The starting point of a journey

We will use IT to optimize sourcing and production, shaping the future of apparel.

In the future, good clothes may no longer be as affordable as they are today.

The clothing industry's complex production structure faces limitations.

Property

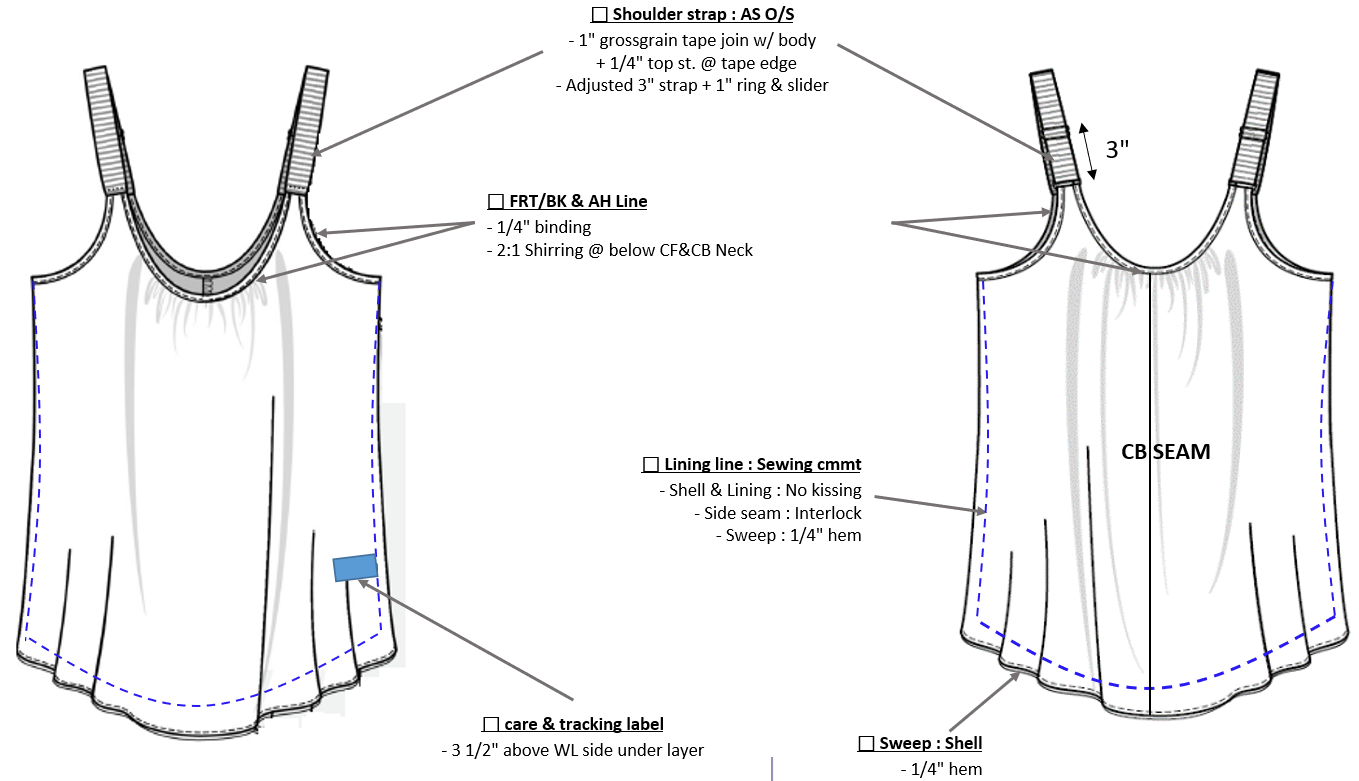

The delicate nature of clothing challenges both standardization and automation.

Off-Shoring

The clothing industry relies on labor-intensive methods and low-cost production in developing countries.

Technology

Rapid advancements bring sewing robots closer, highlighting the need for future autonomous manufacturing.

Present

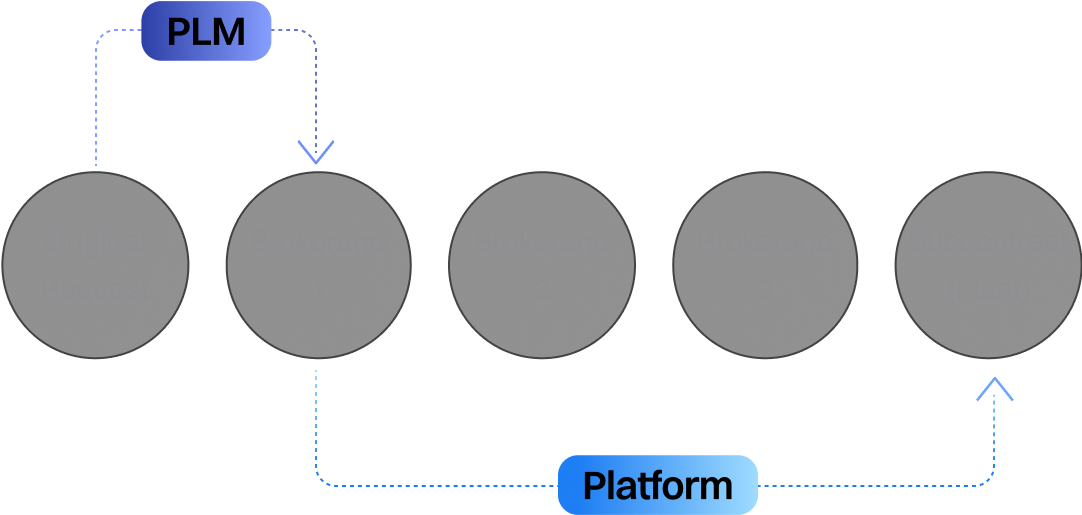

The clothing supply chain includes brands, traders, and factories, with intricate interconnections across departments, making communication difficult.

Problem

The real challenge for the clothing supply chain begins now. Beyond rising labor and material costs, the industry faces growing uncertainties and a range of issues to address.

from. Chat GPT (2024.10)

1

Cost

Economical

2

Time

Physical

3

Human

Technical

1

Cost

Economical

2

Time

Physical

3

Human

Technical

1

Cost problems

The core of the global clothing supply chain is creating quality products at low costs. This issue cannot be resolved solely through offshoring or the adoption of smart factories.

2

Time problems

Reducing inefficiencies is crucial for cost-effective production. Traditional ERP systems alone cannot fully address the complexities of the supply chain.

3

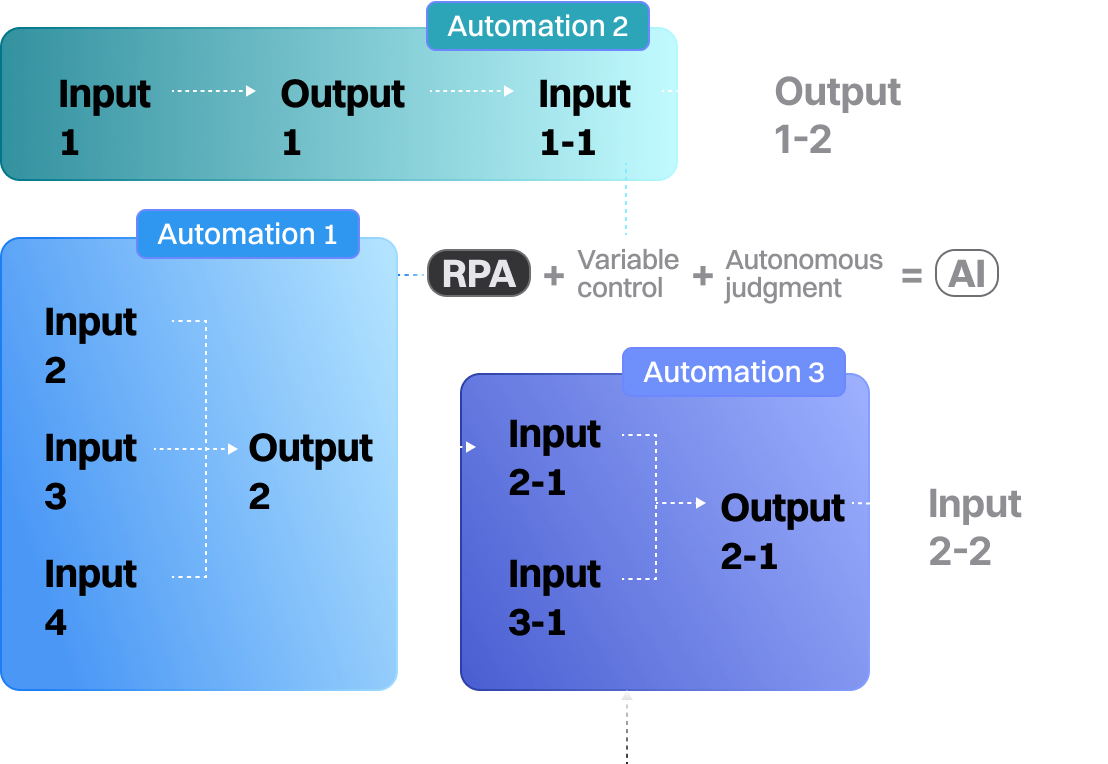

Human problems

We implement modular automation to handle specialized tasks and develop AI systems to manage external variables.

We address clothing industry challenges with IoT for real-time sewing monitoring and SaaS for end-to-end process integration.

PoC

In fact, our customers are innovatively in hence productivity.

Increased productivity

+23.5%

Performance in the fourth quarter of 2023

Data collection

+193 tb

Data from February to November 2023

Cost Save

Improved production efficiency

Improved work efficiency

Reduce Processing costs

$1.50 >

$1.00

33.4%

Minimize Office staff

$3.00 >

$0.50

83.4%

Time Efficiency

90%

Expert Replacement

X8

SIJE aims to be a platform integrating food, clothing, and shelter.

Annual production

120 billion

Number of workers in 2022 : 80Million

Turnover

$ 3 trillion

$2 trillion in annual transactions by 2022

Number of workers

80 million

2022 Annual production of 120 billion pieces

~ ₩ 600 B

SOM

Apparel manufacturing IT software market

~ ₩ 14 T

SAM

Smart Solutions Market for Garment Industry

~ ₩ 187.5 T

TAM

5% of the global clothing market

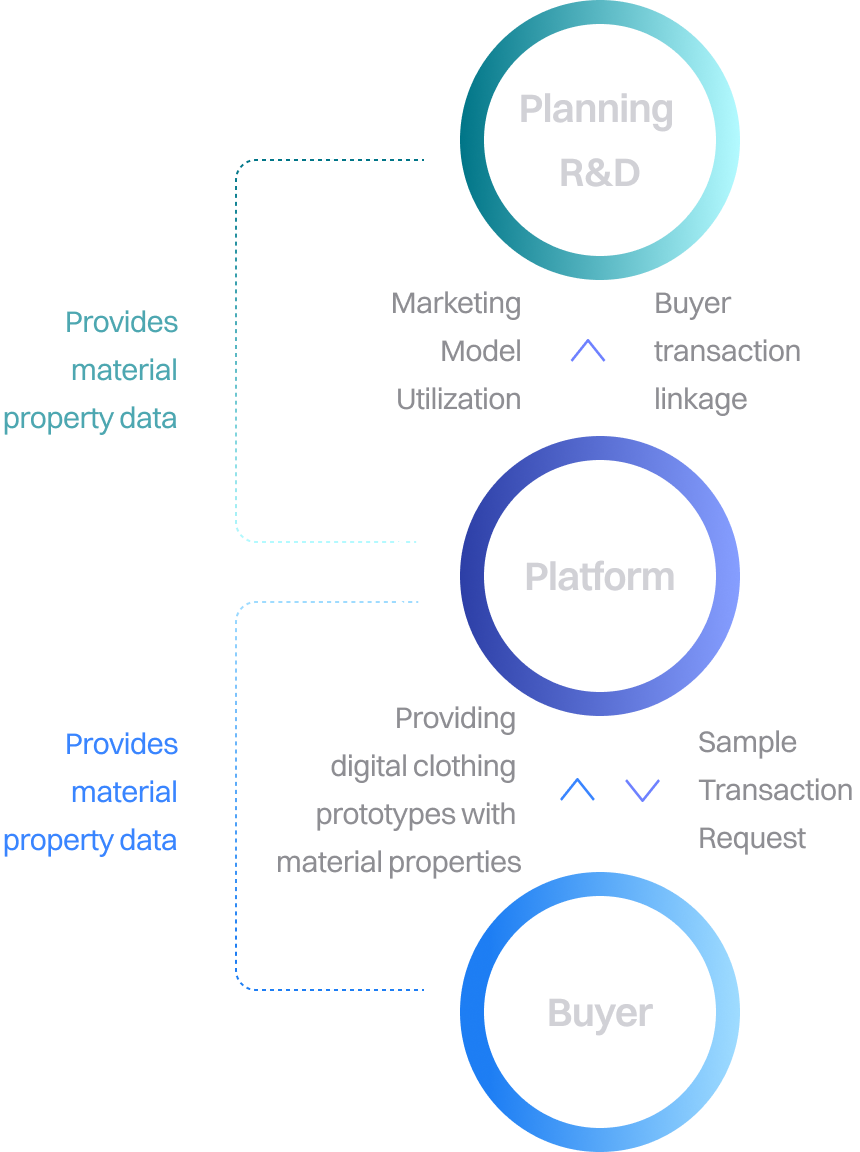

Big data drives digital transformation in the clothing industry

Fashion companies can simulate demand by location and SKU, enabling quick decisions and reducing inventory risks.

Mission

SIJE uses advanced IT to make apparel a key industry of the future.