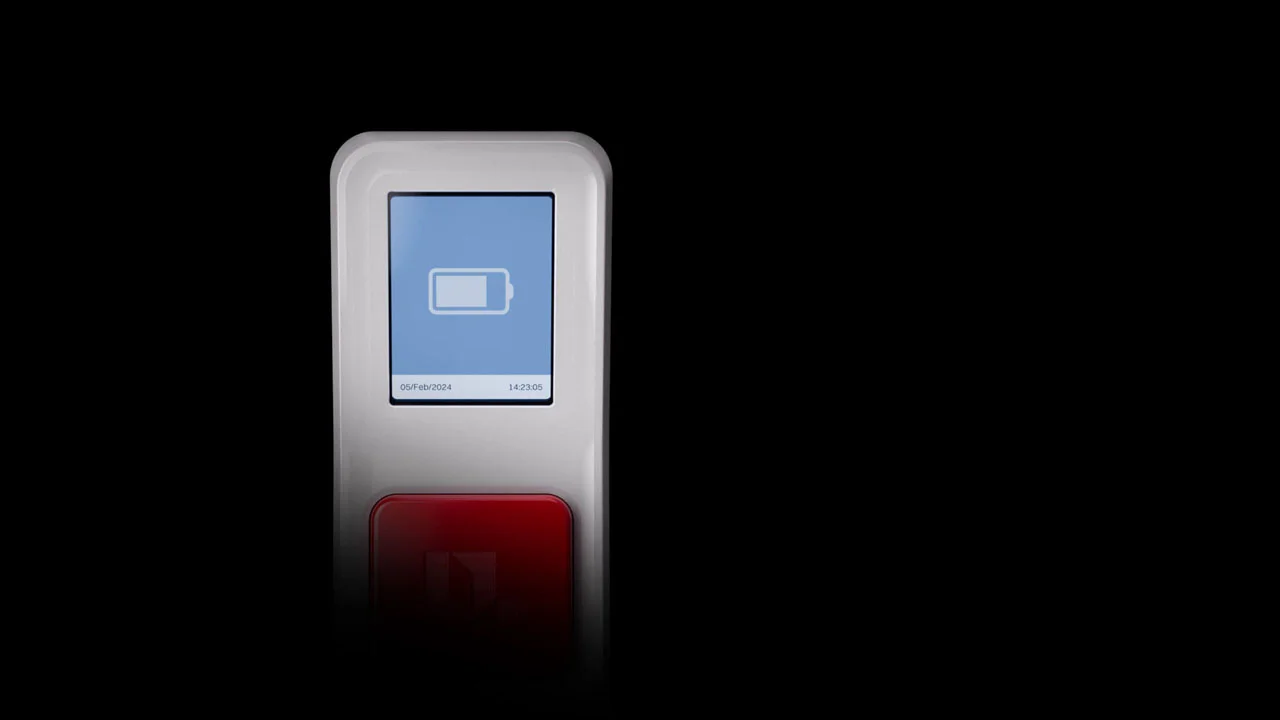

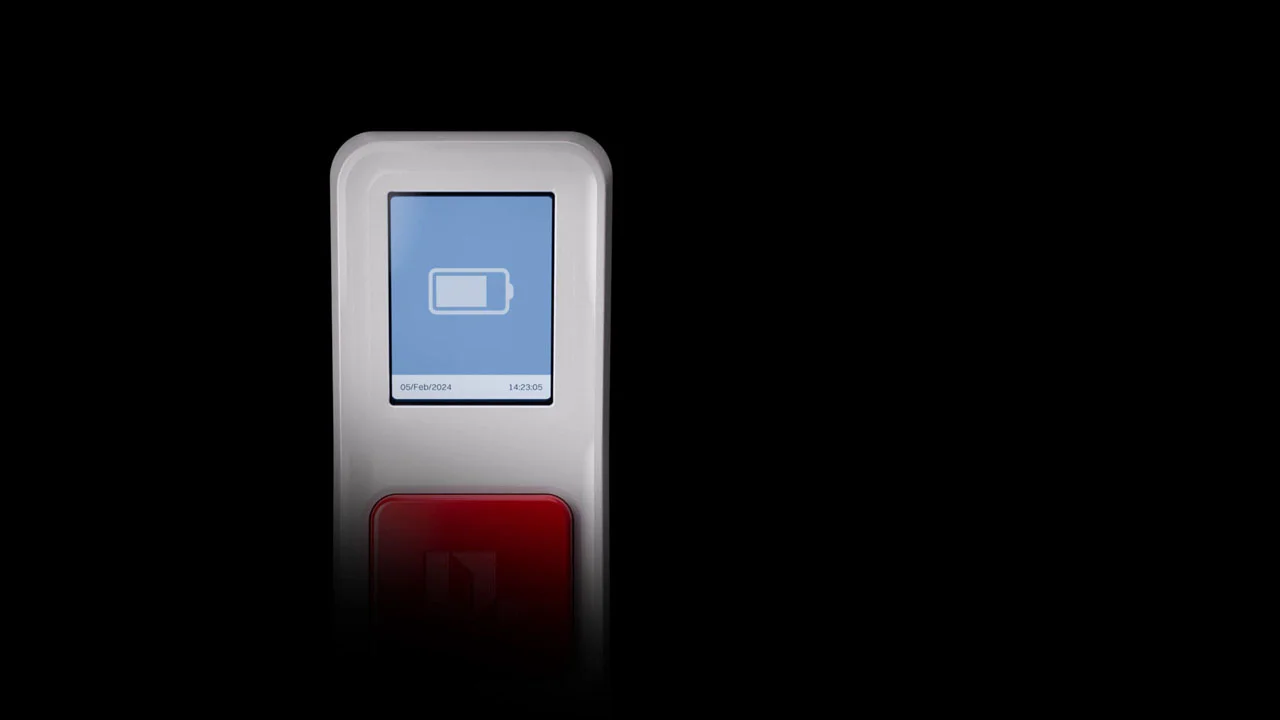

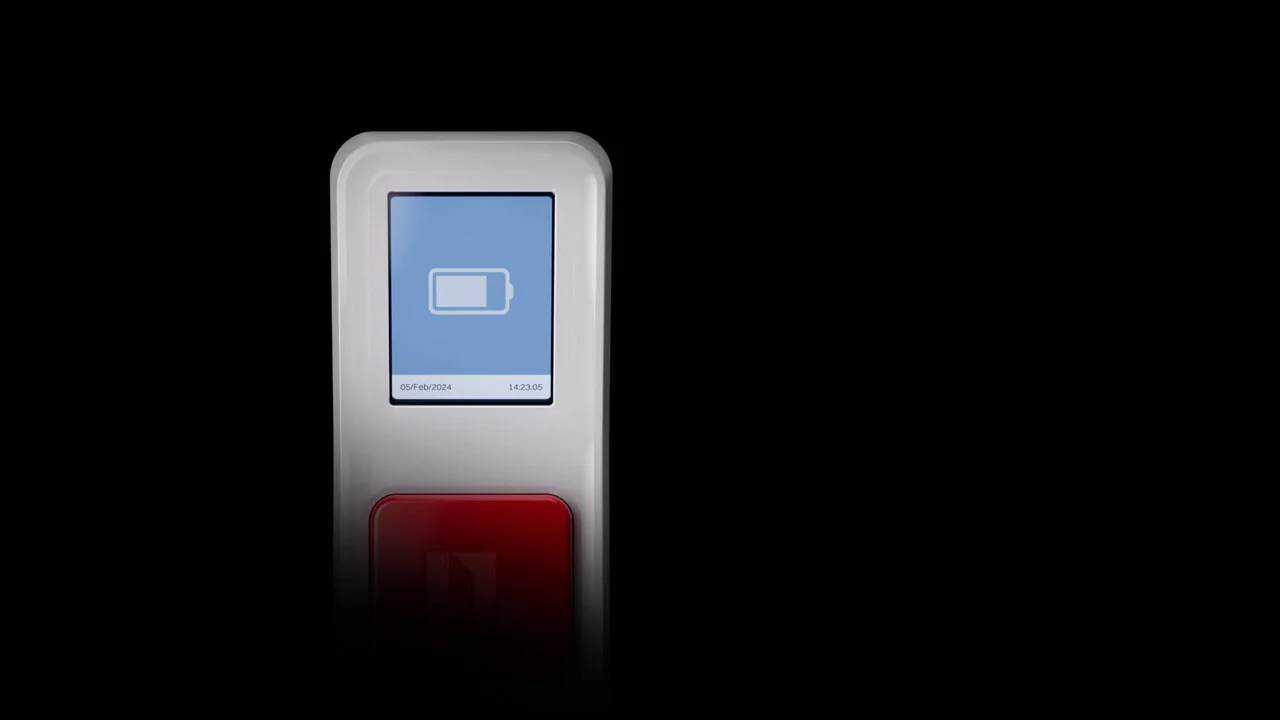

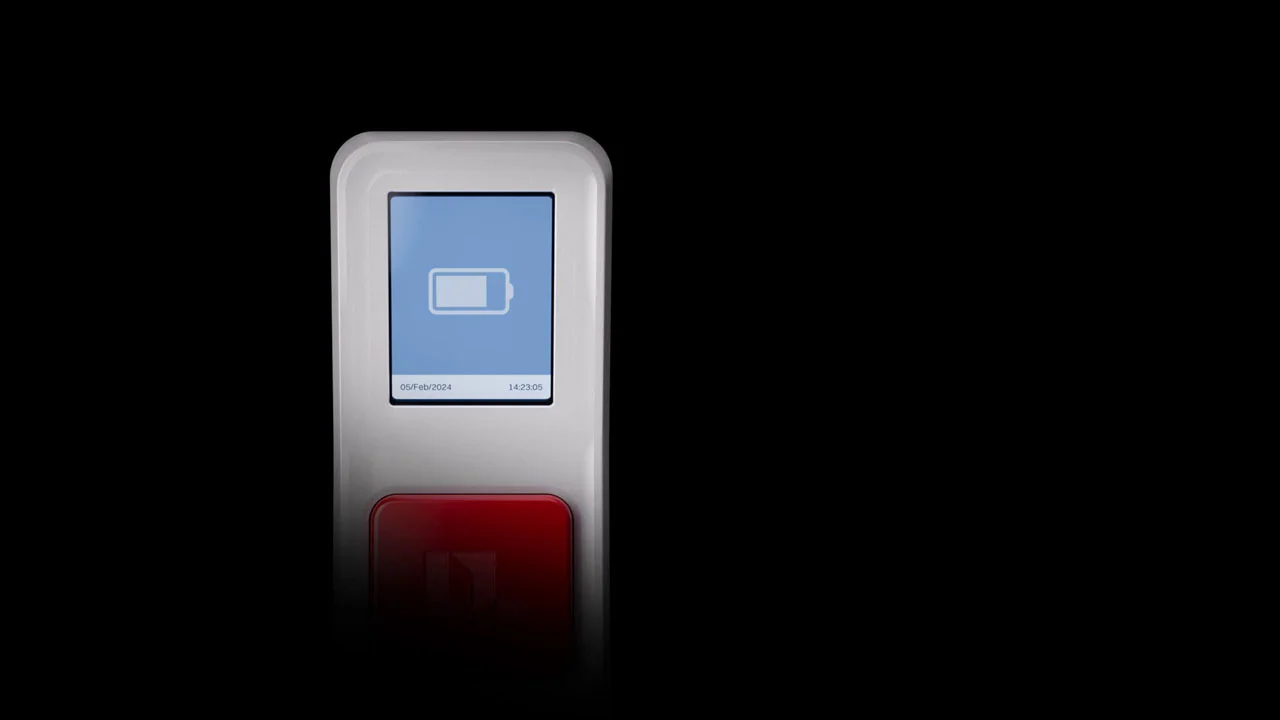

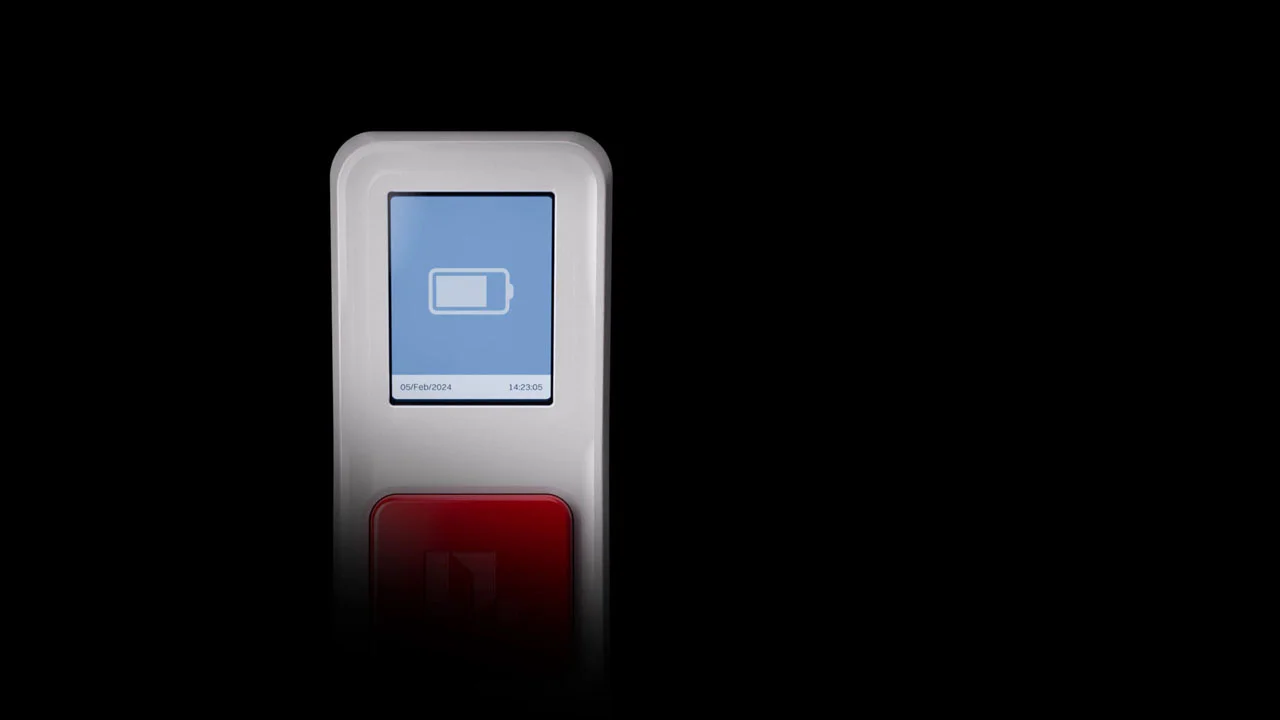

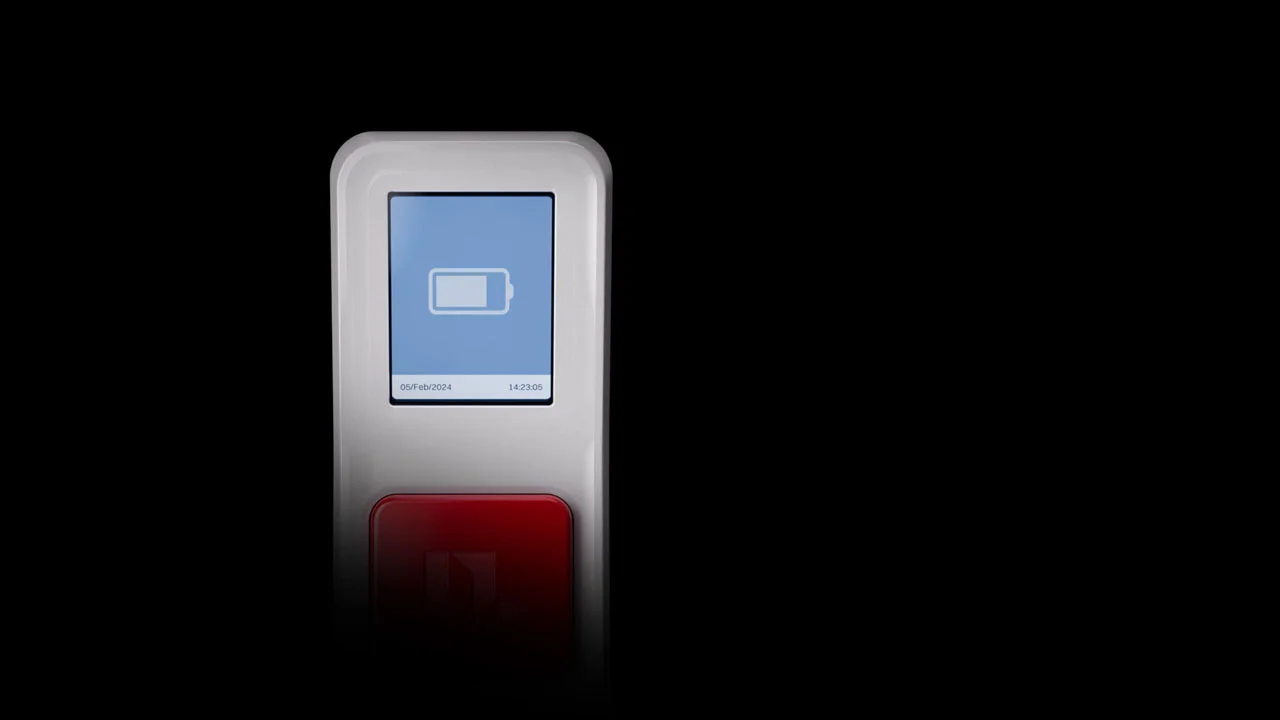

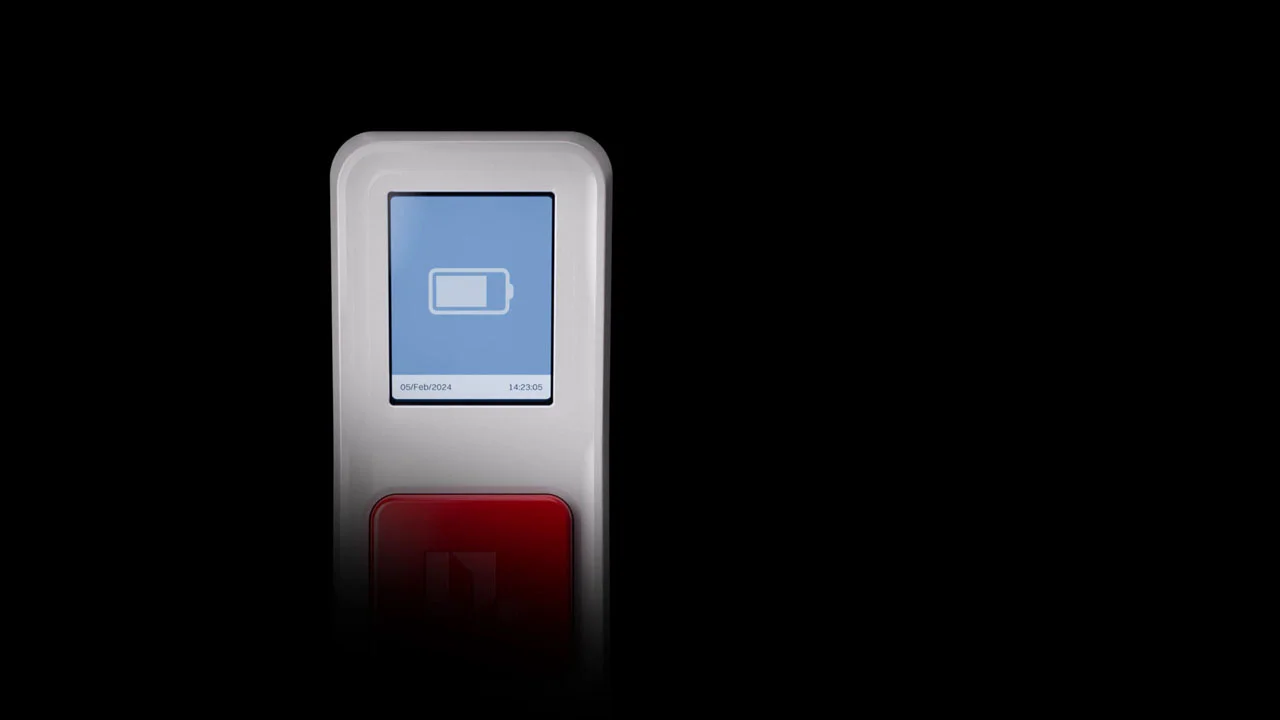

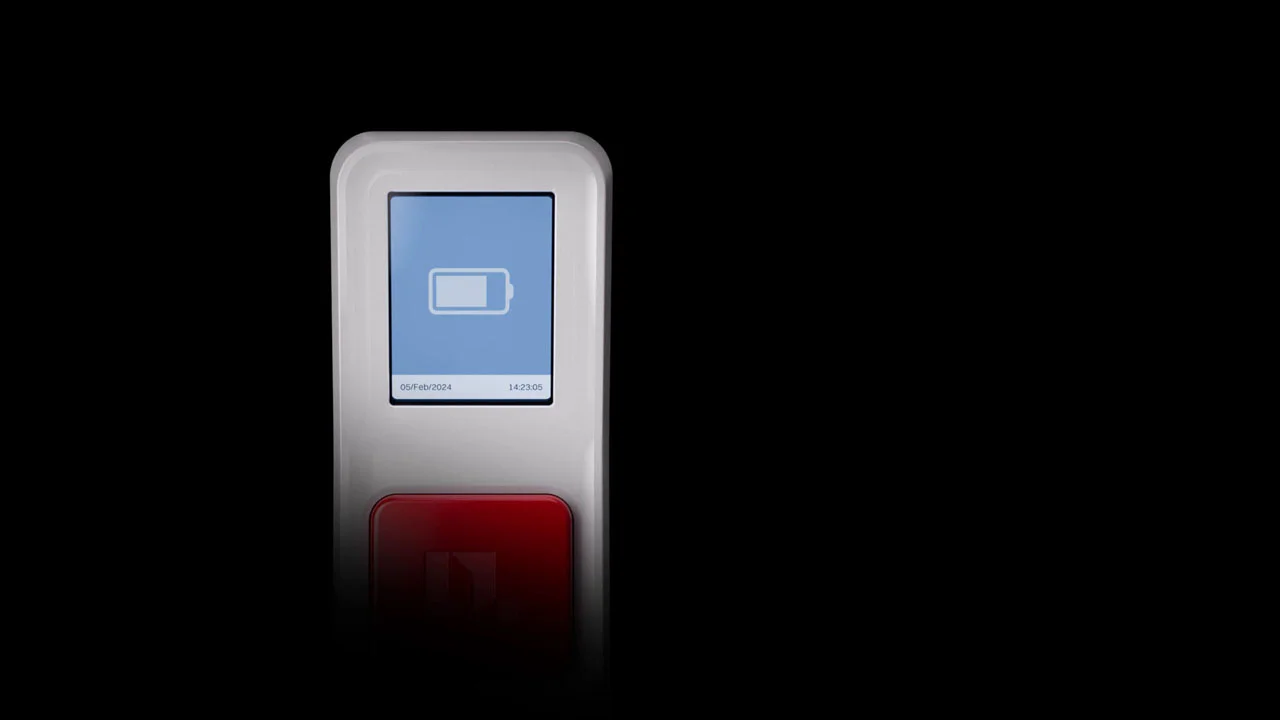

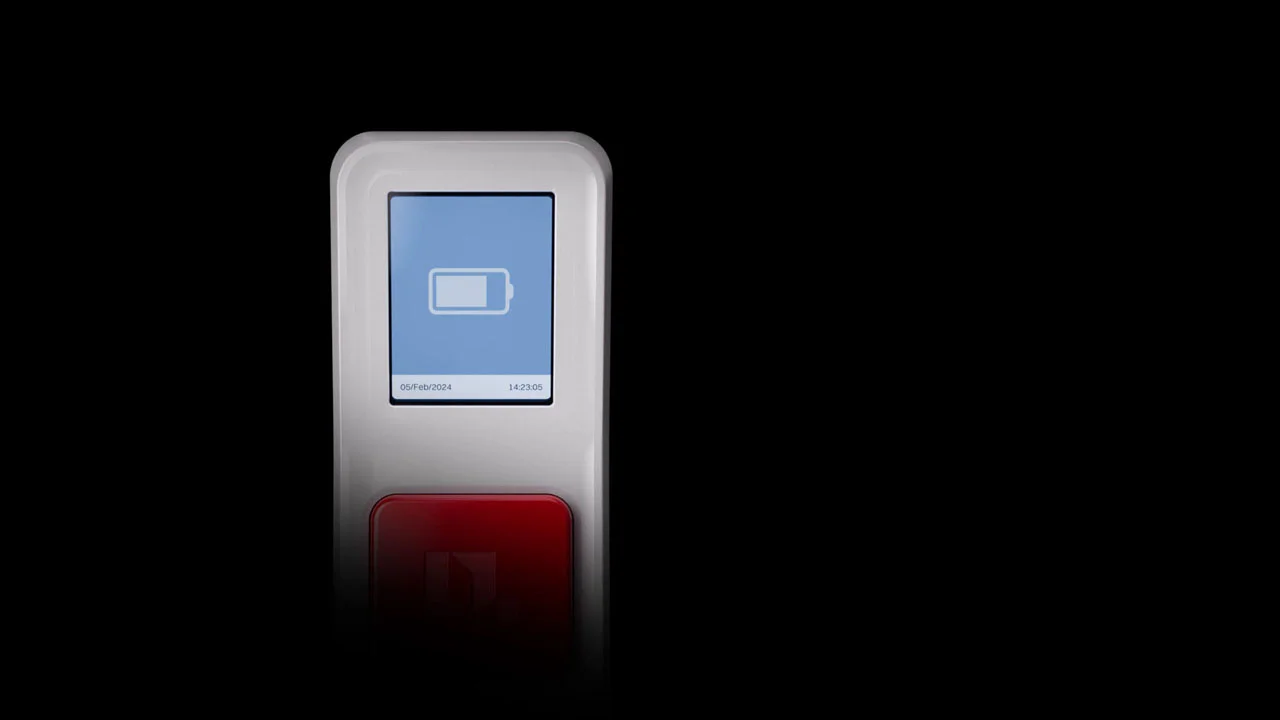

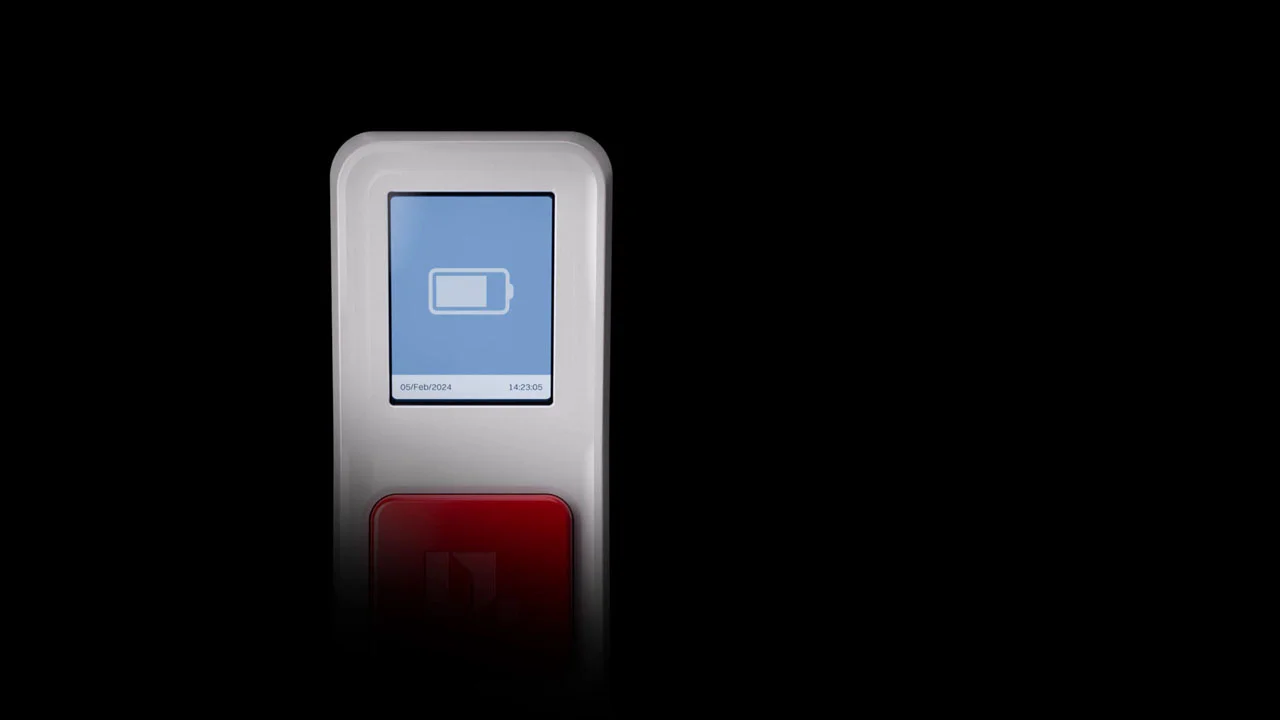

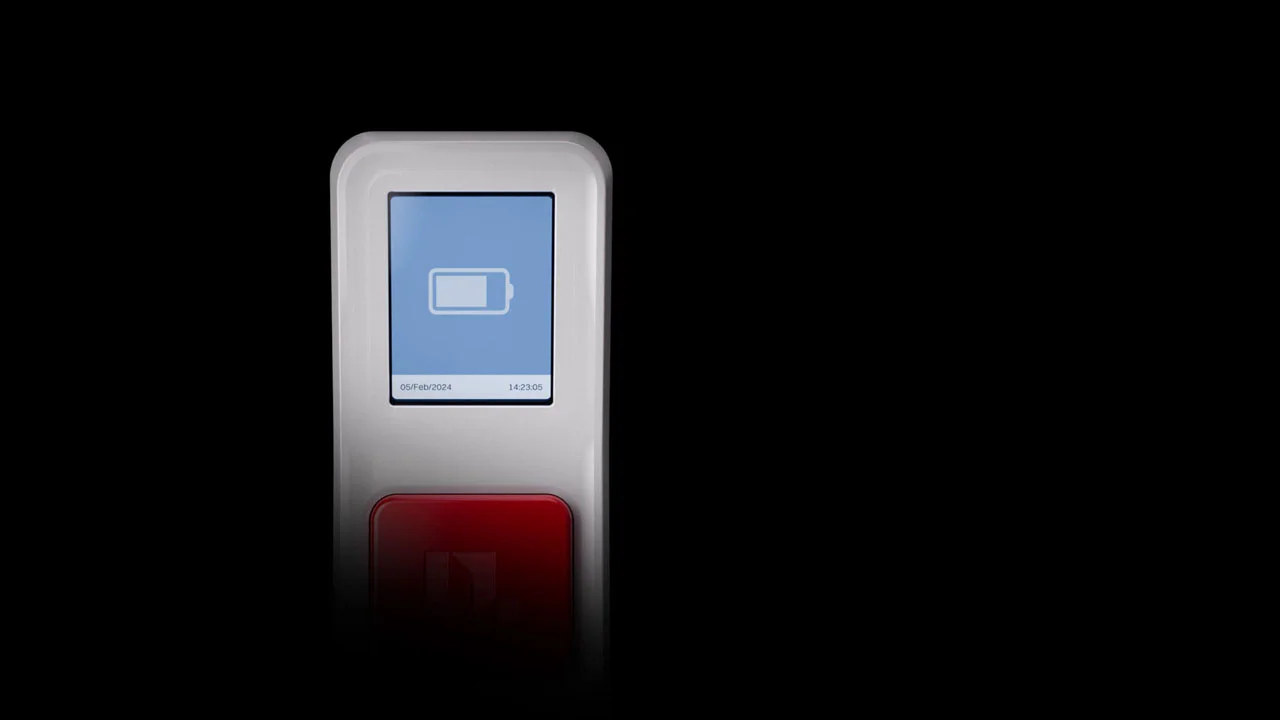

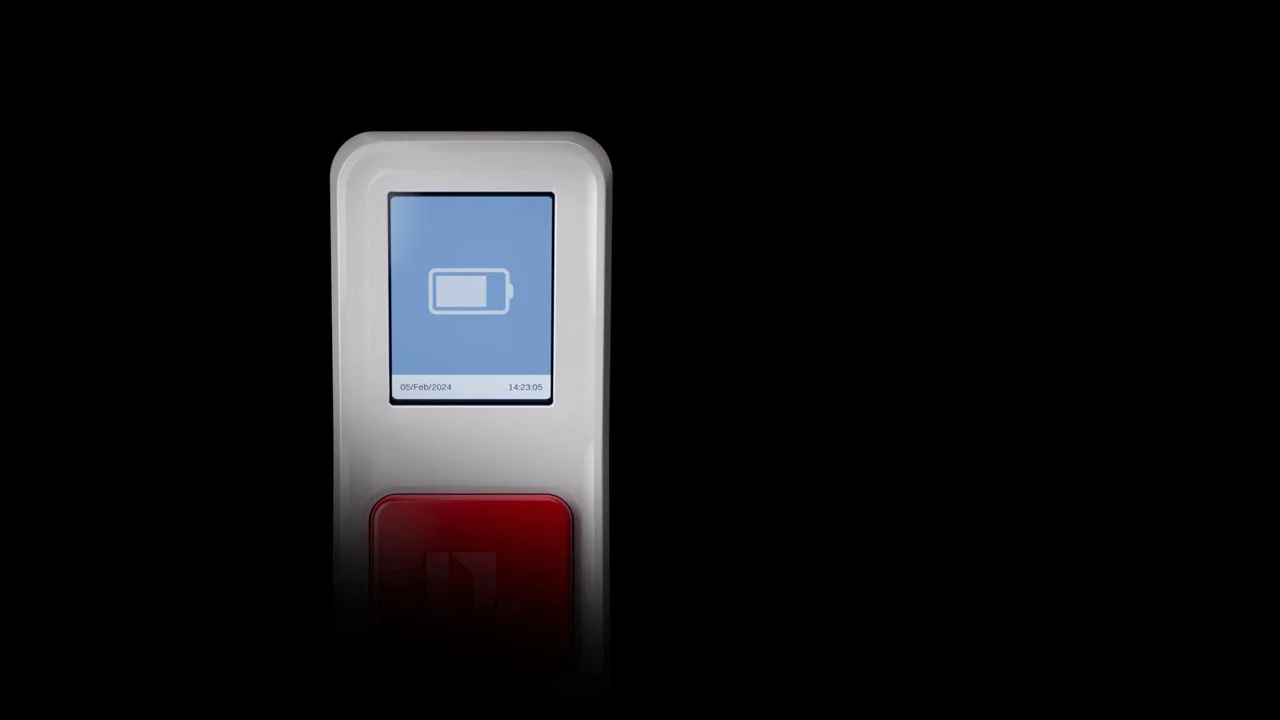

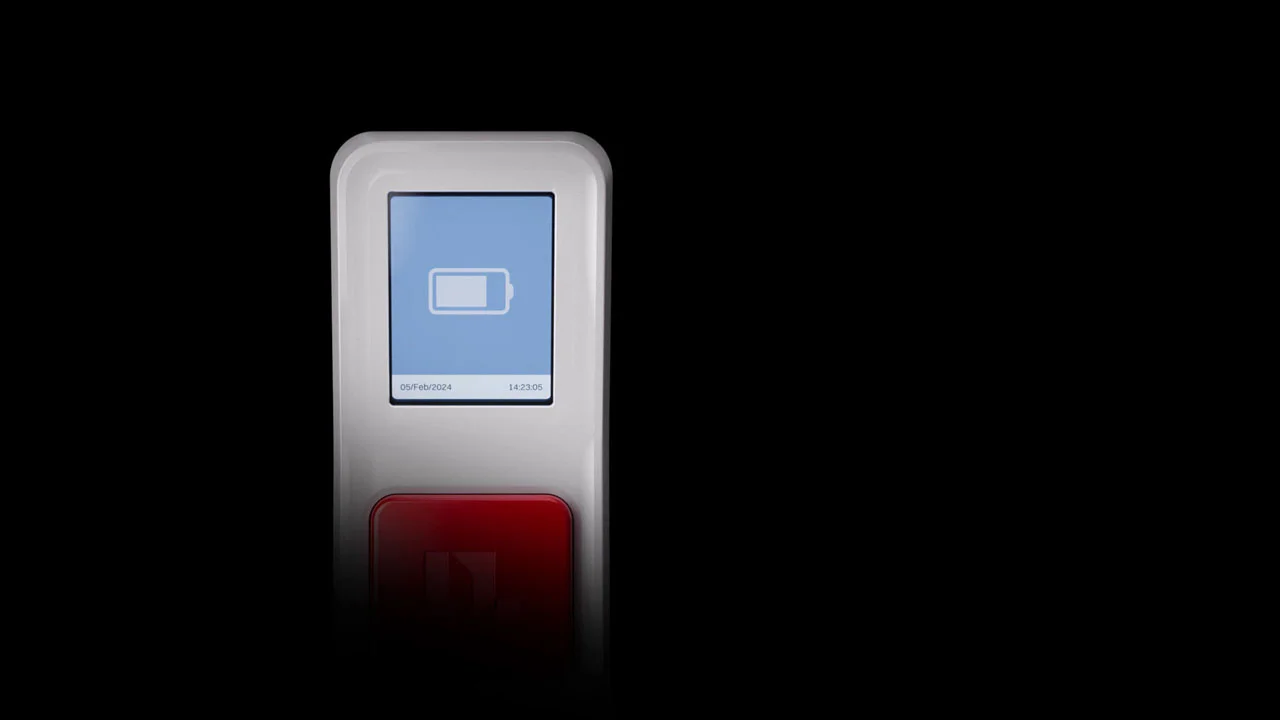

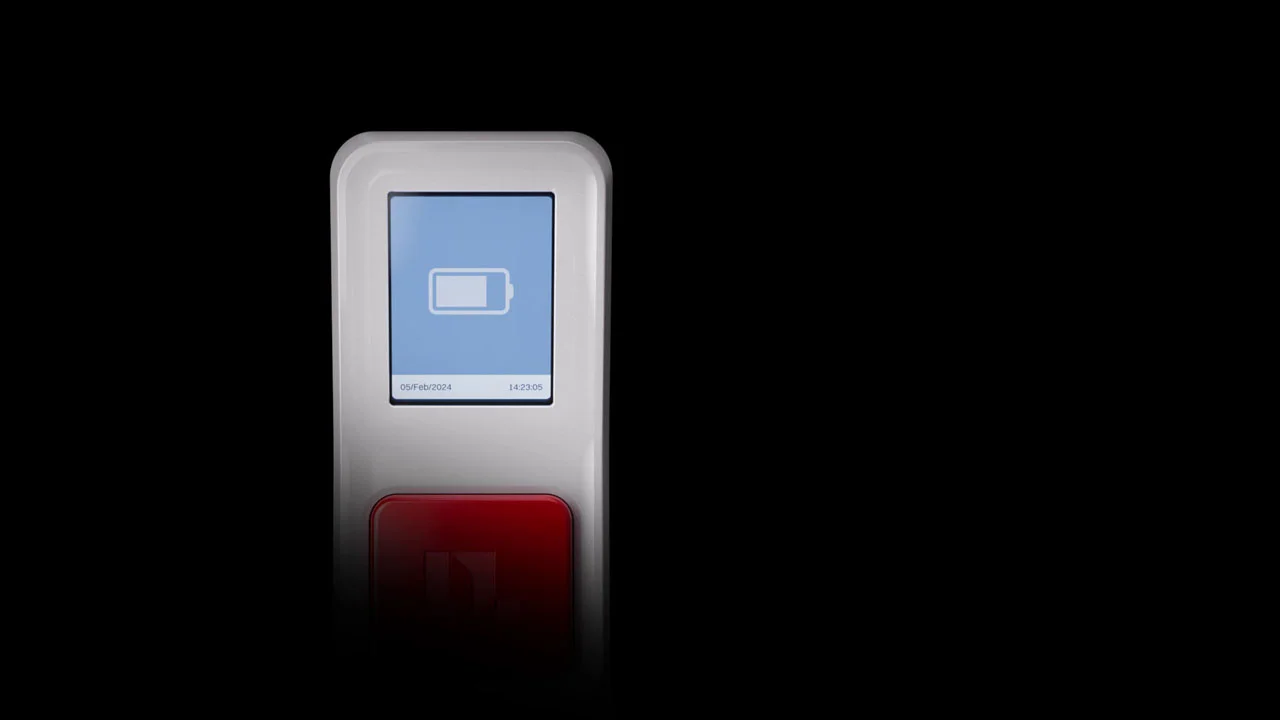

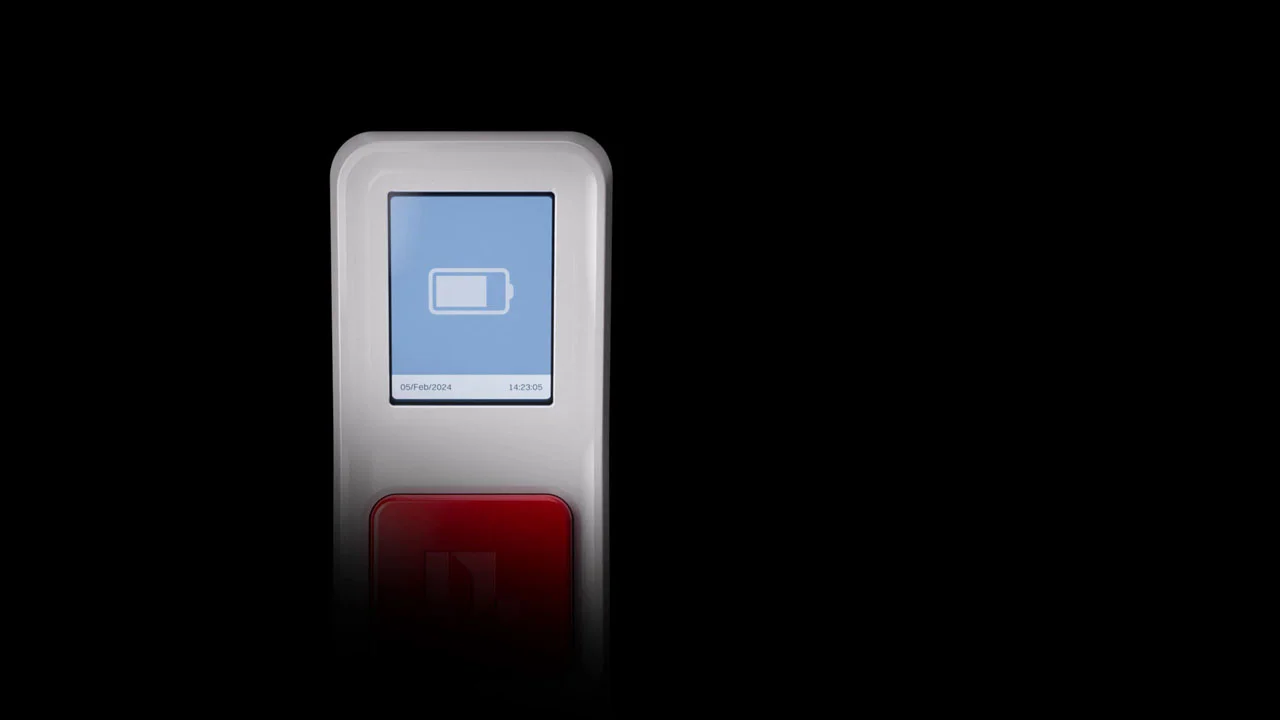

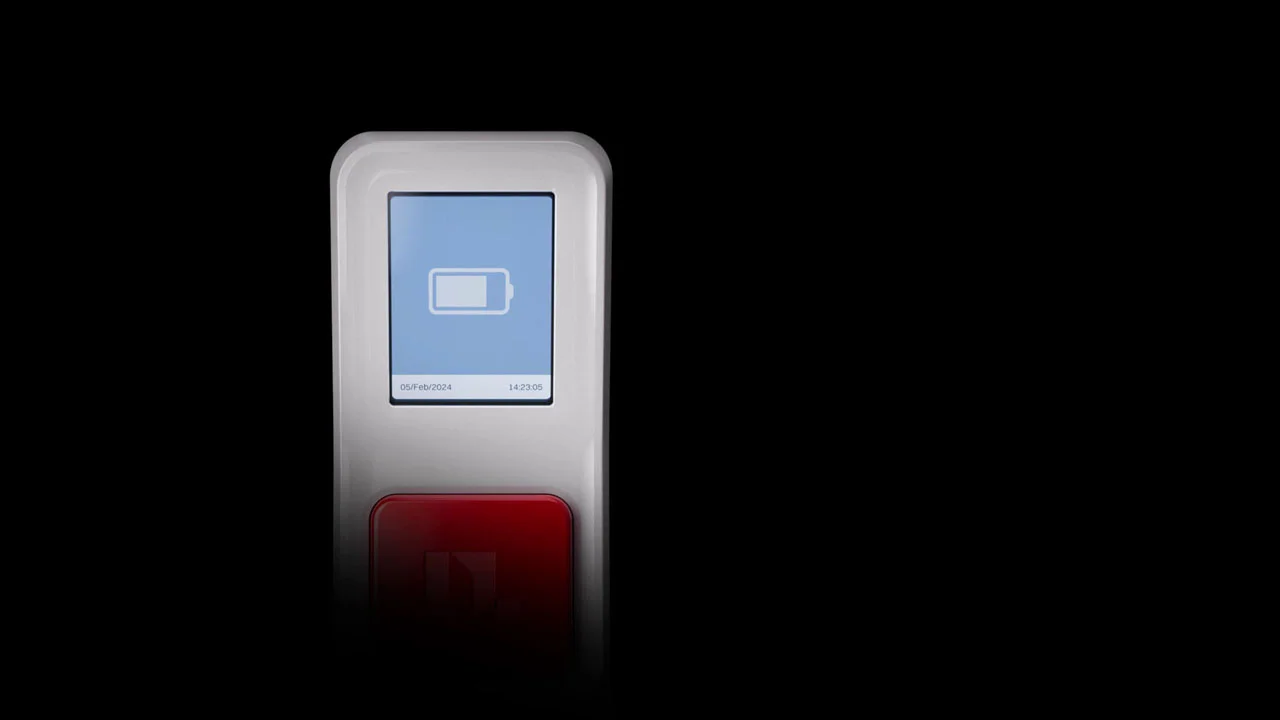

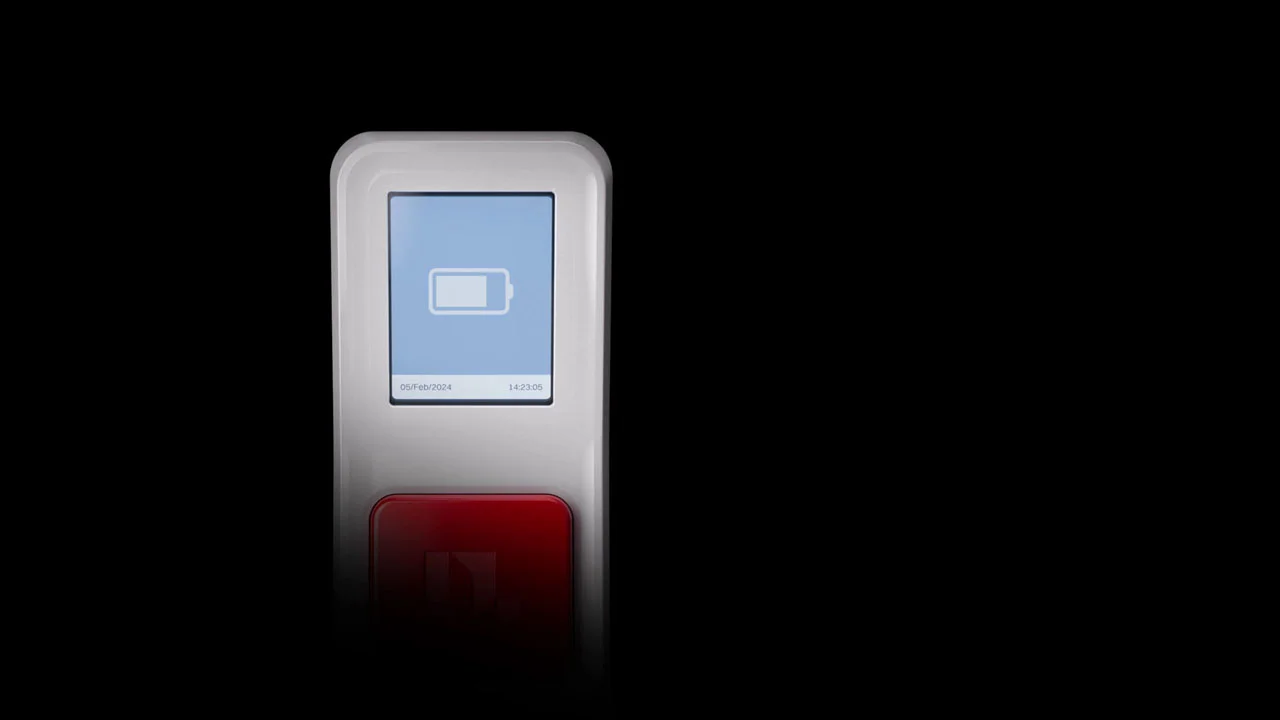

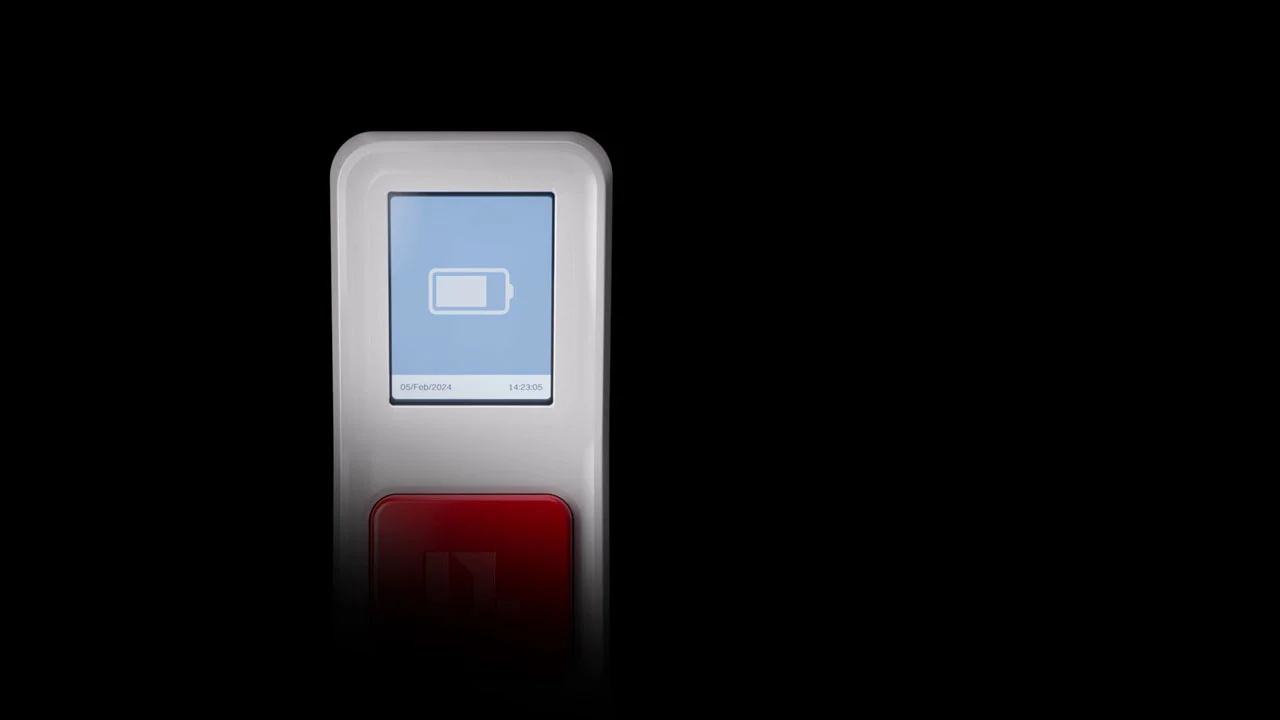

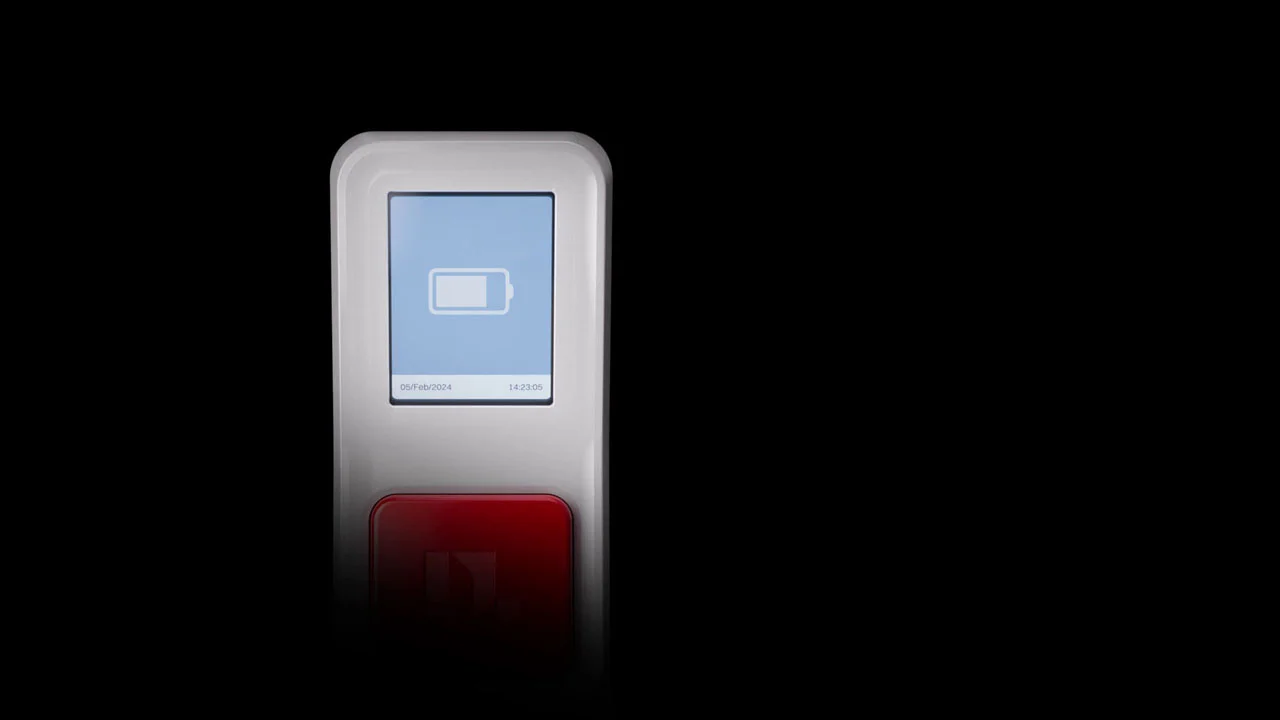

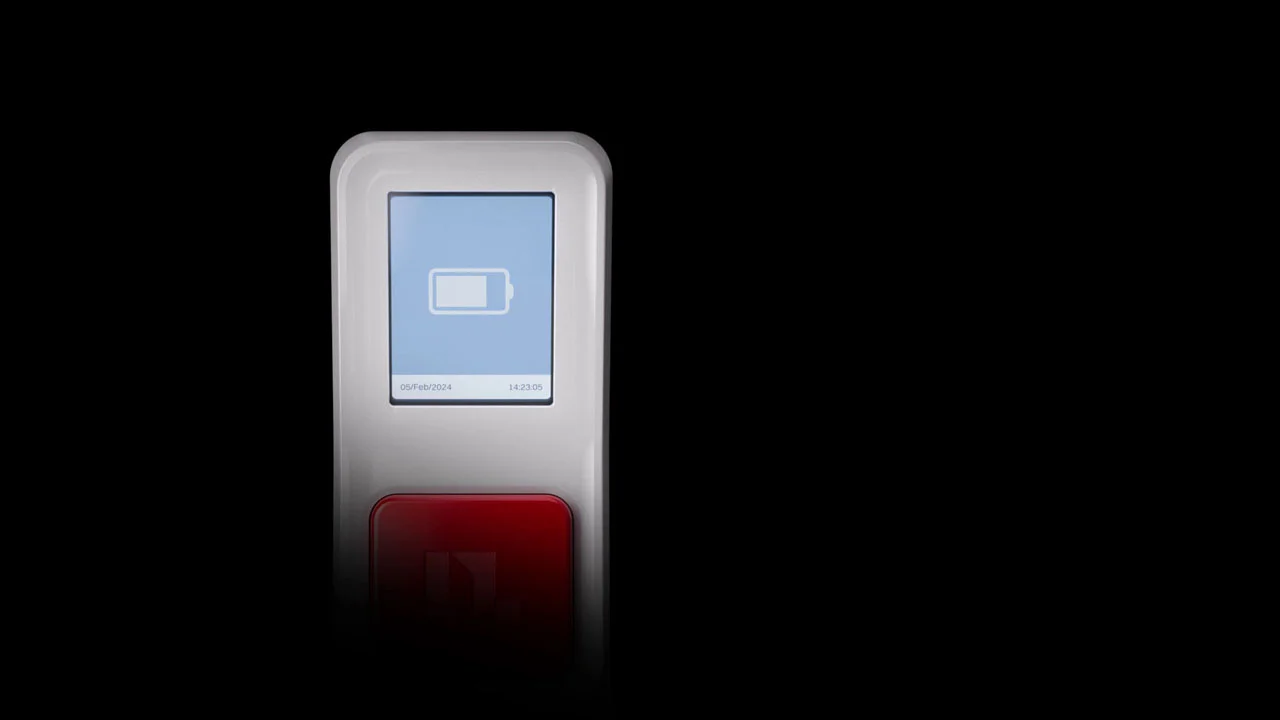

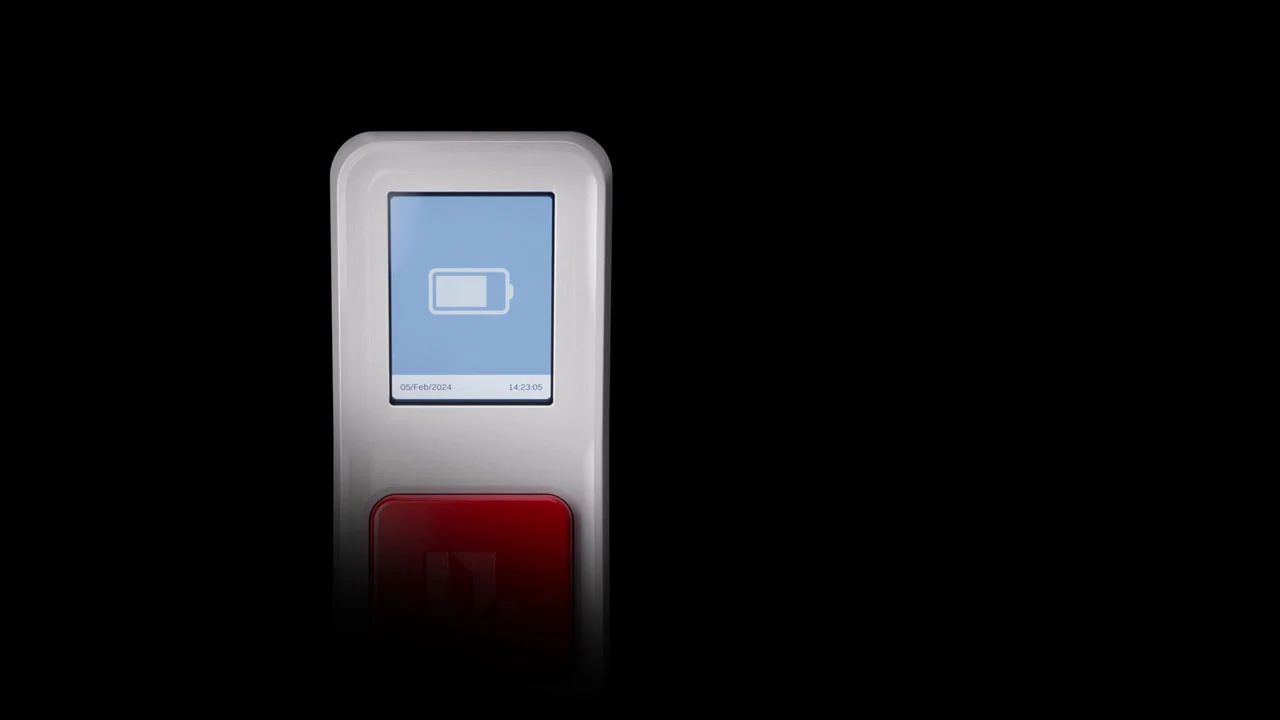

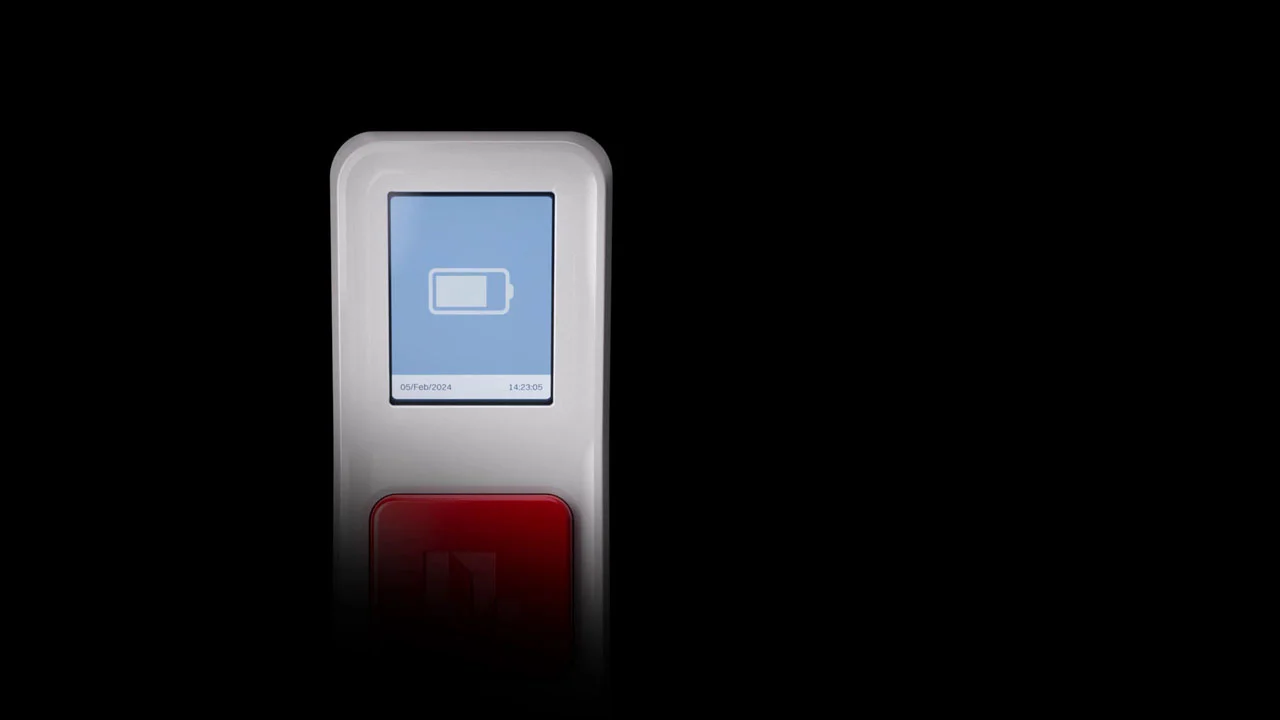

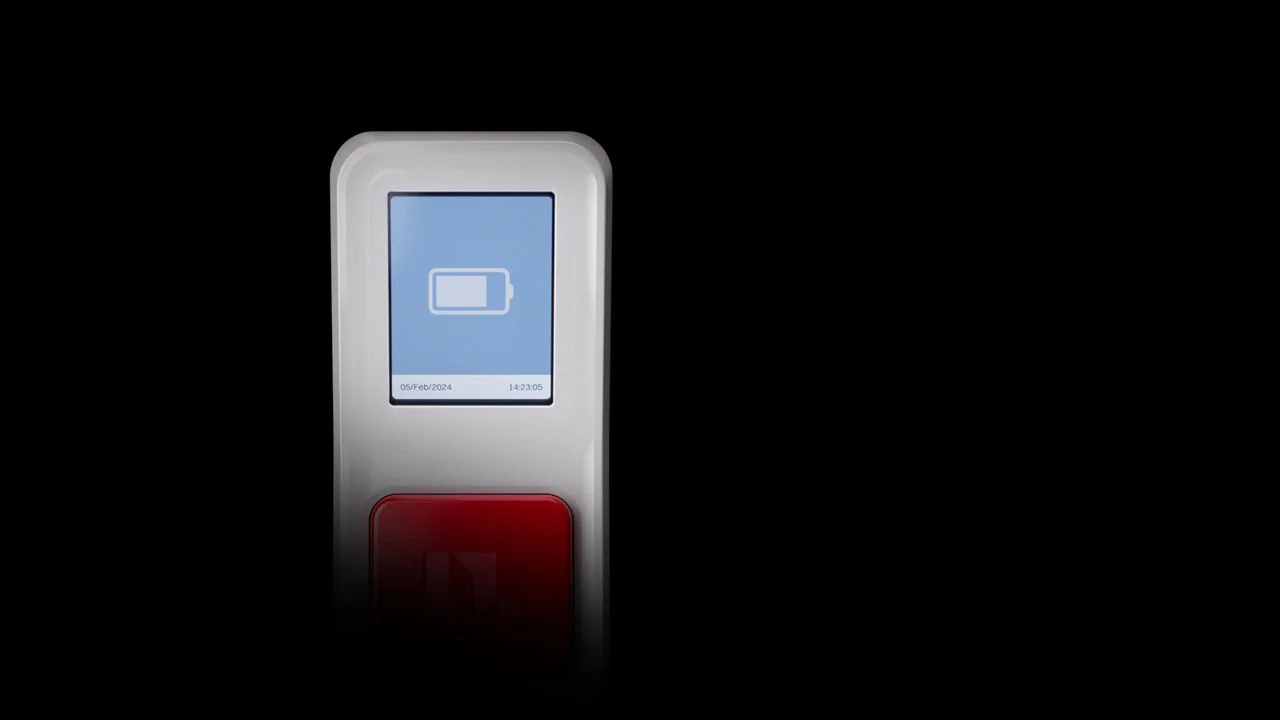

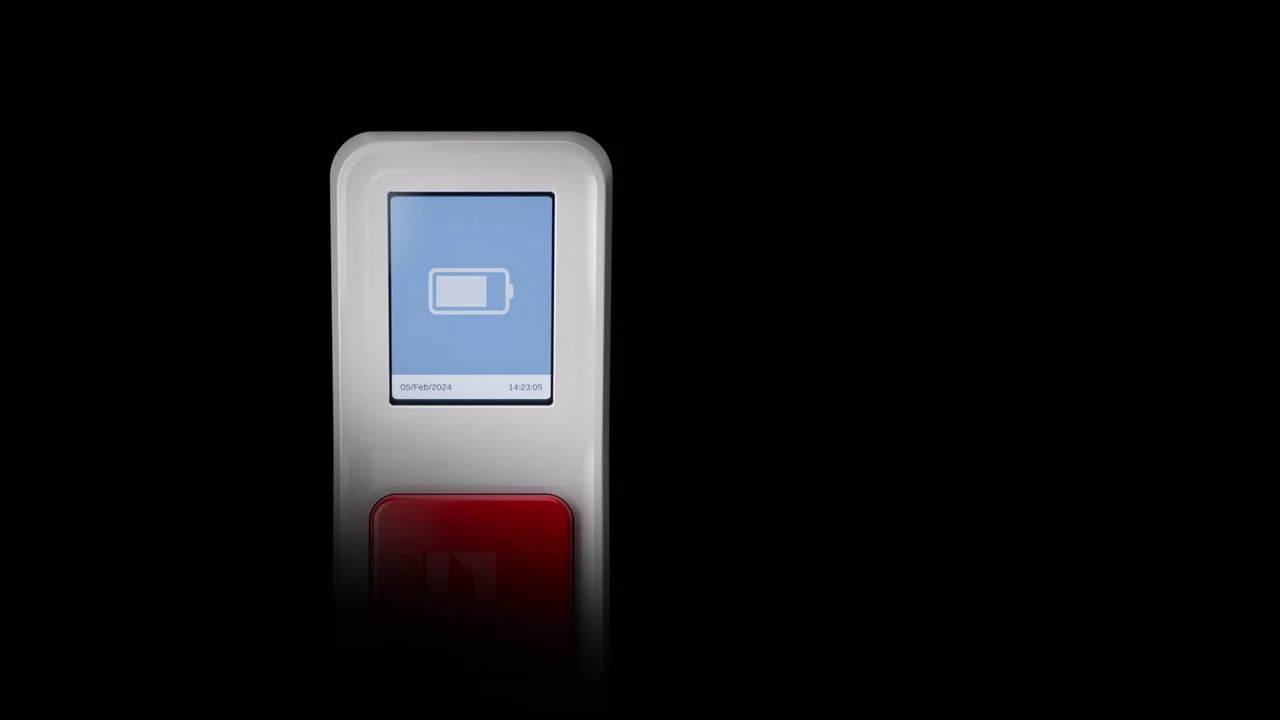

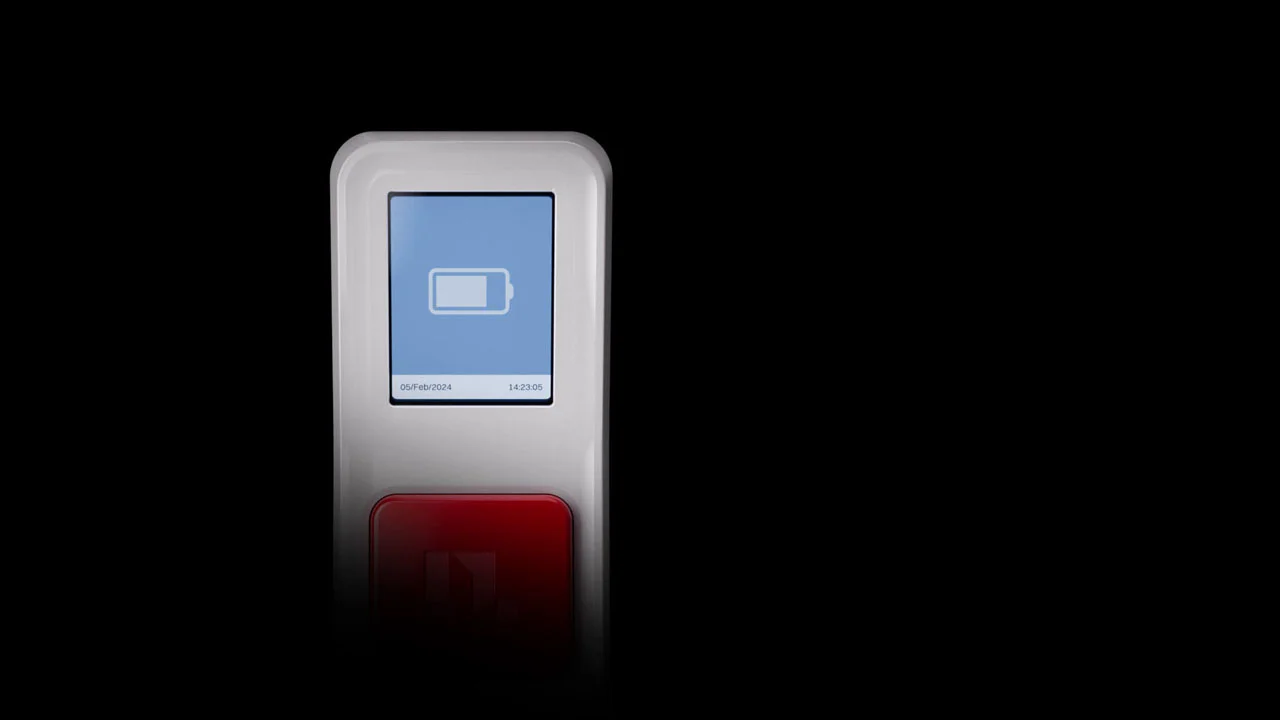

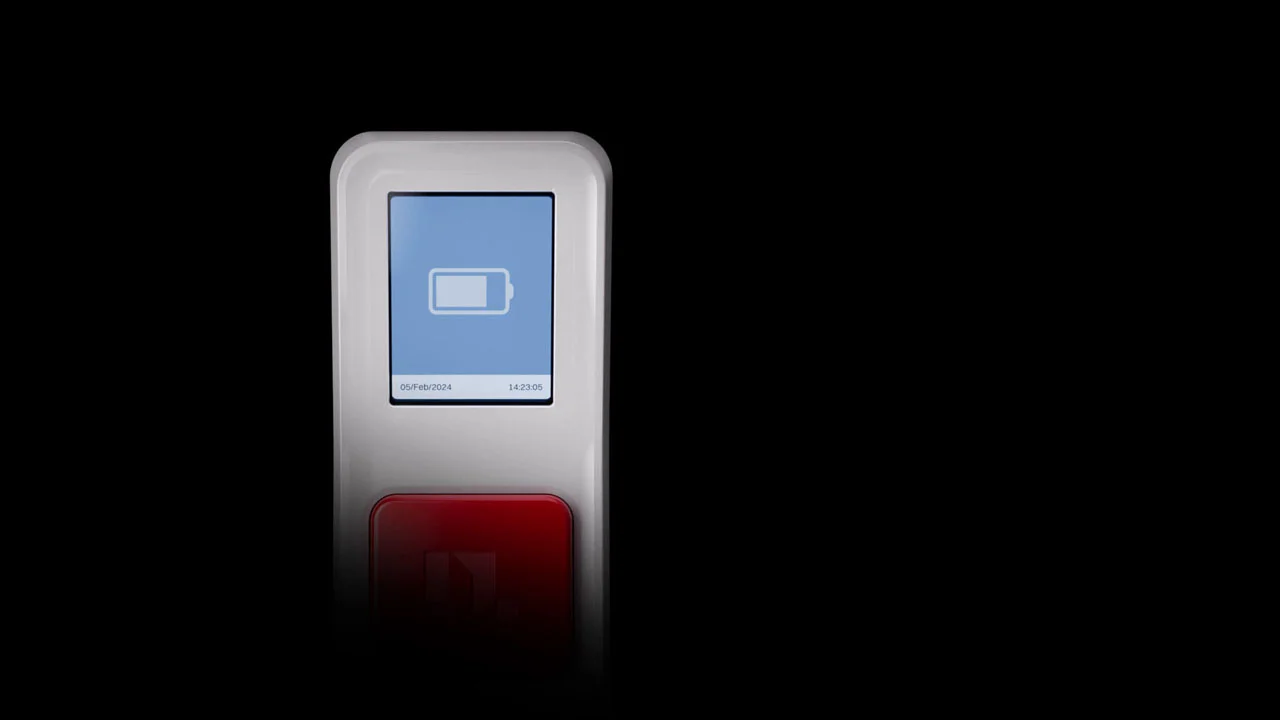

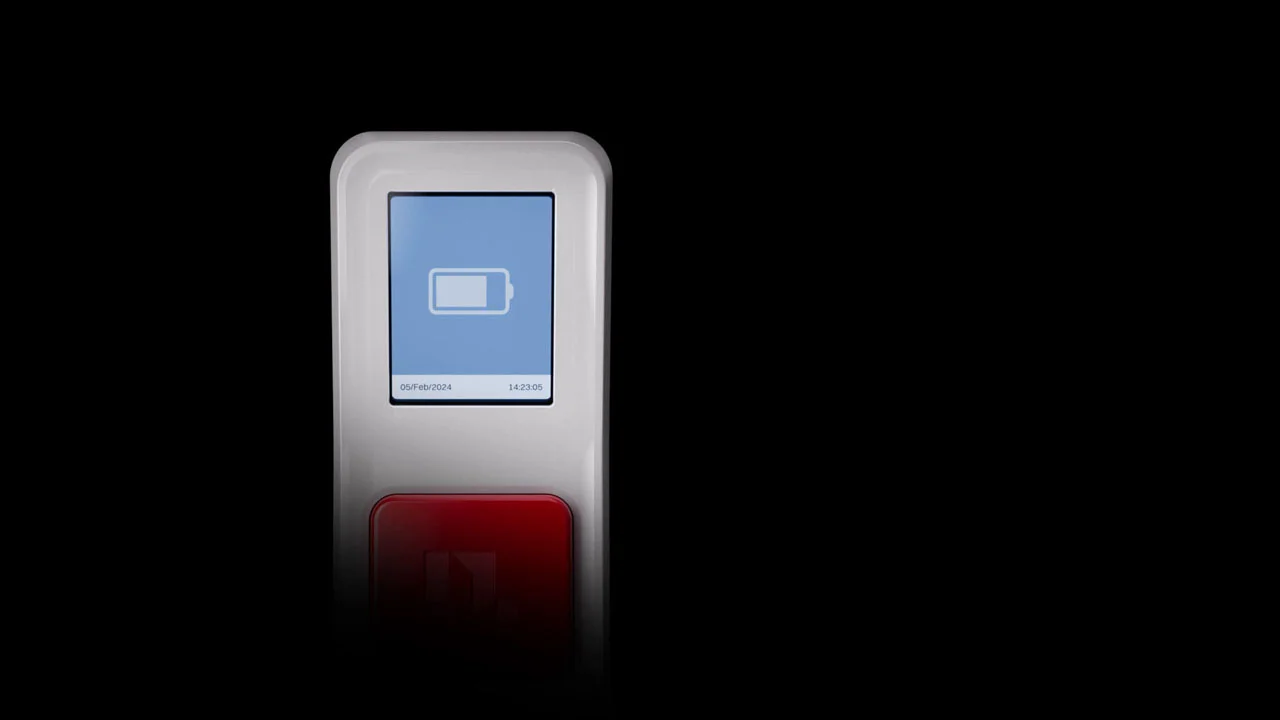

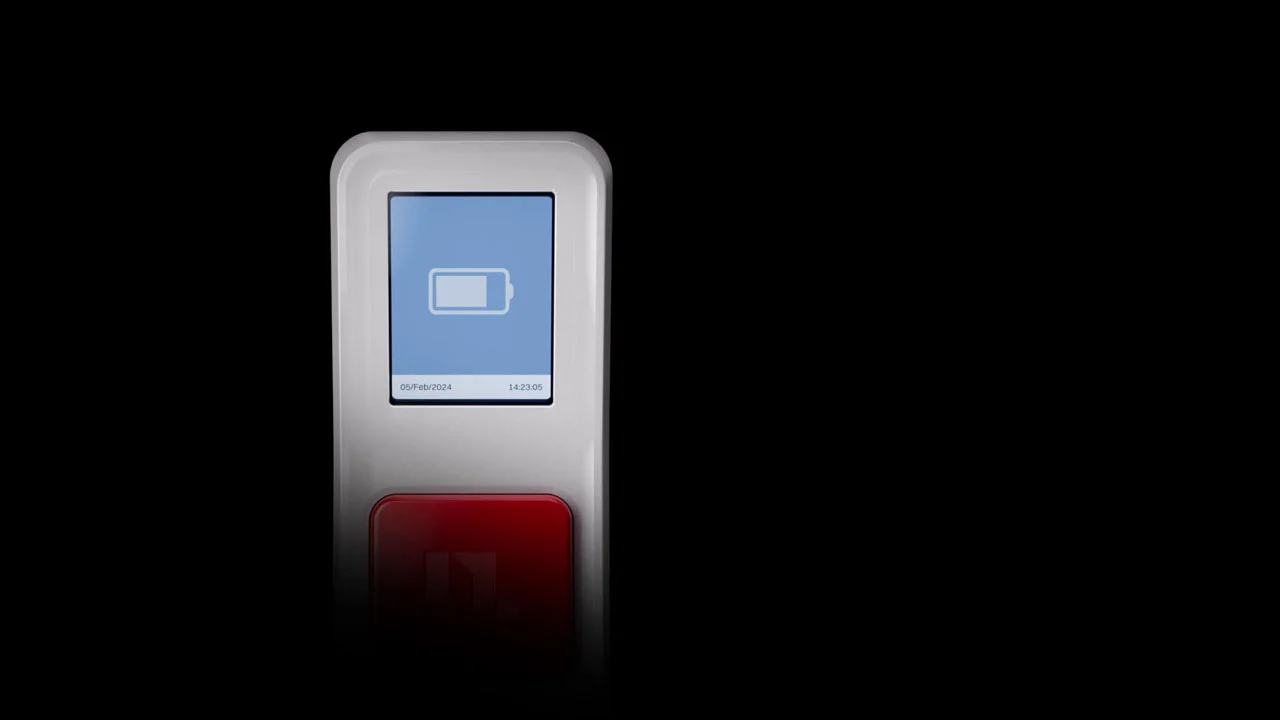

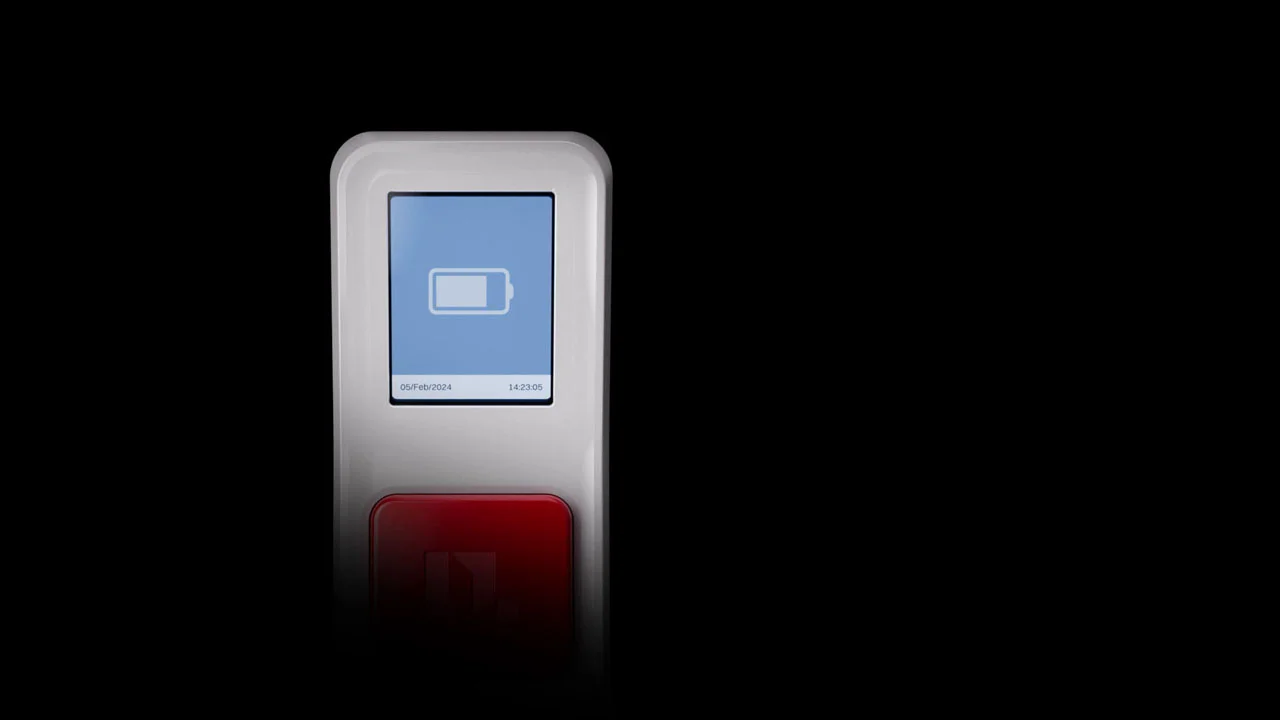

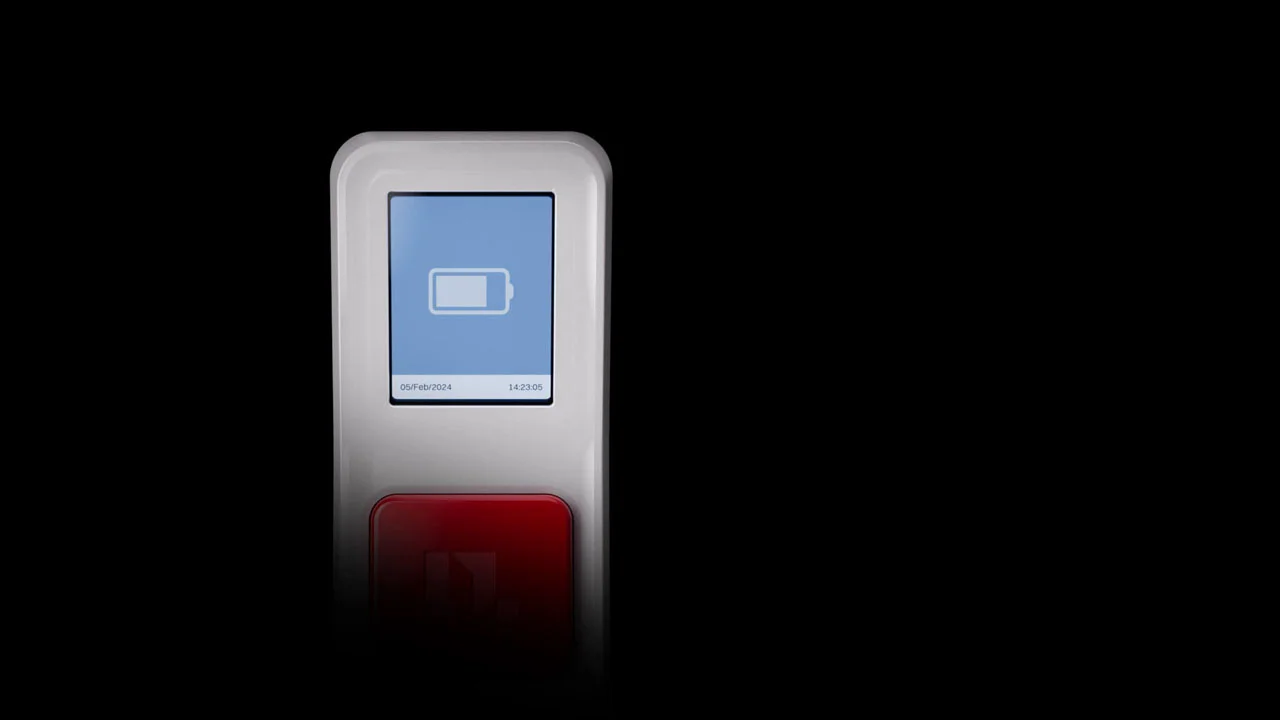

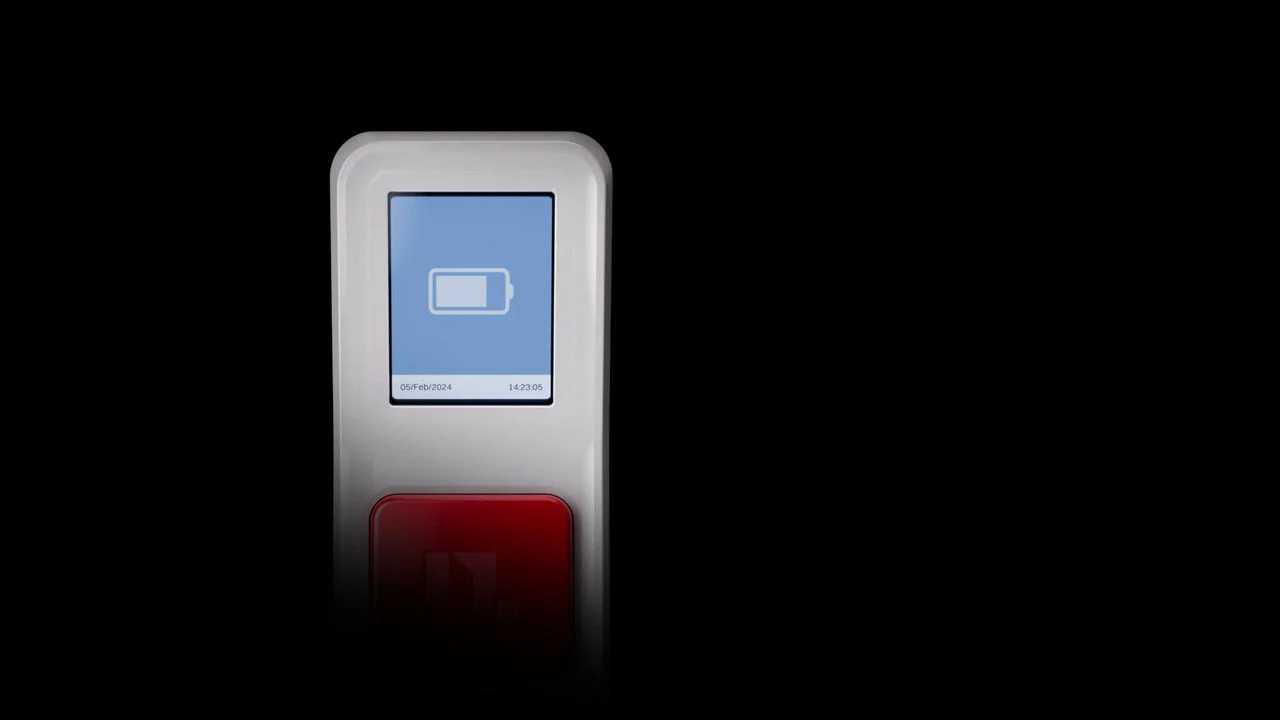

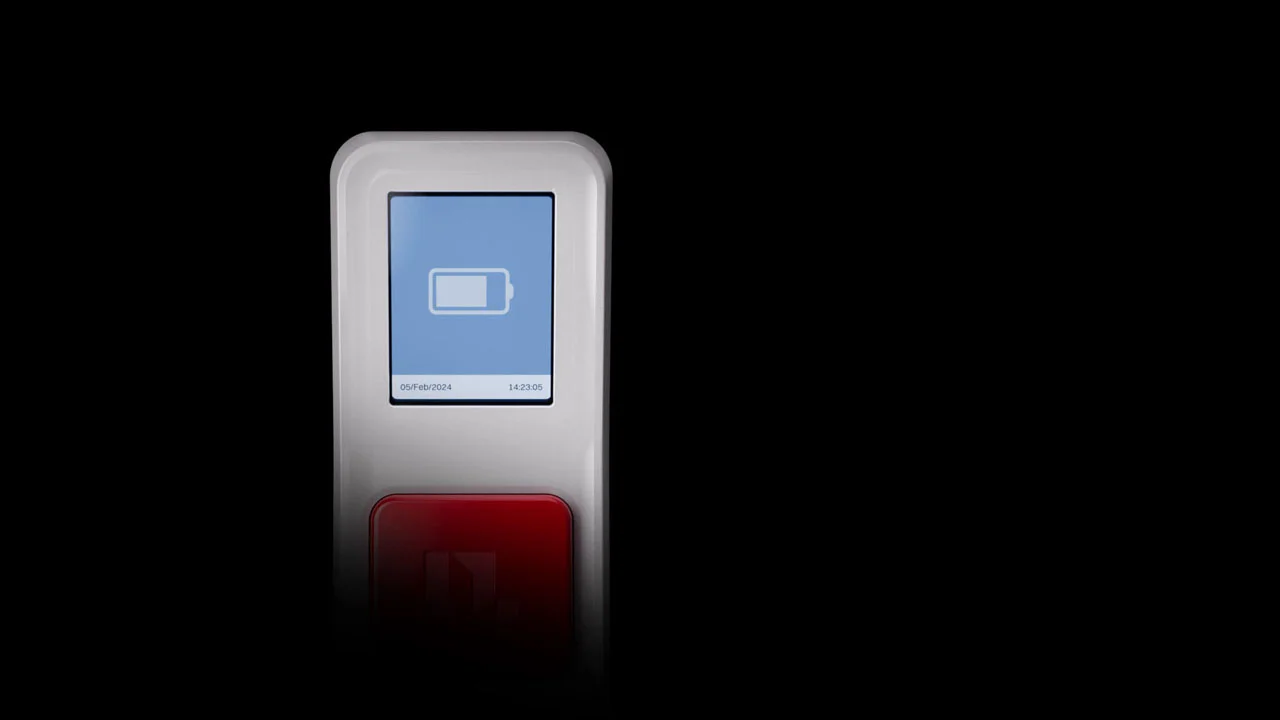

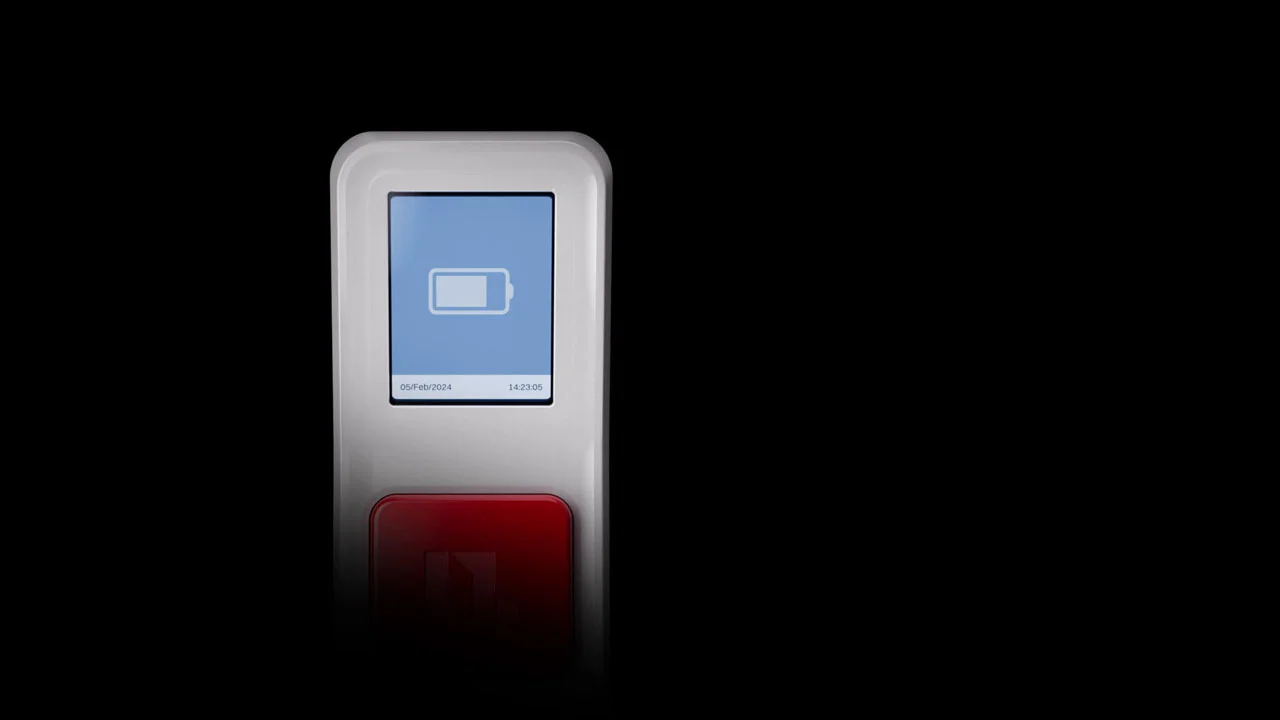

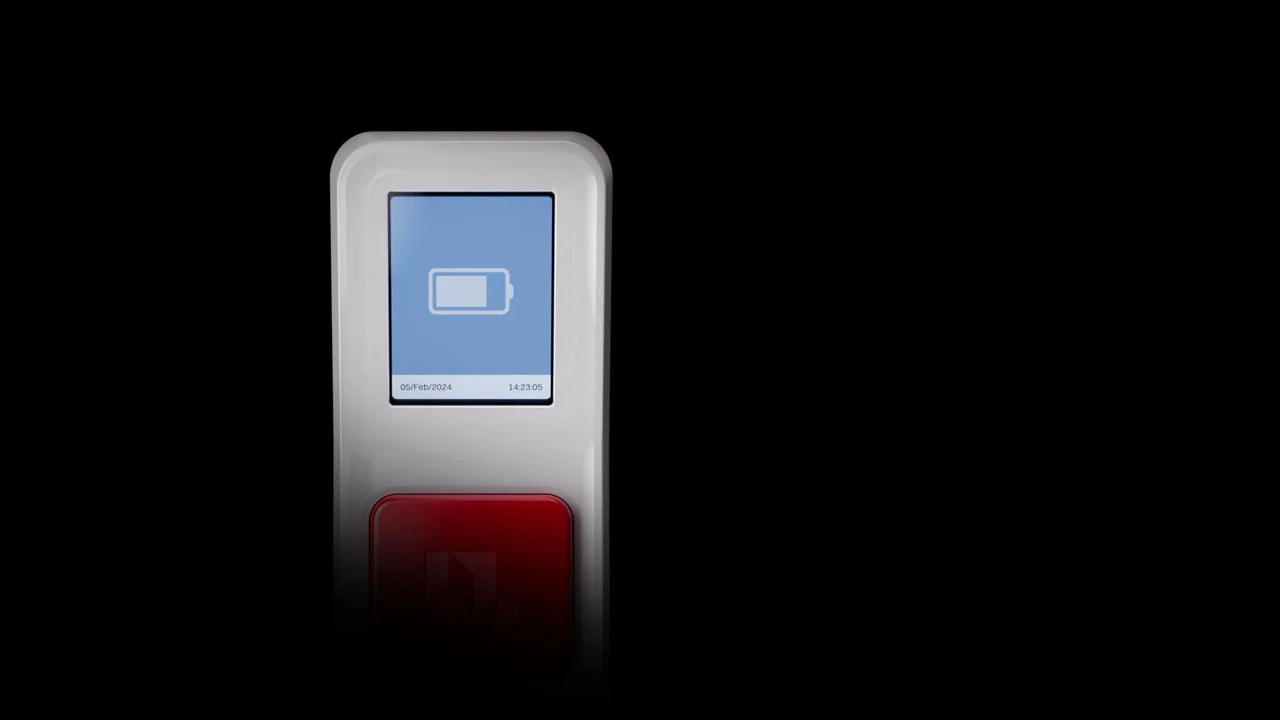

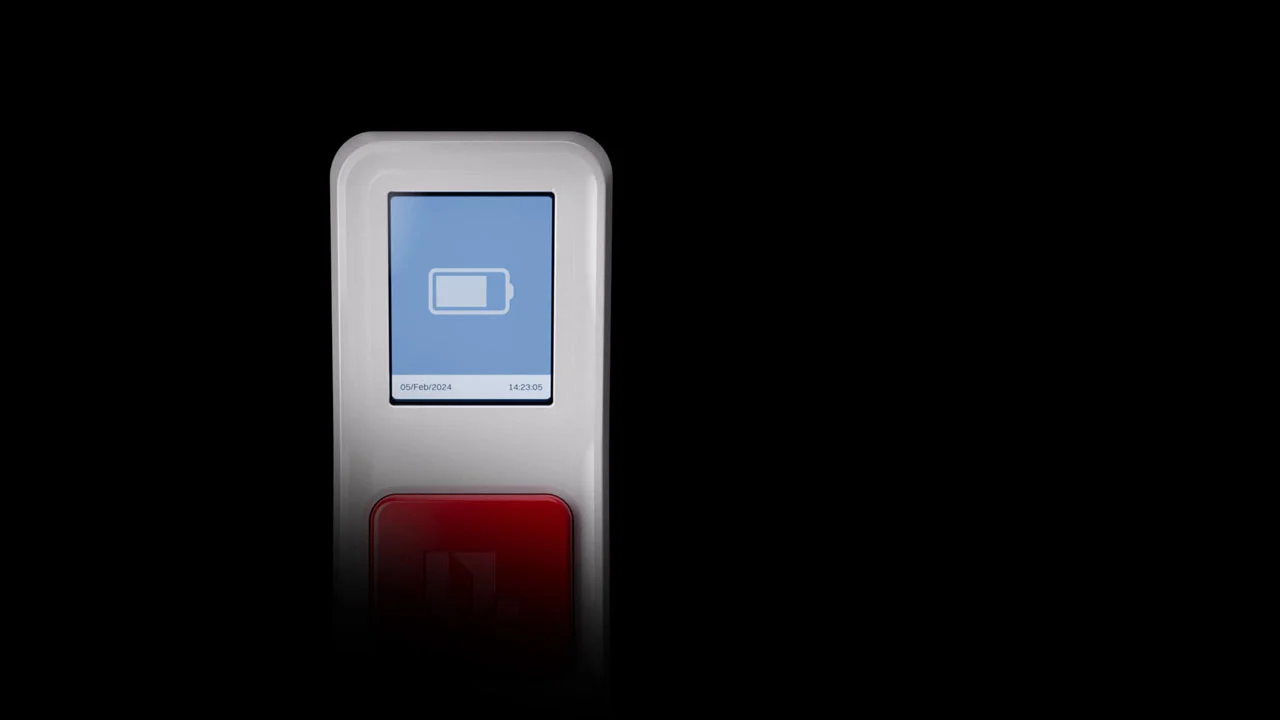

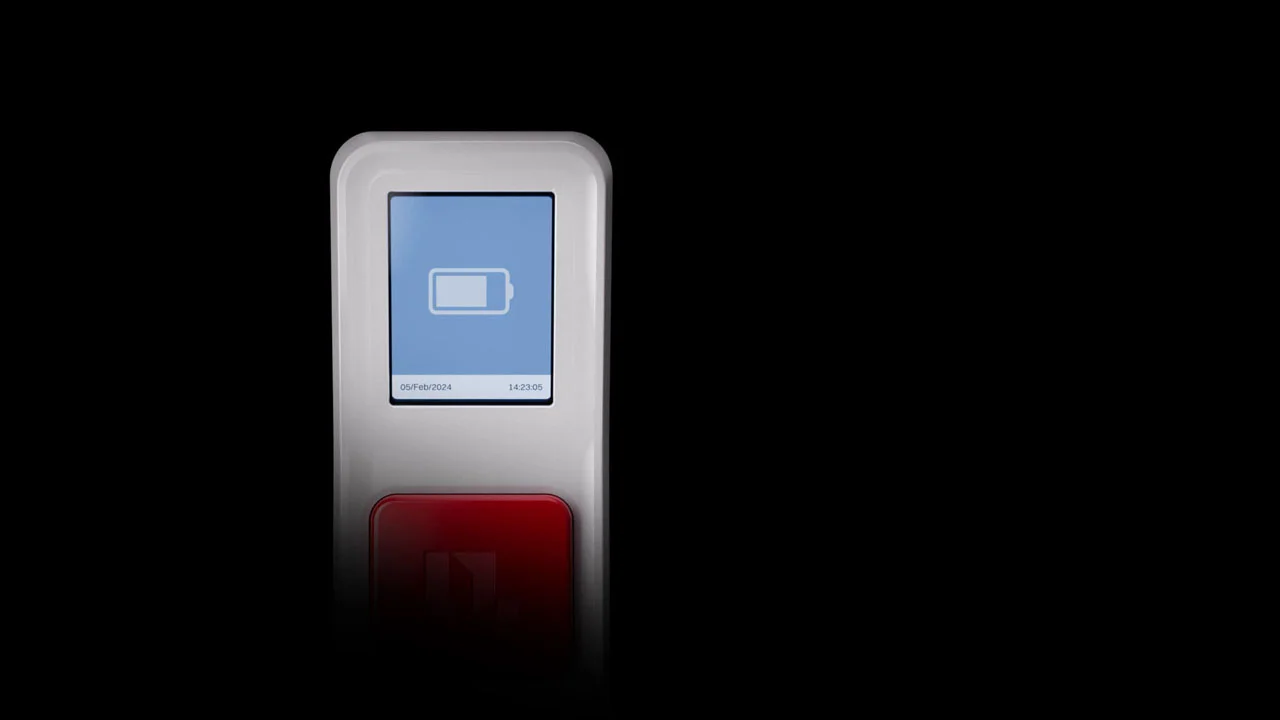

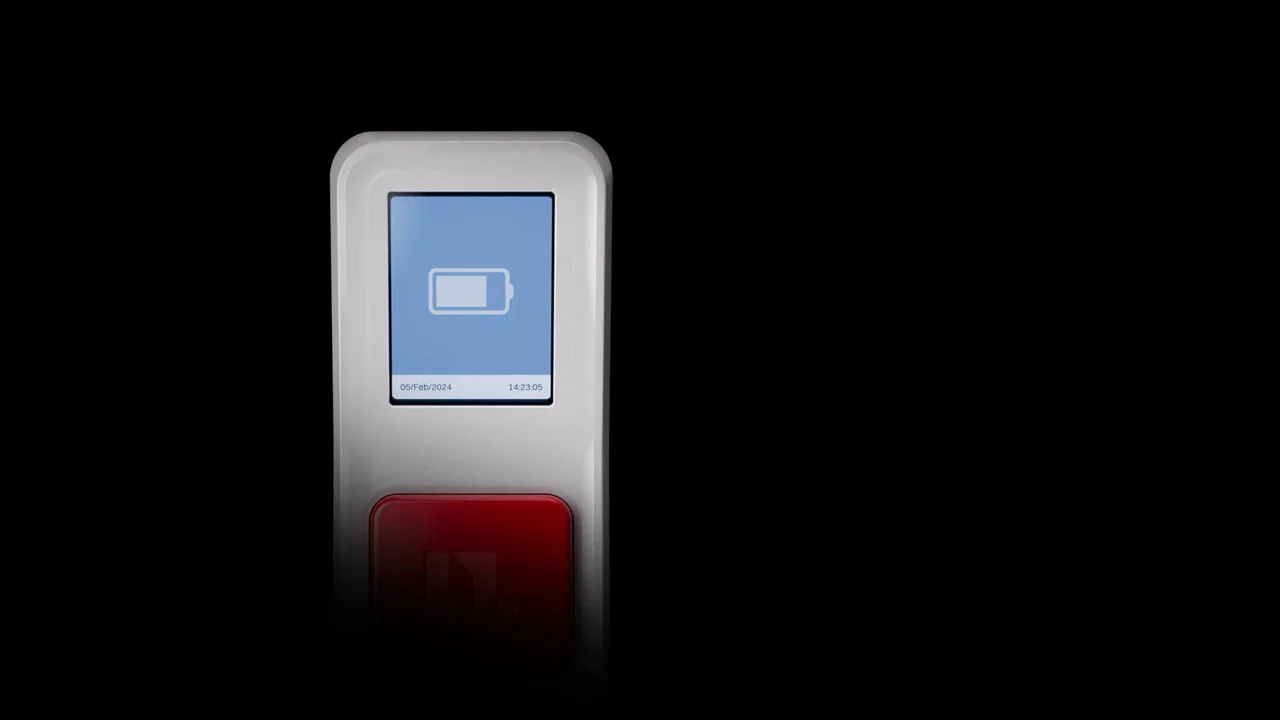

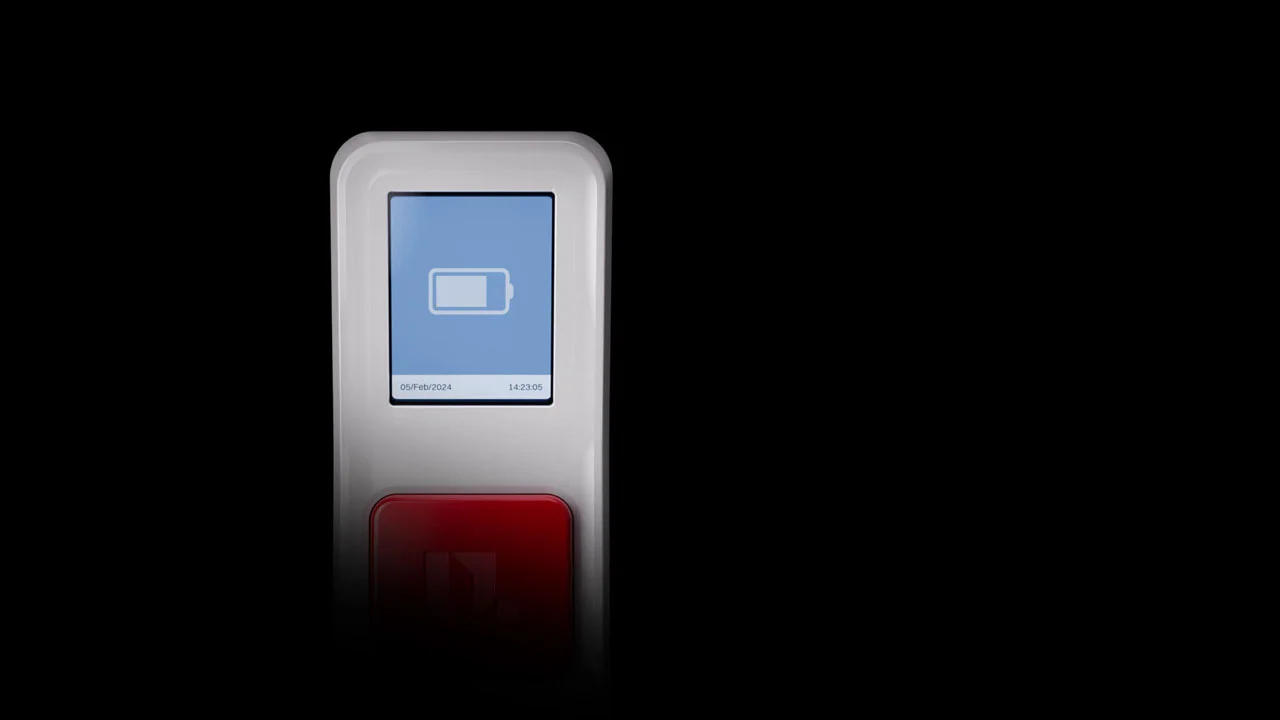

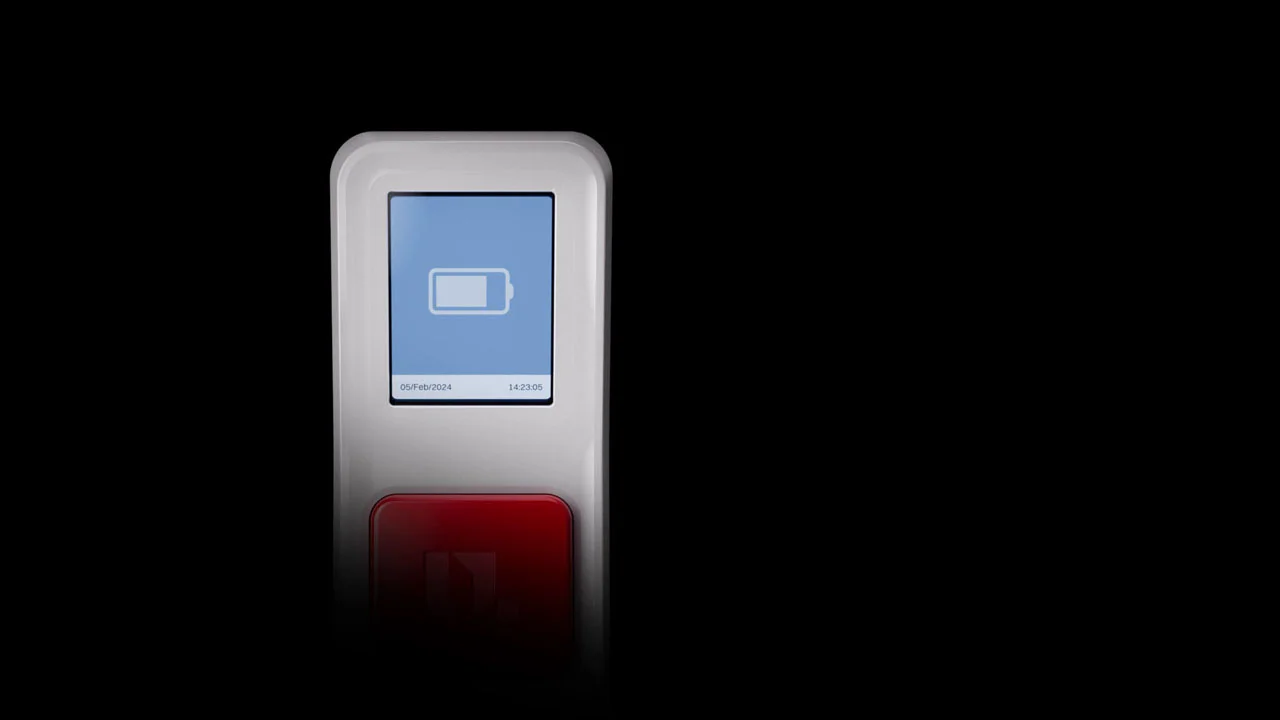

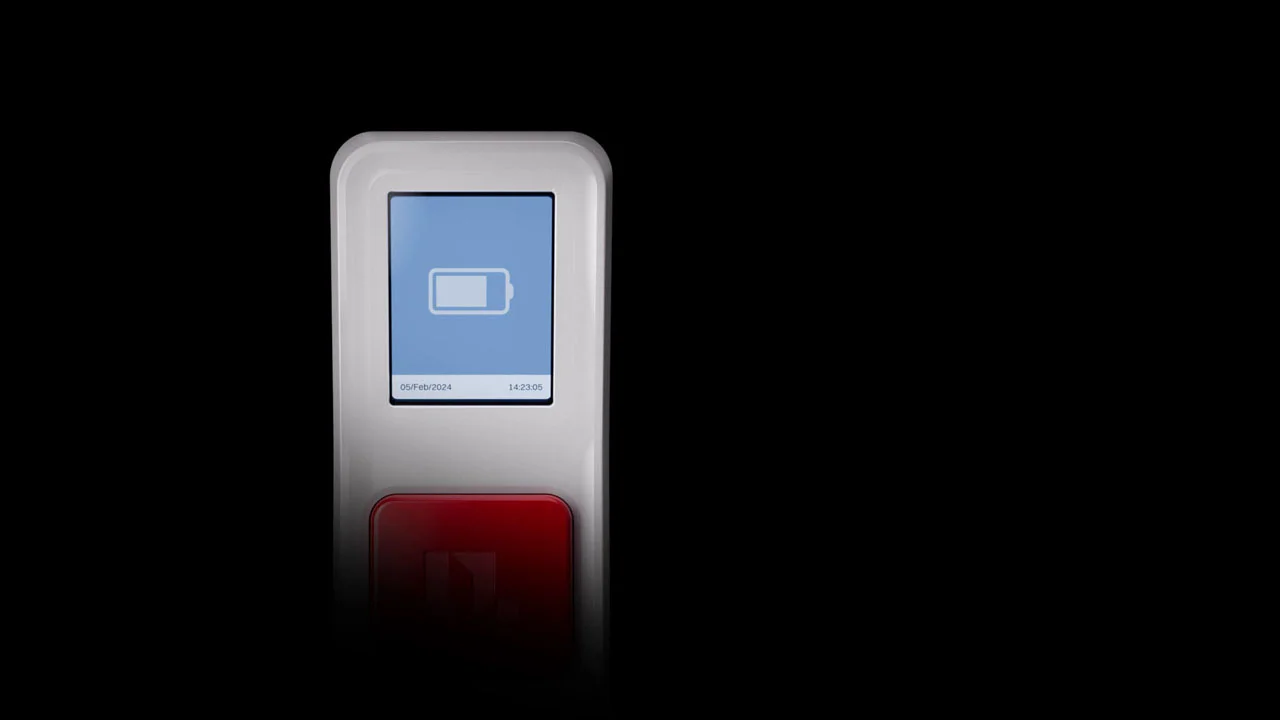

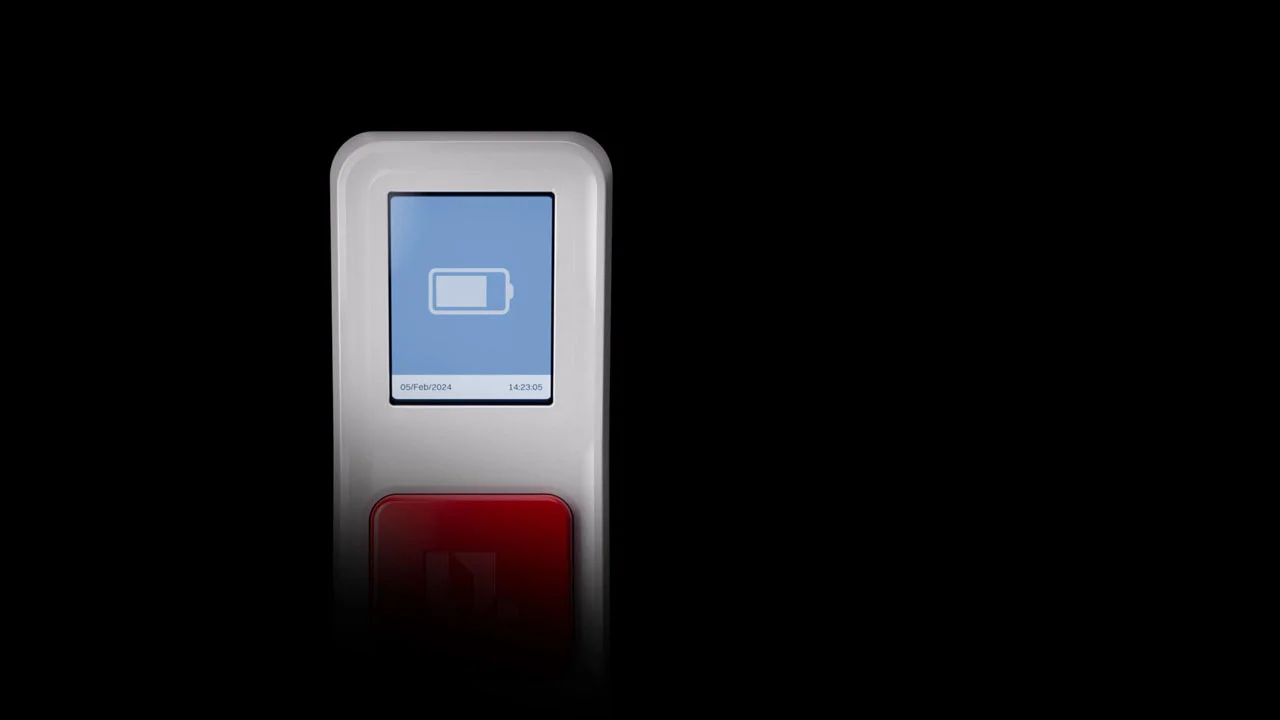

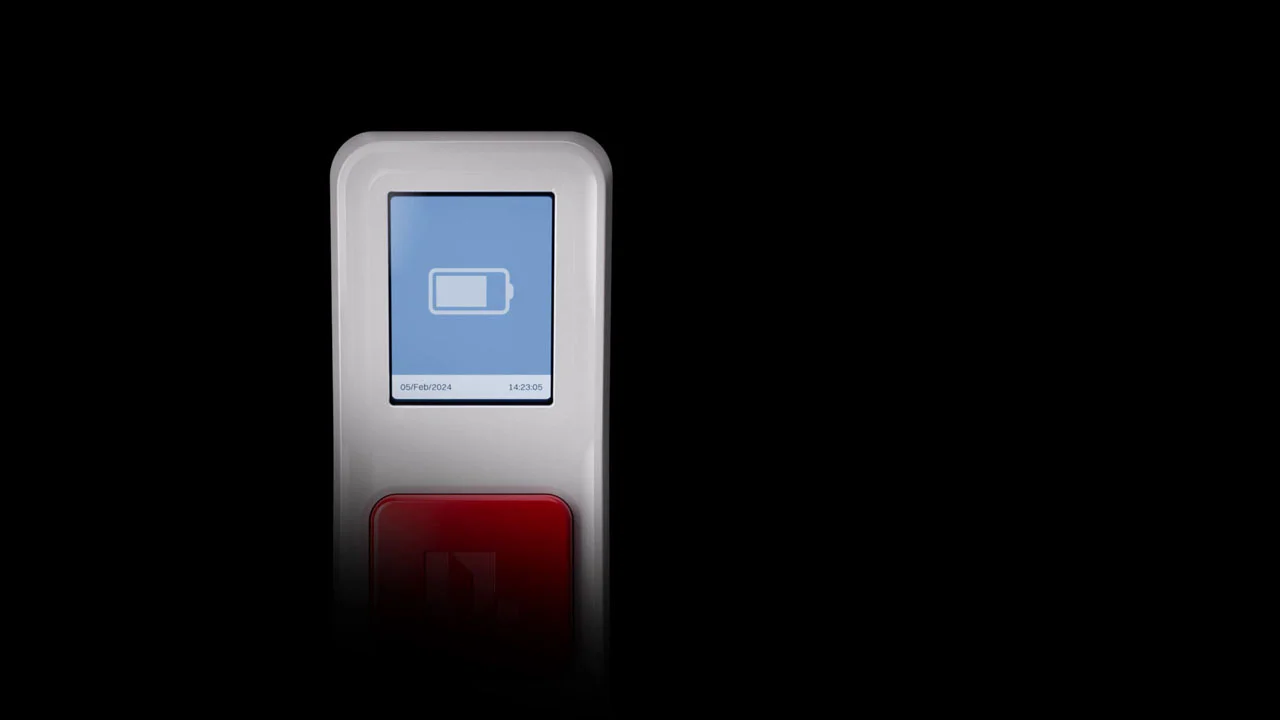

Pressing the red button in every time it's compeleted will update the production quantity and average SMV in real time.

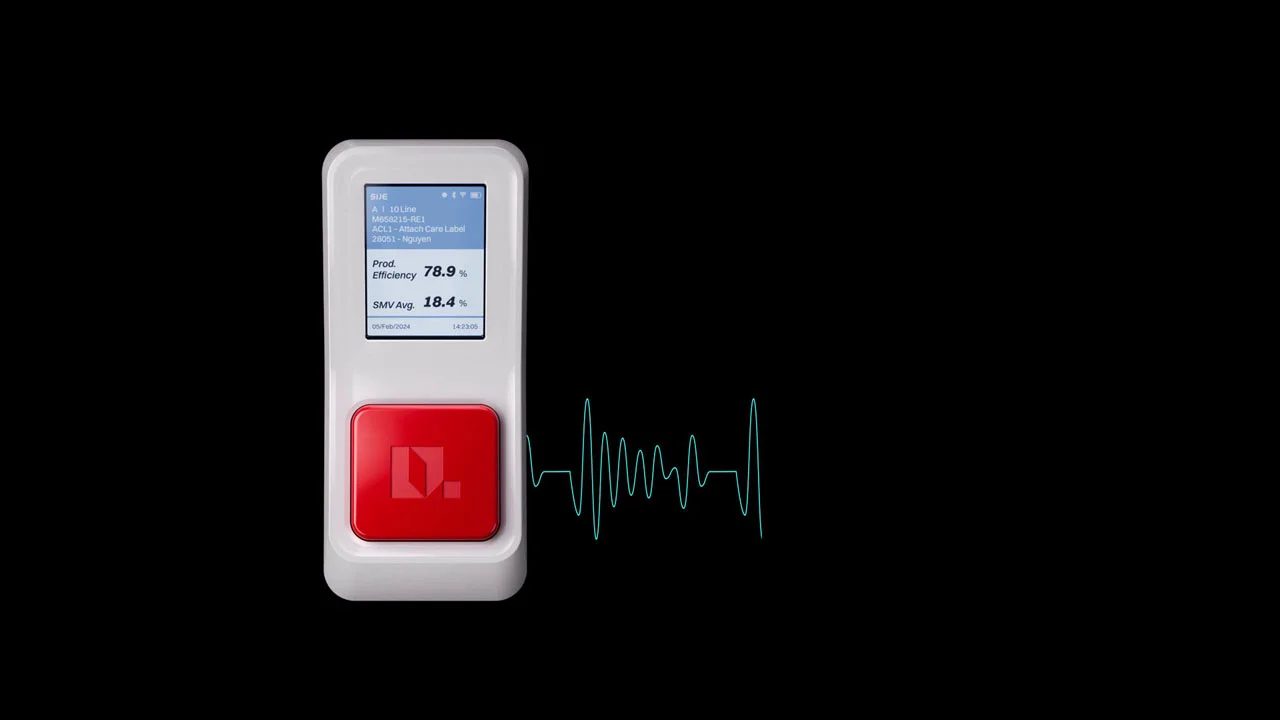

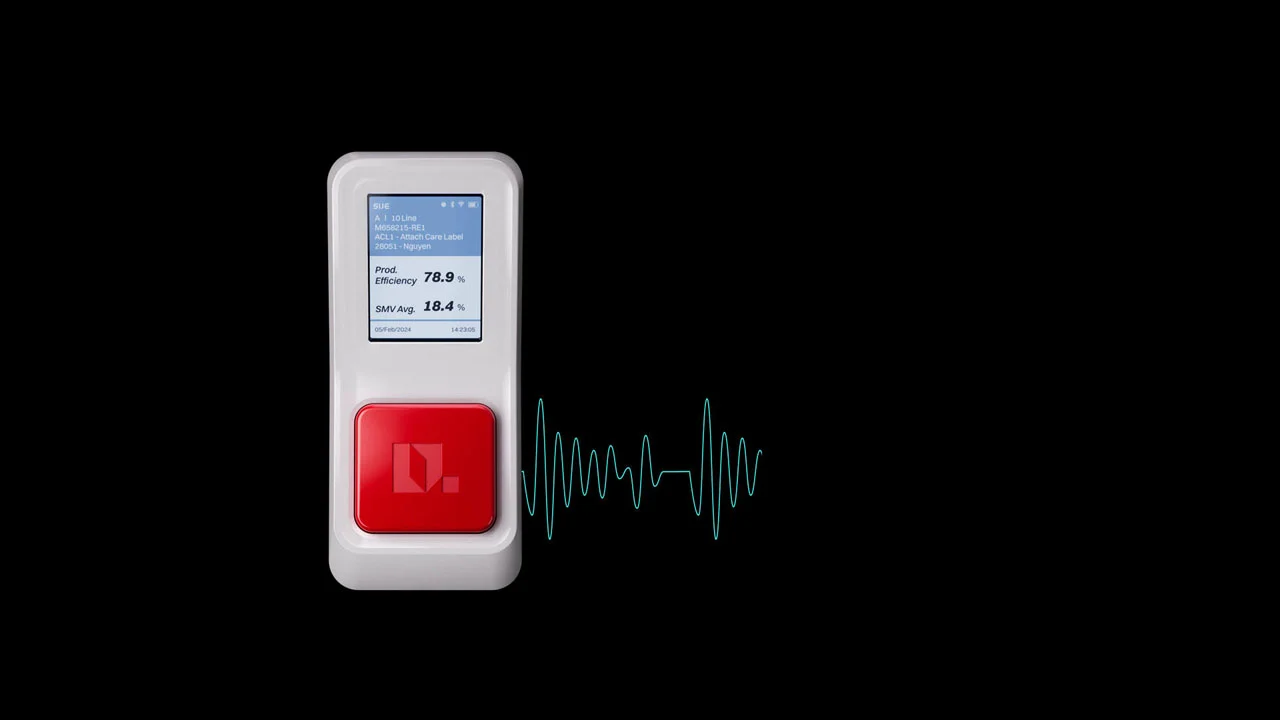

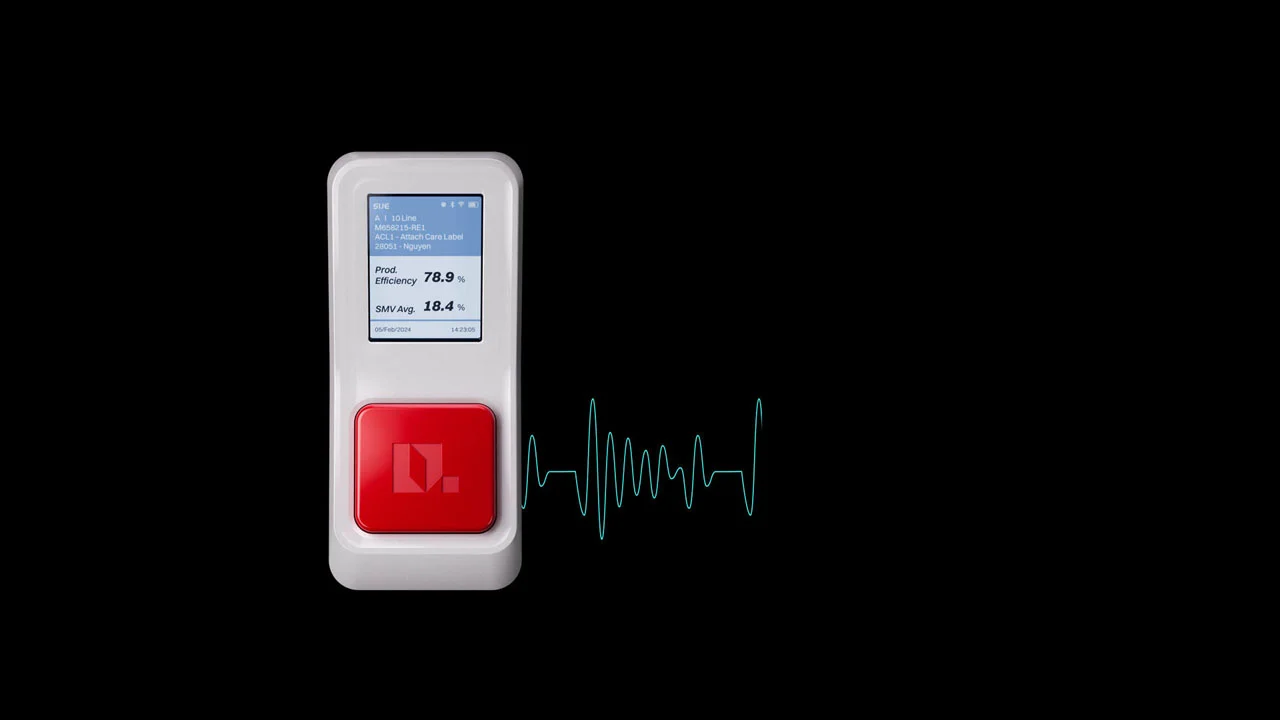

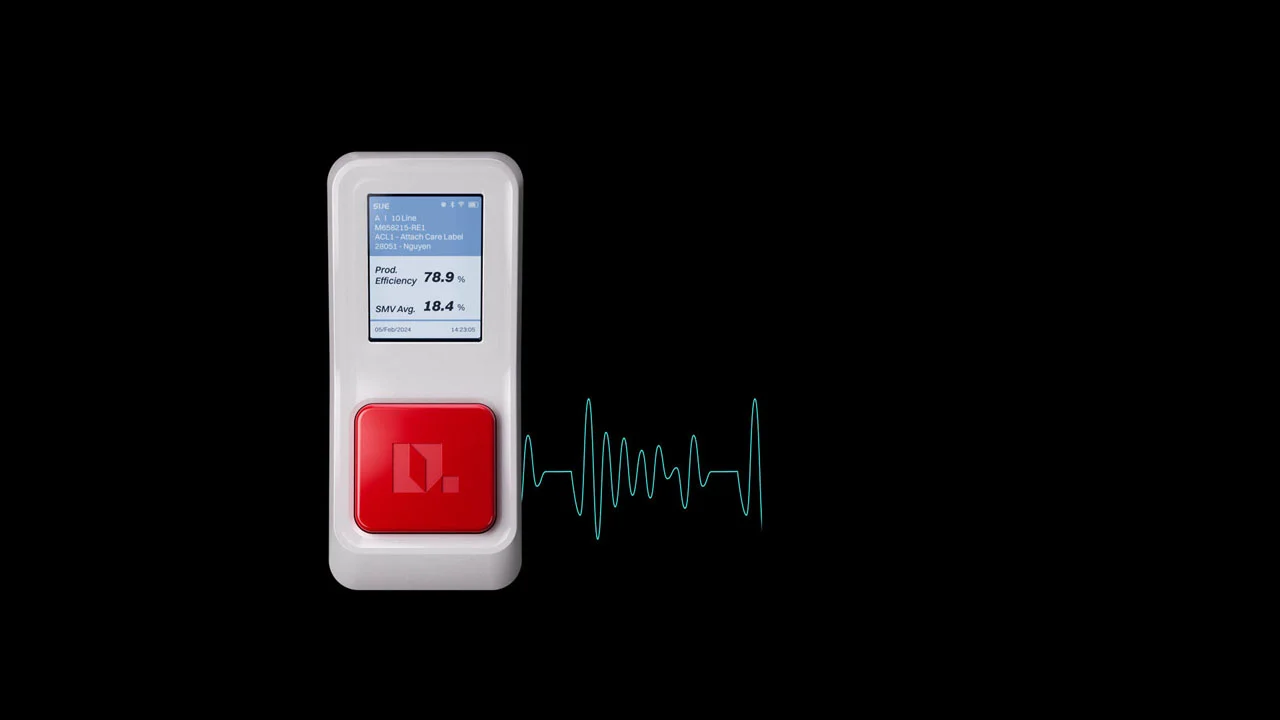

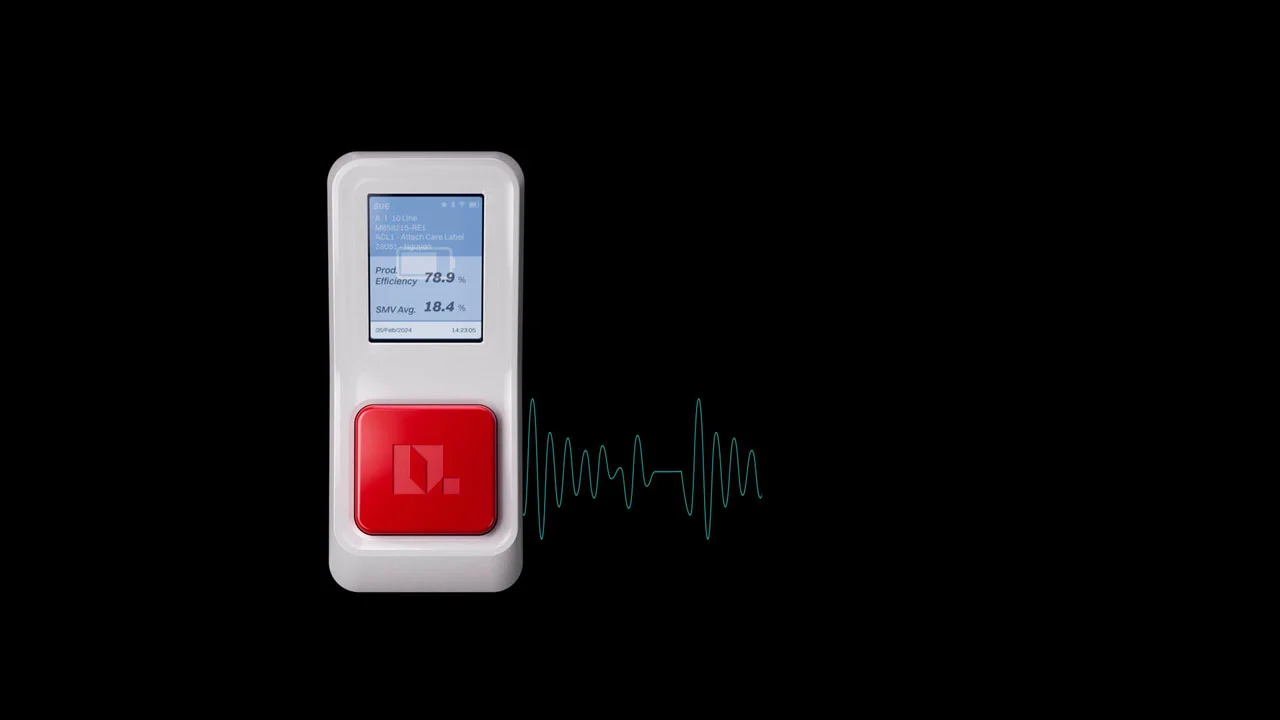

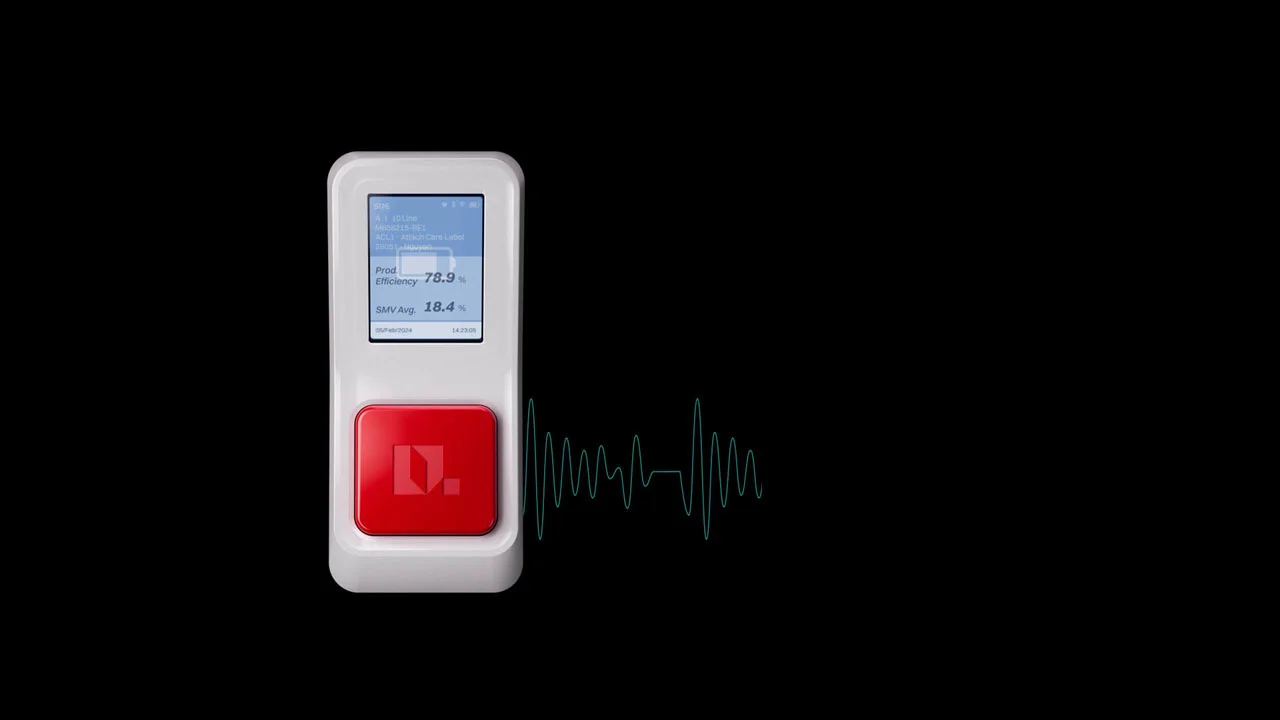

Productivity can be measured accurately by collecting 30 vibration datas per second of sewing machines while production.

Even if there is a power outage at the factory, or the internet is disconnected, we operate stably through the battery to collect data without any issues.

Pressing the red button in every time it's compeleted will update the production quantity and average SMV in real time.

Productivity can be measured accurately by collecting 30 vibration datas per second of sewing machines while production.

Even if there is a power outage at the factory, or the internet is disconnected, we operate stably through the battery to collect data without any issues.

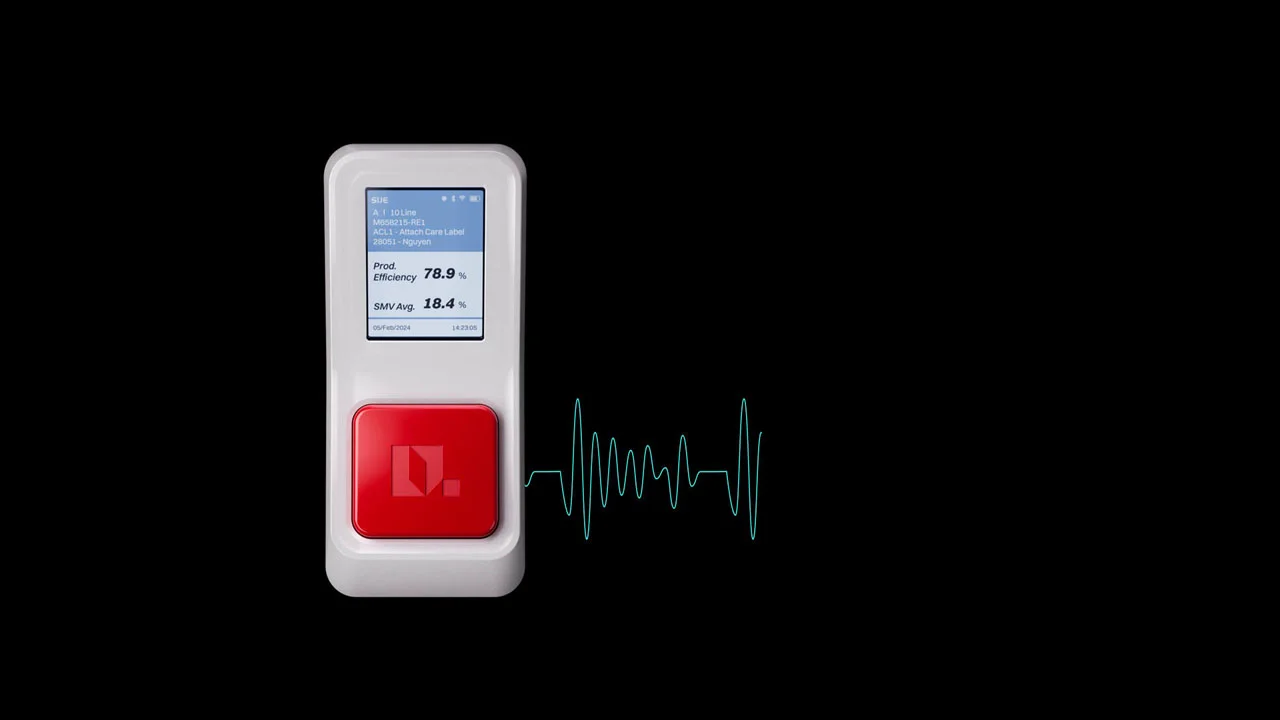

How the vibration of sewing machines become data

Colleting of

microvibration on site

Colleting of microvibration on site

Production vibration collection of sewing machine

Fine Vibration

+ Production Vibration

Fine Vibration + Production Vibration

Colleting of microvibration on site

Production vibration collection of sewing machine

Fine Vibration + Production Vibration

Actual usage example

For industrial digital transformation,

a neural network connecting the physical and virtual area is required.

For industrial digital transformation, a neural network connecting the physical and virtual area is required.

For industrial digital transformation, a neural network connecting the physical and virtual area is required.

The system constructs a neural network of information

that can be utilized in MES, ERP (Levels 4 and 5)

for the current status of the factory (Level 1).

The system constructs a neural network of information

that can be utilized in MES, ERP (Levels 4 and 5)

for the current status of the factory (Level 1).

Digital

neural network

area

Digital

neural network area

Level 1

Level 1

Field Device Status in the factory

Field Device Status in the factory

Import, Inspection, Cutting, Production, QC, Trimming, Export

Level 2

Level 2

Control Network information collection

Control Network information collection

RTU, PLC, communication protocol, parameter control

RTU, PLC, communication protocol, parameter control

Level 3

Level 3

RTU, PLC, communication protocol, parameter control

Process Network Information Transmission

Process Network Information Transmission

Database Management (SCADA, KANBAN)

Level 4

Manage&Operate Production Execution

MES

Level 4

Manage&Operate Production Execution

MES

Level 4

Manage&Operate Production Execution

MES

Level 5

Corporation System Resource Management

ERP

Level 5

Corporation System Resource Management

ERP

Level 5

Corporation System Resource Management

ERP

SMV calculated through

vibration data, production efficiency, and loss rate

SMV calculated through vibration data, production efficiency, and loss rate

1

1

SMV

SMV

Standard Working Hours:

Time focused on production

2

2

Efficiency

Efficiency

Efficiency of production:

Allowable standard time

3

3

Loss Rate

Loss Rate

Non-Productive Time:

Wasted time during working hours

SMV calculated through vibration data, production efficiency, and loss rate

Through data parsing, quickly identify the SMV.

Derive SMV from numerous cycle times performed in a single process.

We compare the analyzed SMV with the actual production cycle time in real time.

Through data parsing, quickly identify the SMV.

Derive SMV from numerous cycle times performed in a single process.

We compare the analyzed SMV with the actual production cycle time in real time.

Through data parsing, quickly identify the SMV.

Derive SMV from numerous cycle times performed in a single process.

We compare the analyzed SMV with the actual production cycle time in real time.

Through data parsing, quickly identify the SMV.

Derive SMV from numerous cycle times performed in a single process.

We compare the analyzed SMV with the actual production cycle time in real time.

Through data parsing, quickly identify the SMV.

Derive SMV from numerous cycle times performed in a single process.

We compare the analyzed SMV with the actual production cycle time in real time.

Through data parsing, quickly identify the SMV.

Derive SMV from numerous cycle times performed in a single process.

We compare the analyzed SMV with the actual production cycle time in real time.

Through data parsing, quickly identify the SMV.

Derive SMV from numerous cycle times performed in a single process.

We compare the analyzed SMV with the actual production cycle time in real time.

Through data parsing, quickly identify the SMV.

Derive SMV from numerous cycle times performed in a single process.

We compare the analyzed SMV with the actual production cycle time in real time.

Carrying out effective improvement activities

to increase production efficiency with data.

By quantifying the roughly estimated efficiency,

you can establish efficiency enhancement strategies

for processes, lines, and plants.

Carrying out effective improvement activities

to increase production efficiency with data.

By quantifying the roughly estimated efficiency,

you can establish efficiency enhancement strategies

for processes, lines, and plants.

Analysis of work patterns

Analysis of work patterns

Notify when abnormal patterns occur

based on repetitive patterns

Notify when abnormal patterns occur

based on repetitive patterns

Line Balancing

Line Balancing

Indicate and address imbalances in workload

per process

Indicate and address imbalances in workload

per process

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

Individual management of worker

Individual management of worker

Human resources management

as a quantitative measure of workers' productivity skills

Human resources management

as a quantitative measure of workers' productivity skills

The transmitted data is provided as real-time indicators

so that problems can be immediately resolved

through on-site monitoring.

The transmitted data is provided as real-time indicators

so that problems can be immediately resolved

through on-site monitoring.

The transmitted data is provided as real-time indicators

so that problems can be immediately resolved

through on-site monitoring.

The data analyzing actual production time is stored in the DB,

and it becomes the process analysis data of Monolis.

Company name

Sije

Customer Service

+82(0)2-1644-4386

sije@sijecorp.com

Address

Main Office: 12, Gaetbeol-ro, Yeonsu-gu, Incheon, Republic of Korea

R&D Center: 14-6, Teheran-ro 78-gil, Gangnam-gu, Seoul, Republic of Korea

CEO: Shin In Jun Business Registration No: 444-88-02133

Copyright© 2024, Sije. All right reserved.

Company name

Sije

Customer Service

+82(0)2-1644-4386

sije@sijecorp.com

Address

Main Office: 12, Gaetbeol-ro, Yeonsu-gu, Incheon, Republic of Korea

R&D Center: 14-6, Teheran-ro 78-gil, Gangnam-gu, Seoul, Republic of Korea

CEO: Shin In Jun Business Registration No: 444-88-02133

Copyright© 2024, Sije. All right reserved.

+82(0)2-1644-4386

sije@sijecorp.com

Main Office

12, Gaetbeol-ro, Yeonsu-gu, Incheon, Republic of Korea

R&D Center

14-6, Teheran-ro 78-gil, Gangnam-gu, Seoul, Republic of Korea

CEO : Shin In Jun

Business Registration No : 444-88-02133

Copyright © 2024, Sije. All rights reserved.

The data analyzing actual production time is stored in the DB, and it becomes Monolis' process analysis data.